Tool clamp for machining single-shaft shredder blade by lathe

A technology of lathe processing and tooling and fixtures, which is applied in the direction of metal processing machinery parts, manufacturing tools, metal processing equipment, etc., and can solve problems such as workpiece tilt and offset, affecting device processing accuracy, and reducing device practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

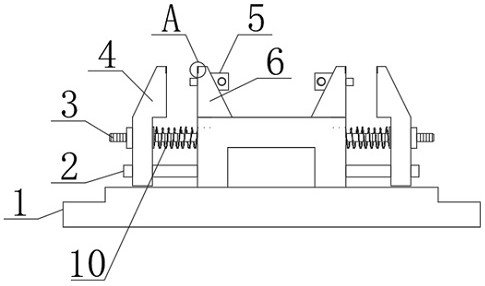

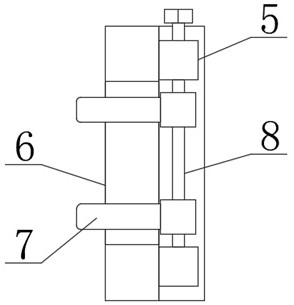

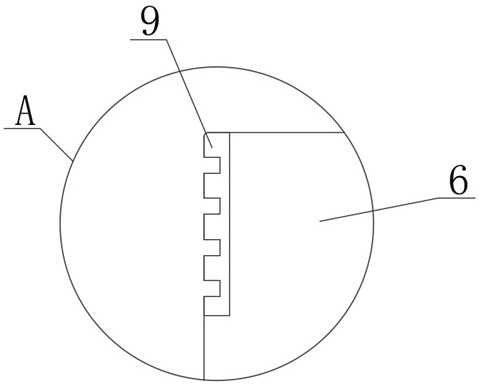

[0024] see figure 1 , figure 2 , image 3 with Figure 4 , the present invention provides a technical solution: a tooling fixture for lathe processing single-axis shredder blades, including a fixture seat 1, an integrated clamp block 6 is provided at the top edge of the fixture seat 1, and the fixture seat 1 Both sides of the top are connected with clamp arms 4, and the top sides of the fixture seat 1 are fixedly equipped with fixed rods 3 and limit rods 2. The block 6 is provided with an integrated fixed seat 5, the fixed seat 5 is screwed and installed with a screw rod 8, and the screw rod 8 is rotated with a horizontal clamping rod 7, and the inner side of the clamping block 6 is provided with a through groove, and the horizontal clamping rod One end of 7 is installed in the through groove. When the fixture is working, the workpiece can be clamped and installed stably by the horizontal clamp rod 7 and the clamp arm 4 to ensure the stability of the workpiece and prevent ...

Embodiment 2

[0027] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , the present invention provides a technical solution: a tooling fixture for lathe processing single-axis shredder blades, including a fixture seat 1, an integrated clamp block 6 is provided at the top edge of the fixture seat 1, and the fixture seat 1 Both sides of the top are connected with clamp arms 4, and the top sides of the fixture seat 1 are fixedly equipped with fixed rods 3 and limit rods 2. The arm 4 is provided with an integrated fixed seat 5, the fixed seat 5 is screwed and installed with a screw rod 8, and the screw rod 8 is rotated with a horizontal clamping rod 7, the inner side of the clamp arm 4 is provided with a through groove, and the horizontal clamping rod One end of 7 is installed in the through groove. When the fixture is working, the workpiece can be clamped and installed stably by the horizontal clamp rod 7 and the clamp arm 4 to ensure the stability of the workpiece and preven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com