Slotted hole cleaning device for die machining

A mold processing and cleaning device technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of poor cleanliness, troublesome slot cleaning, and easy sticking of debris on the hole wall, etc., to achieve The effect of wide application range and saving operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

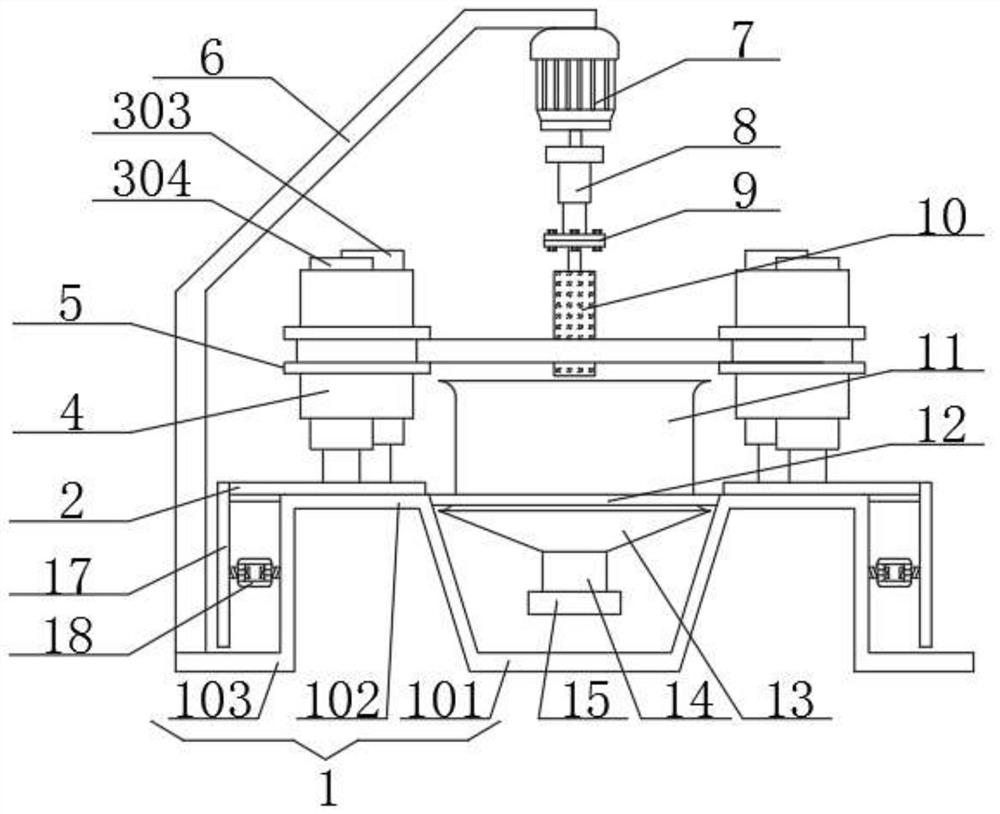

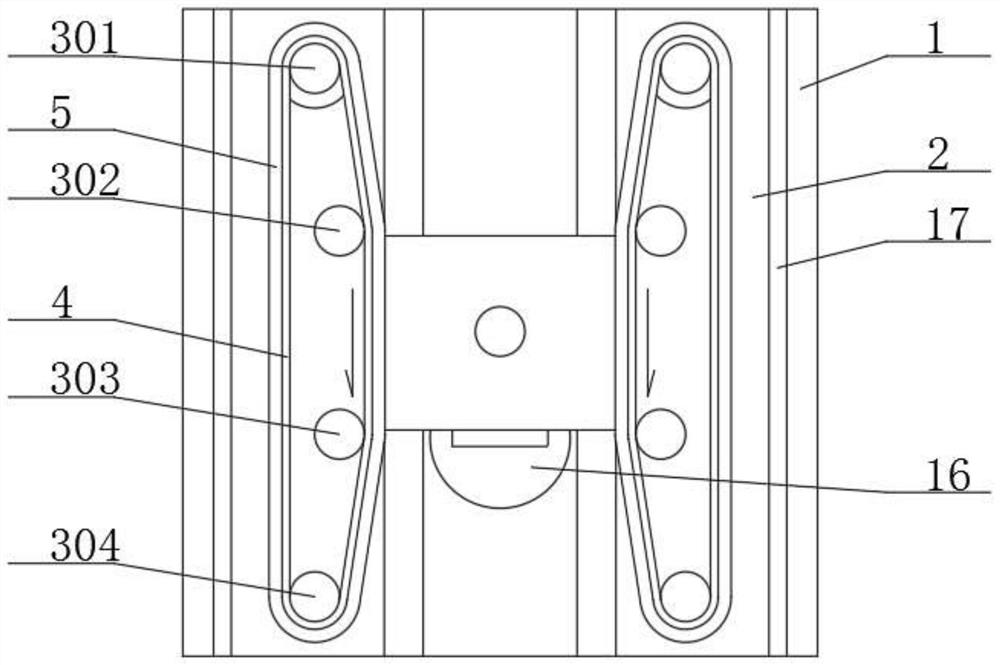

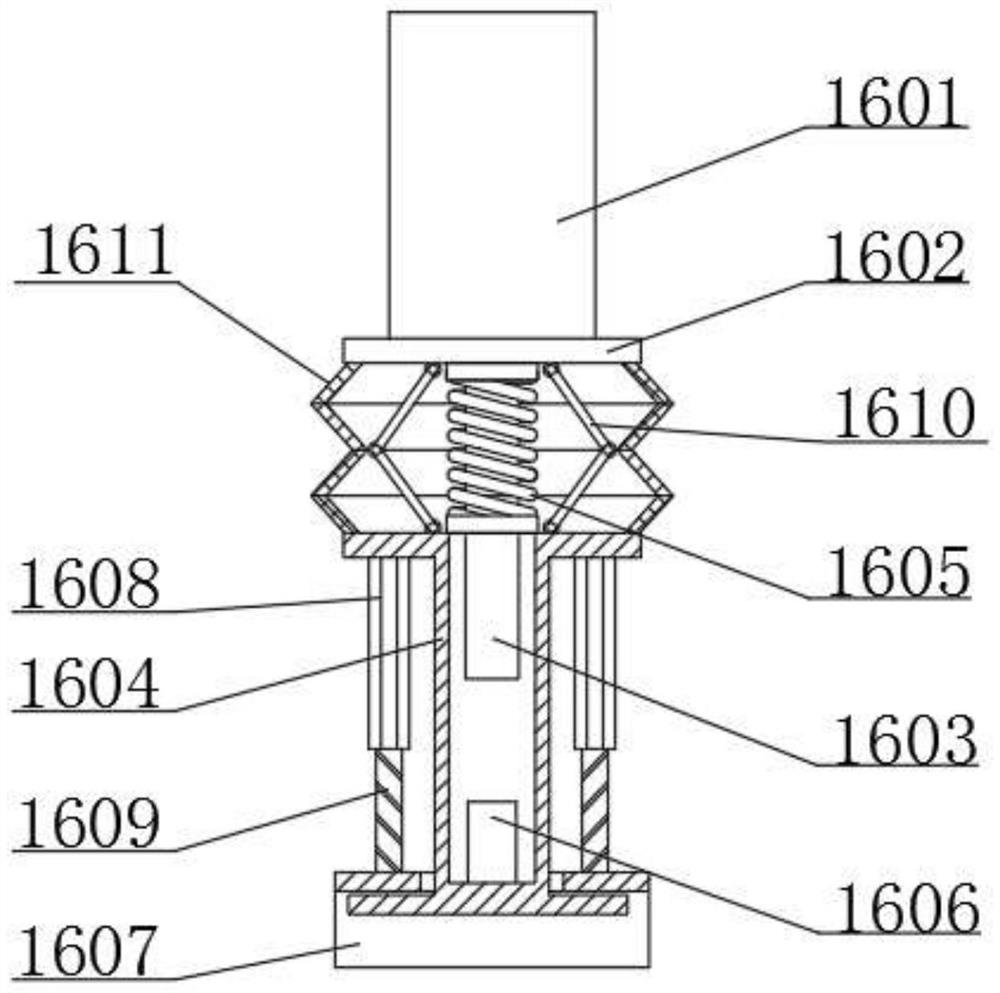

[0032] Such as Figure 1-3 As shown, a slot cleaning device for mold processing includes a support base 1, two backing plates 2 are connected to the support base 1, each backing plate 2 is provided with a roller group, and the roller group is connected to a transmission belt 4 , the outer wall of the transmission belt 4 is connected with a U-shaped clamping piece 5,

[0033] The roller set is composed of a first roller 301, a second roller 302, a third roller 303 and a fourth roller 304, and the first roller 301, the second roller 302, the third roller 303 and the fourth roller 304 are all rotatably connected with the backing plate 2 , the line connecting the center points of the first roller 301, the second roller 302, the third roller 303 and the fourth roller 304 is an isosceles trapezoid, the support base 1 is connected with a support rod 6, and the lower end surface of the support rod 6 is connected with a motor 7. An electric push rod 8 is connected to the output end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com