Intraocular lens positioner

An intraocular lens and locator technology, applied in the field of medical devices, can solve the problems that are not conducive to guaranteeing the quality of the operation and the high requirements for the doctor's experience level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

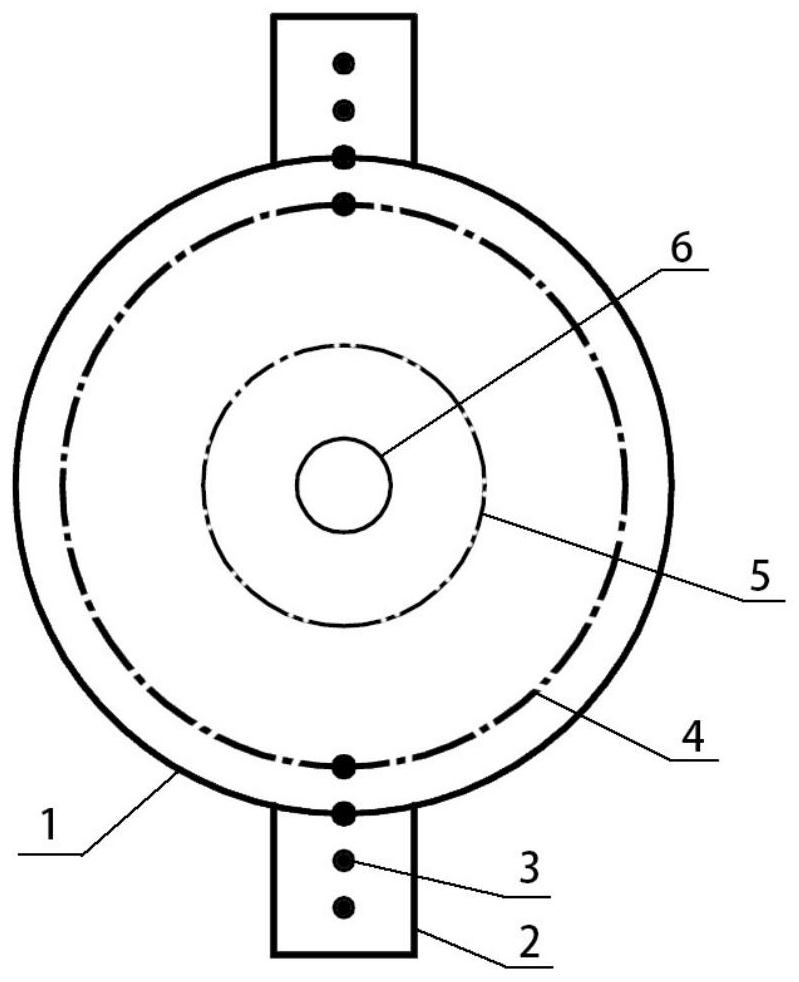

[0030] see figure 1 with Figure 4 , an intraocular lens positioner for intraocular lens suture fixation surgery, comprising a cornea part 1, the cornea part is a transparent arc body, a vent hole 6 is opened in the center of the cornea part, and a vent hole 6 is opened in the cornea part The puncture hole positioning haptic 2 is provided on the edge of 1, the intraocular lens optical part positioning line 5 is provided near the central position of the cornea part 1, and the limbal positioning line 4 is provided near the edge position of the cornea part 1.

[0031] The corneal portion 1 is made of silicon hydrogel with a water content of 36%, its diameter is 14mm, its thickness is 0.09mm, and its base arc radius is 8.6mm. The diameter of the ventilation hole 6 is 2mm. The intraocular lens The diameter of the optical part positioning line 5 is 6 mm, and the diameter of the limbal positioning line 4 is 12 mm.

[0032] Due to the different eyeball sizes of patients, the corneal...

Embodiment 2

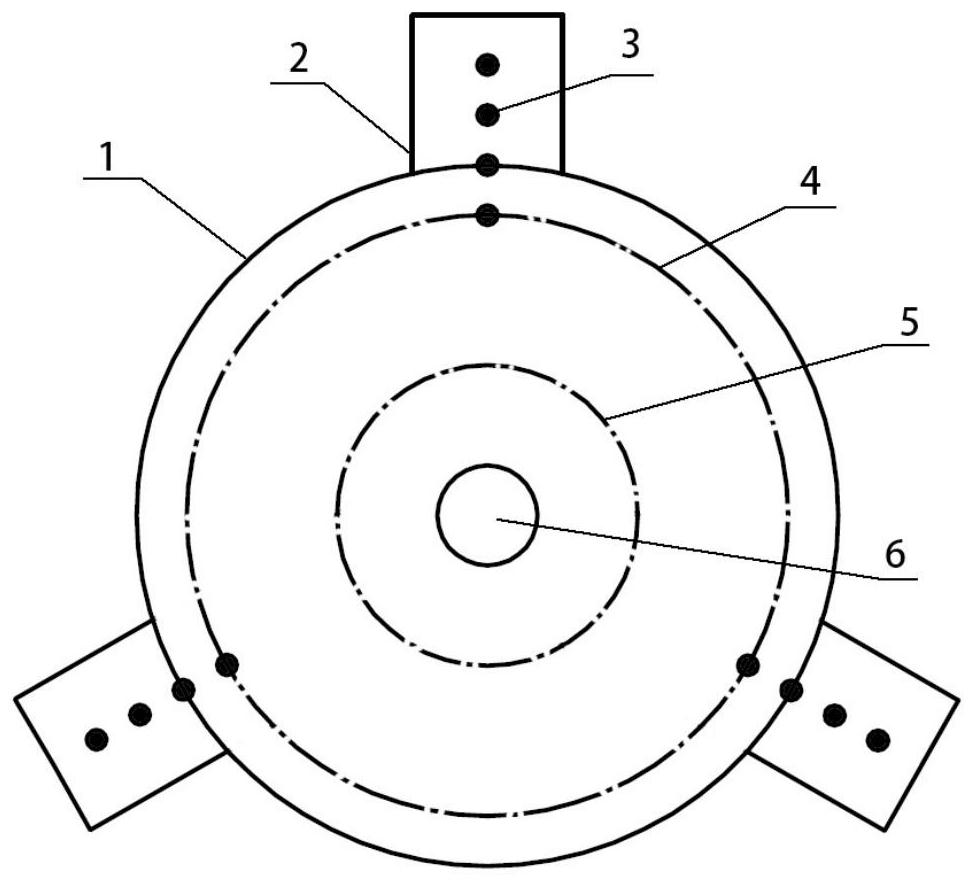

[0037] see figure 2 , an intraocular lens positioner for intraocular lens suture fixation surgery, comprising a cornea part 1, the cornea part is a transparent arc body, a vent hole 6 is opened in the center of the cornea part, and a vent hole 6 is opened in the cornea part The puncture hole positioning haptic 2 is provided on the edge of 1, the intraocular lens optical part positioning line 5 is provided near the central position of the cornea part 1, and the limbal positioning line 4 is provided near the edge position of the cornea part 1.

[0038] The corneal portion 1 is made of silicon hydrogel with a water content of 36%, its diameter is 14mm, its thickness is 0.09mm, and its base arc radius is 8.6mm. The diameter of the ventilation hole 6 is 2mm. The intraocular lens The diameter of the optical part positioning line 5 is 6 mm, and the diameter of the limbal positioning line 4 is 12 mm.

[0039] Due to the different eyeball sizes of patients, the corneal sizes are also...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com