Material weighing and packaging scale

A technology for packaging scales and materials, which is applied in the directions of packaging, transportation and packaging, and types of packaging items. It can solve the problems of waste of materials, large space occupied by cylinders, and falling off of packaging bags, so as to achieve space saving, compact structure and stable packaging process. effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific drawings.

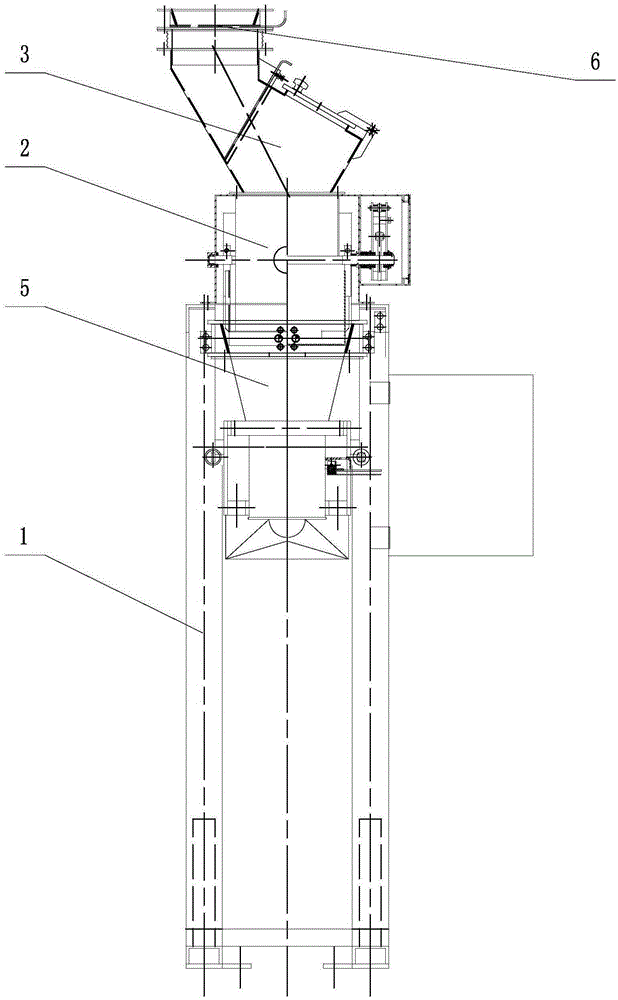

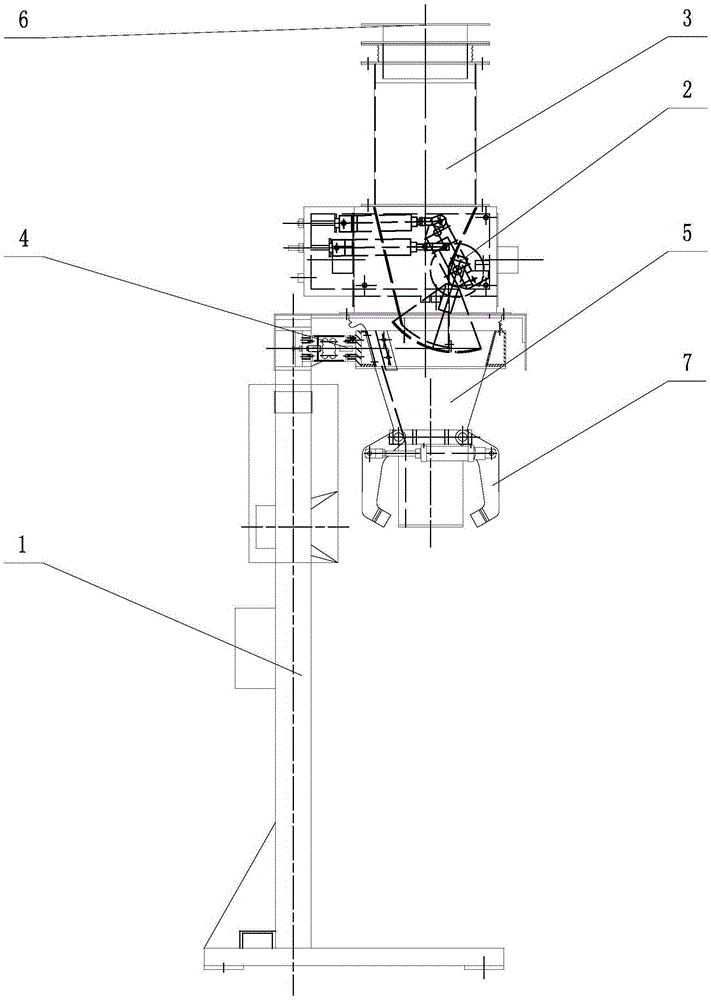

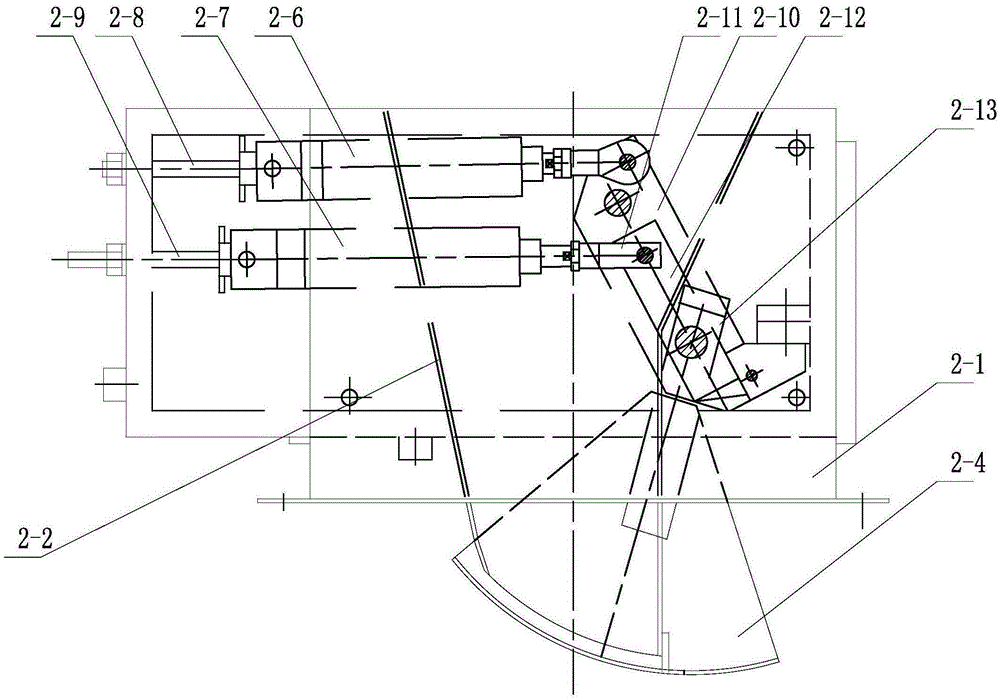

[0020] Such as Figure 1 ~ Figure 6 Shown: The packaging scale for the ingredients of various materials includes a frame 1, a feeding device 2, a distribution tank 3, a weighing scale 4, a discharge hopper 5, a flapper valve 6, a bag clamping mechanism 7, and a hopper Shell 2-1, feeding hopper 2-2, rotating shaft 2-3, sector door 2-4, driving box 2-5, first cylinder 2-6, second cylinder 2-7, first adjusting screw 2-8 , Second adjusting screw 2-9, first connecting plate 2-10, joint 2-11, second connecting plate 2-12, limiting plate 2-13, first bag clamping arm 7-1, second bag clamping Arm 7-2, clamping portion 7-3, polyurethane block 7-4, first bag clamping cylinder 7-6, second bag clamping cylinder 7-7, etc.

[0021] Such as figure 1 , figure 2 As shown, the packaging scale of the present invention includes a frame 1, on which a feeding device 2 is installed, the upper feeding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com