Vacuum cavity vapor chamber water filling nozzle welding, cutting and code spraying integrated equipment

A technology of vapor chamber and vacuum chamber, which is applied in the field of welding, cutting, and coding integrated equipment for the water injection port of the vacuum chamber vapor chamber, which can solve the problems of complex and cumbersome processes, inability to achieve consistent rhythm, and waste of manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

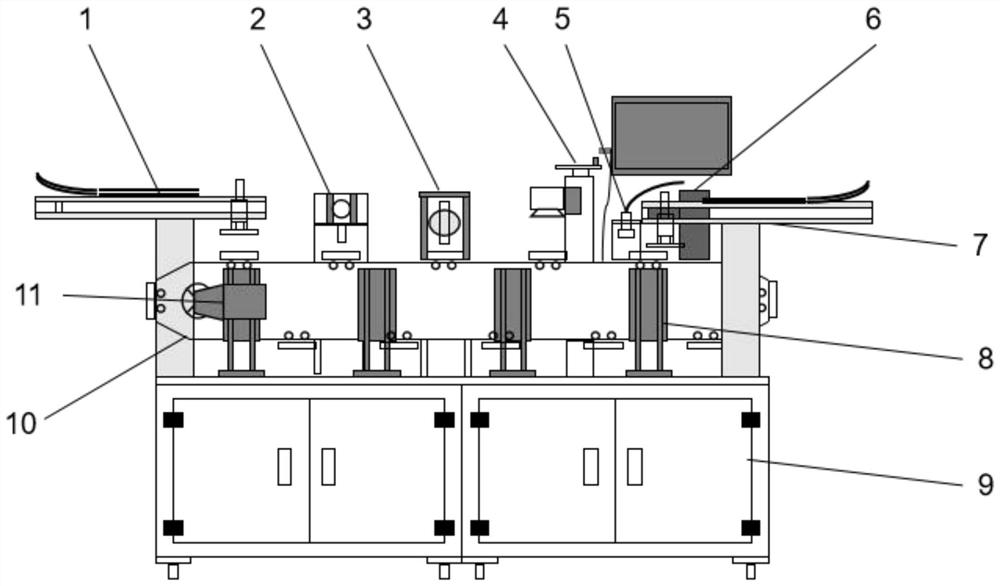

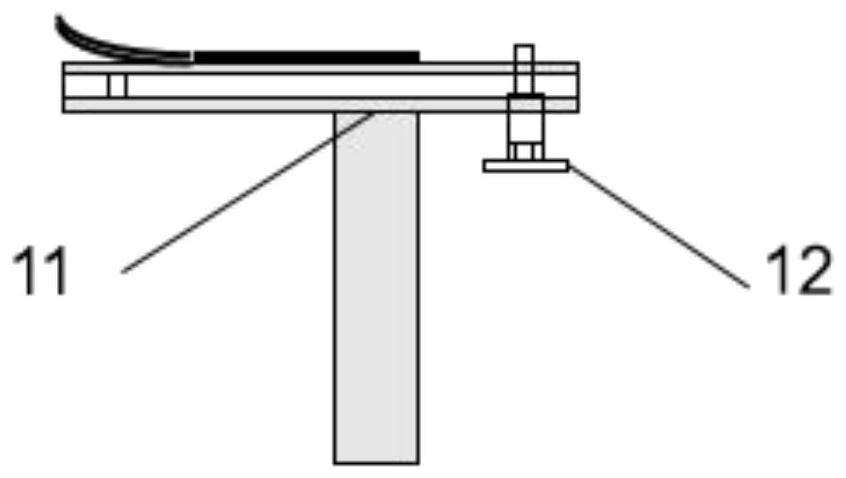

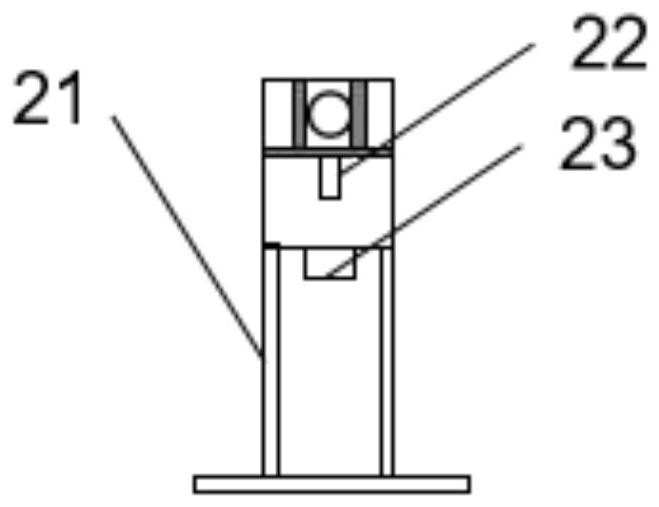

[0027] refer to figure 1 , an integrated equipment for welding, cutting, and coding at the water injection port of the soaking plate in a vacuum chamber, including: a frame 9, a vertical circular line module 10, a feeding module 1, a riveting module 2, an ultrasonic welding module 3, and a laser cutting module Module 4, coding module 5, blanking module 6 and waste recycling module 7; the vertical circular line module is fixed on the frame, and the vertical circular line module, feeding module, A riveting module, an ultrasonic welding module, a laser cutting module, a coding module, a waste recycling module and a blanking module are sequentially distributed around the vertical circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com