A method and device for simultaneously measuring reflection and transmission distortion of optical elements

A technology of reflective transmission and optical components, applied in the field of optical measurement, can solve problems such as increasing system errors, affecting measurement accuracy, increasing system complexity, etc., and achieves the effect of simple and compact structure and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further described below with reference to the accompanying drawings and specific embodiments.

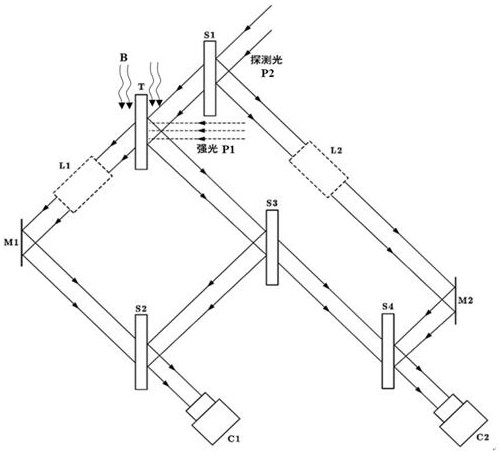

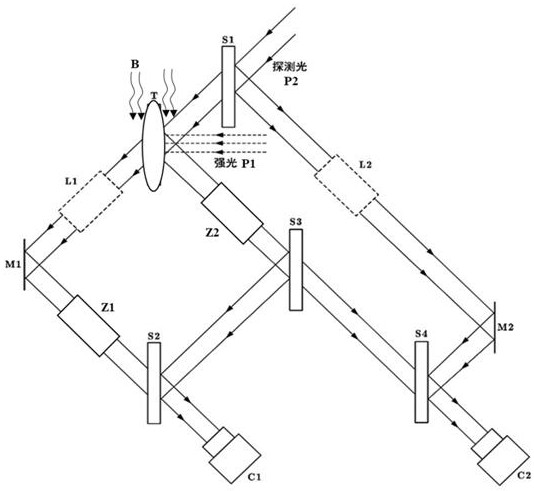

[0037]Refer figure 2 This embodiment provides a device that simultaneously measures the difference in reflective transmission distortion of the optical element, including detecting the light source P2, the first transmissive halfway S1, the second semi-transmissive mirror S2, the third semi-transmissive mirror S3, The first optical path differential mechanism L1, the first mirror M1, and the first camera C1.

[0038] The detective light source P2 is incident on the first half transmissive angle to the first half transmissive angle, and the first translucent semi-inverted mirror S1 is parallel to the sample T, and the sample T is tested in the present embodiment is planar. Plane mirror. Transmitted light transmitted by the first half-transverse mirror S1 as a probe light, detecting light at an incident angle of 45 ° to the sample T, after the sample T is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com