Method and device for simultaneously measuring reflection and transmission distortion difference of optical element

A technology of reflective transmission and optical components, applied in the field of optical measurement, can solve problems that affect the accuracy of measurement, inaccurate measurement results, and increase system complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

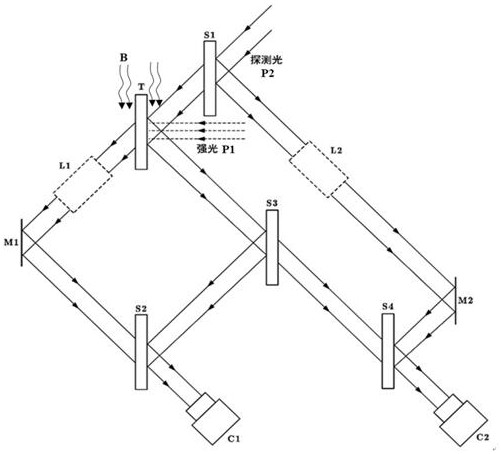

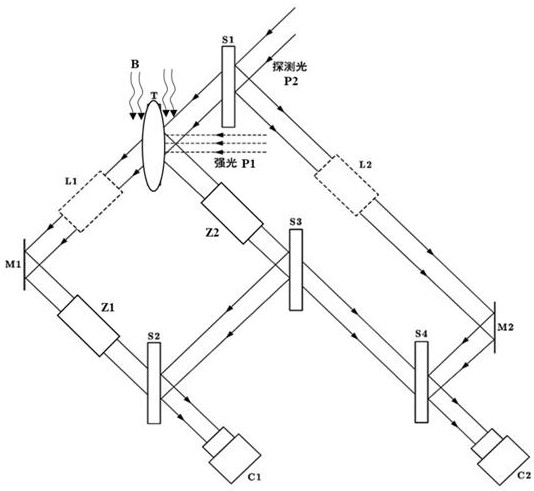

[0037]refer to figure 2 , this embodiment provides a device for simultaneously measuring reflection and transmission distortion of optical elements, including a detection light source P2, a first half mirror S1, a second half mirror S2, a third half mirror S3, The first optical path difference adjusting mechanism L1, the first mirror M1 and the first camera C1.

[0038] The detection light source P2 is incident on the first half-mirror S1 at an incident angle of 45°, and the first half-mirror S1 is parallel to the sample T to be tested. In this embodiment, the sample T to be tested has a flat front and rear surface. Plane mirror. The transmitted light transmitted by the first half-mirror S1 is used as the probe light, and the probe light is incident on the sample T to be tested at an incident angle of 45°, and after passing through the sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com