Automatic rust removing, cutting and paint spraying equipment for channel steel

A technology for painting equipment and channel steel, which is applied in painting booths, metal processing equipment, grinding/polishing equipment, etc., and can solve problems such as time-consuming and labor-intensive, increased steel use costs, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

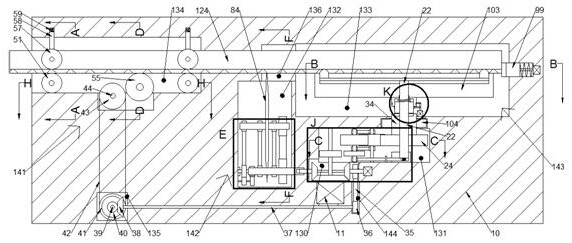

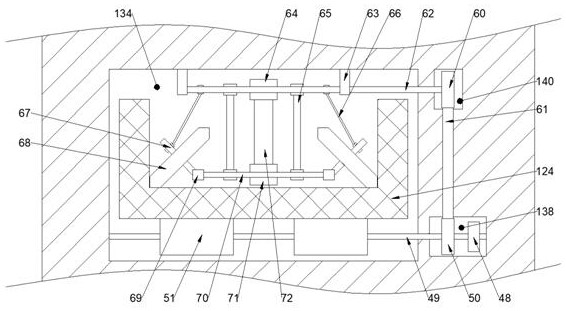

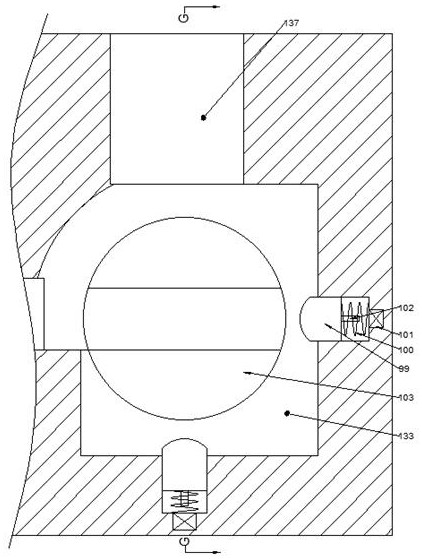

[0028] Combine below Figure 1-11 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0029] A channel steel automatic derusting, cutting, and painting equipment of the device of the present invention includes 10, the right side of the body 10 is provided with a steering cavity 133, and the lower side of the steering cavity 133 is provided with an engagement cavity 131, and the engagement cavity 131 is provided with a power chamber 130 on the lower side, and a connecting chamber 144 is provided on the lower side of the power chamber 130. A cutting chamber 132 is provided on the left side of the power chamber 130. A workpiece chamber 136 is provided on the upper side of the cutting chamber 132. The left side of the body 10 is provided with a derusting chamber 134, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com