A laser cutting process for fuel tank blanking

A laser cutting and fuel tank technology, applied in laser welding equipment, applications, manufacturing tools, etc., can solve the problems of severe reaction, inability to ensure smooth section, and achieve uniform temperature, consistency, and cutting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

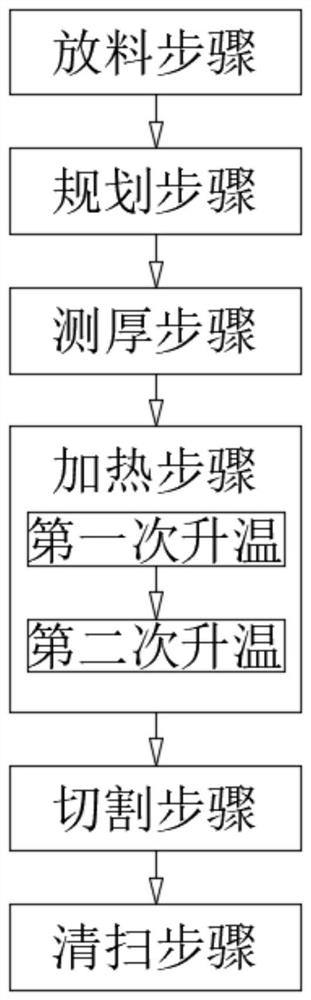

[0072] Include the following steps:

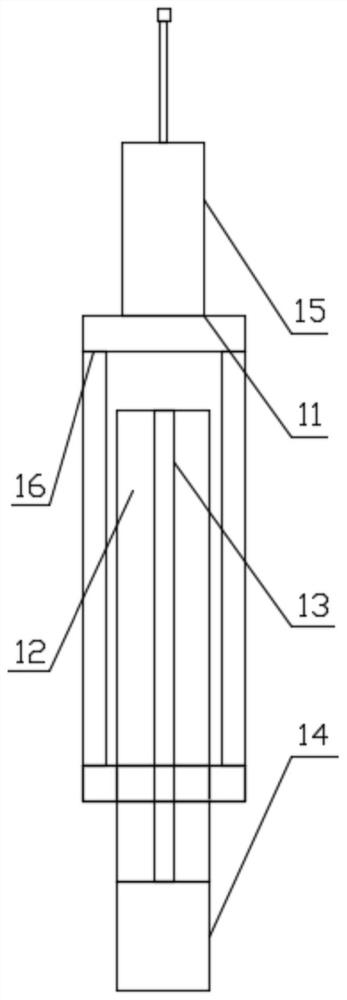

[0073] The discharging step: placing the raw material on the cutting table; several first measuring devices 11 are arranged in parallel on the cutting table; the first measuring device 11 is used to measure the height of the lower surface of the raw material;

[0074] Planning steps: use a camera to shoot the upper surface of the raw material; calculate the laser cutting path according to the shooting map;

[0075] Thickness measurement step: using a second measuring mechanism to measure the height of the upper surface of the raw material; moving the second measuring mechanism along the laser cutting path; obtaining the thickness of the raw material at multiple positions on the laser cutting path. The thickness of the raw material is 3.95 mm, 3.97 mm, 4.02 mm, and 4.05 mm.

[0076] A heating step is also included between the thickness measurement step and the cutting step; the heating step specifically includes:

[0077] The first heatin...

no. 2 example

[0083] Include the following steps:

[0084] Unloading step: Put the raw material on the cutting table. A plurality of first measuring devices 11 are arranged in parallel on the cutting table. The first measuring device 11 is used to measure the height of the lower surface of the raw material.

[0085] Planning steps: Use a camera to shoot the upper surface of the raw material. Calculate the laser cutting path based on the captured image.

[0086] Thickness measurement step: use the second measurement mechanism to measure the height of the upper surface of the raw material. The second measurement mechanism moves along the laser cutting path. Obtain the thickness of the raw material at multiple locations along the laser cutting path. The range of raw material thickness is 3.95mm, 4.01mm, 3.96mm, 4.04mm.

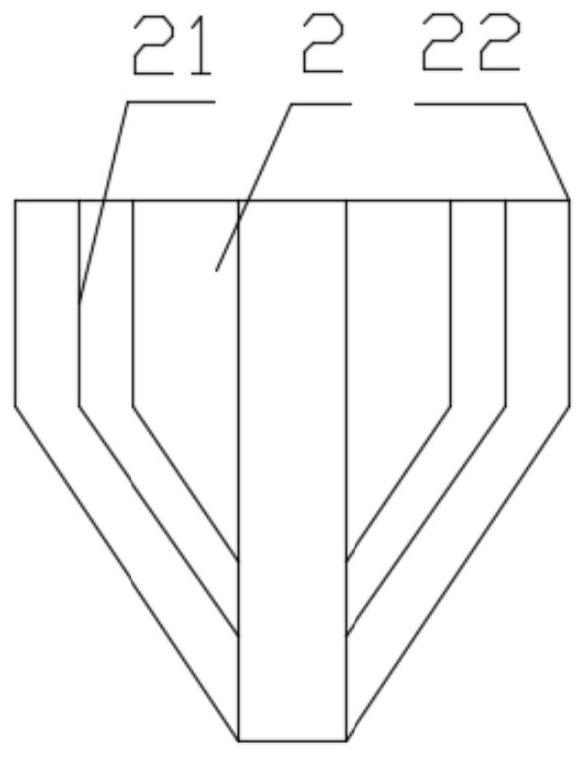

[0087]Cutting step: Use cutter 2 to emit laser to cut the raw material. The power of cutter 2 is 3000W, 3600W, 3100W and 3900W. A first nozzle 21 is provided around th...

no. 3 example

[0091] Include the following steps:

[0092] Unloading step: Put the raw material on the cutting table. A plurality of first measuring devices 11 are arranged in parallel on the cutting table. The first measuring device 11 is used to measure the height of the lower surface of the raw material.

[0093] Planning steps: Use a camera to shoot the upper surface of the raw material. Calculate the laser cutting path based on the captured image.

[0094] Thickness measurement step: use the second measurement mechanism to measure the height of the upper surface of the raw material. The second measurement mechanism moves along the laser cutting path. Obtain the thickness of the raw material at multiple locations along the laser cutting path. The range of raw material thickness is 3.97mm, 4.04mm, 4.05mm, 3.96mm.

[0095] A heating step is also included between the thickness measurement step and the cutting step; the heating step specifically includes:

[0096] The first temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com