Easy-to-expand butterfly-shaped leading-in optical cable, photoelectric composite cable and construction method thereof

A technology that introduces optical cables and is easy to expand. It is used in the installation of optical fibers/cables, power cables and cables including optical transmission components, and can solve the problems of inconvenient expansion and construction of butterfly optical cables, and achieve excellent fixing effect, easy assembly and The effect of laying and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

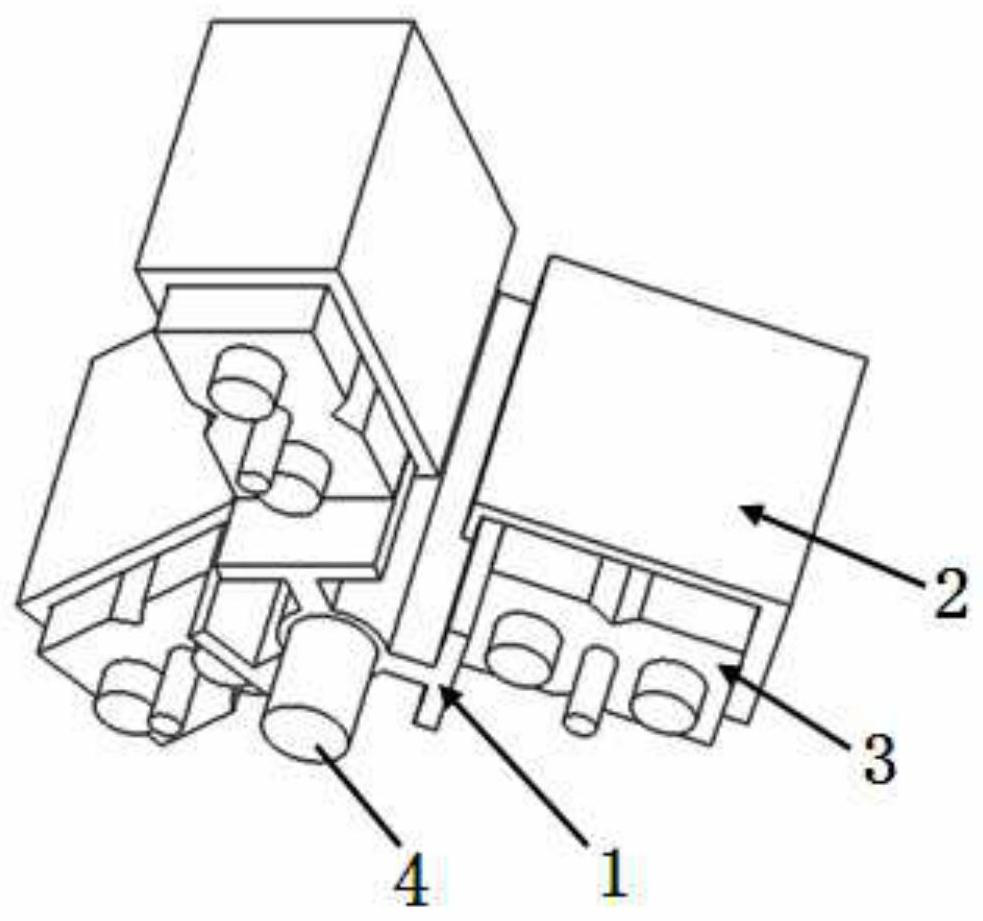

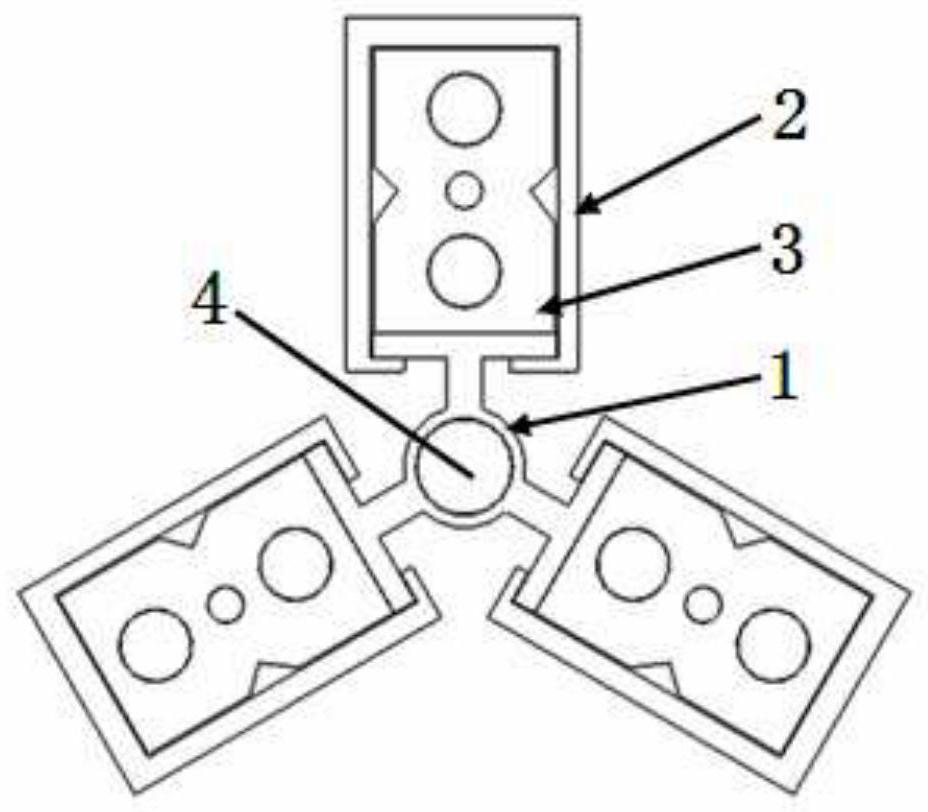

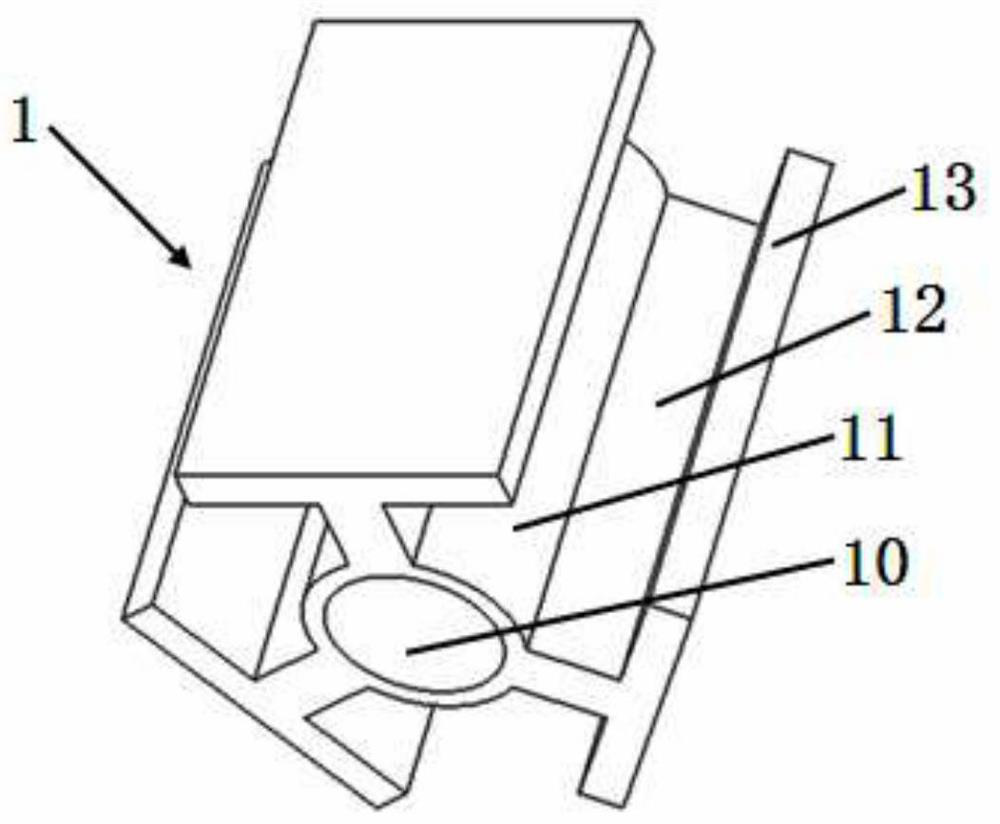

[0062] please see Figure 1 to Figure 7 , an easy-to-extend butterfly-shaped lead-in optical cable, has a skeleton part 1, three extension parts 2, three butterfly-shaped light units 3, and a central reinforcement 4. The butterfly-shaped light unit 3 is composed of a butterfly-shaped light unit sheath 31, a light The transmission part 32 and two strengthening elements 33 are composed. The light transmission part is located in the center of the butterfly optical unit sheath, and the two strengthening elements are respectively located above and below the light transmission part. The butterfly light unit sheath connects the light transmission part and the strengthening element Coated, there are tear openings 34 on the edges of the sheath of the butterfly-shaped light unit on the left and right sides of the light transmission part; Composed of engaging parts 13, the frame body 11 has a central cavity 10 inside, and one end of the three frame extension bars 12 extends outward from ...

Embodiment 2

[0064] please see Figure 8 ,refer to Figure 1 to Figure 7 , an easy-to-extend butterfly-shaped lead-in optical cable, which is basically the same as in Example 1, except that the central strengthening member is replaced by a heat-shrinkable tube 5 .

Embodiment 3

[0066] please see Figure 9 ,refer to Figure 1 to Figure 8 , an easy-to-extend butterfly-shaped lead-in optical cable, basically the same as the embodiment 2, the difference is that: the heat-shrinkable tube 5 has a heat-shrinkable groove 51, and the skeleton body has a skeleton body groove 16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com