End face diamond grinding wheel with cooling channel

A diamond grinding wheel and cooling channel technology, which is applied to the field of end face diamond grinding wheels, can solve the problems of easy burns on the grinding surface of the workpiece, increased grinding temperature, and low grinding wheel life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

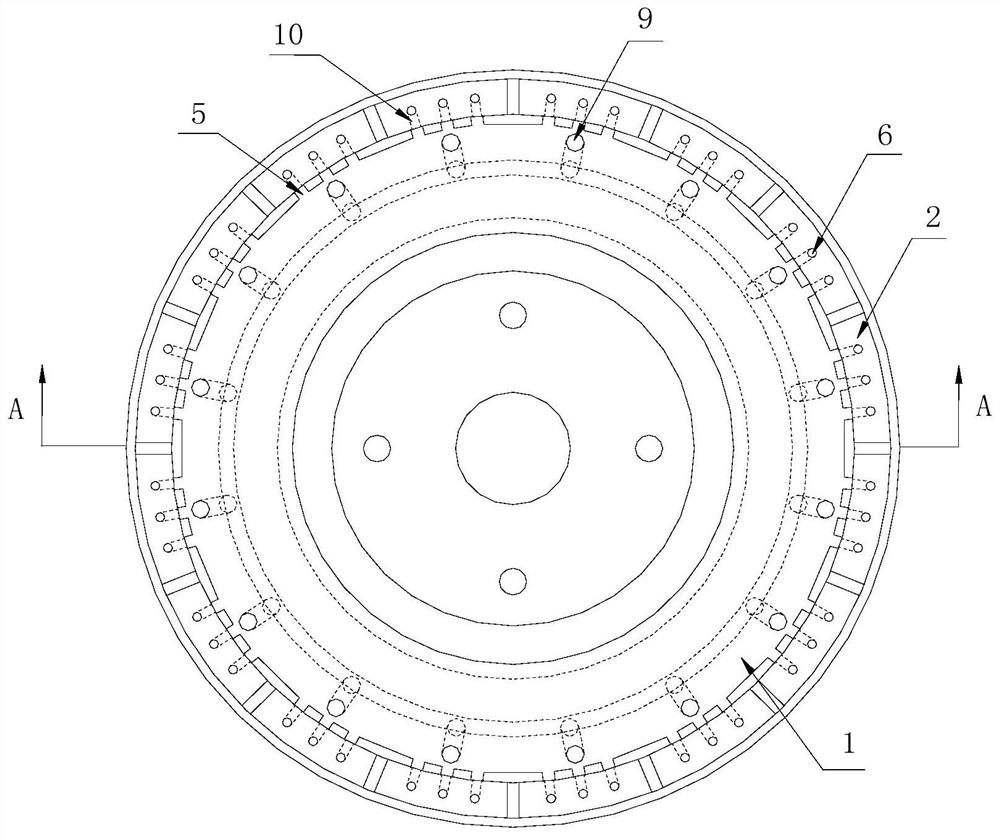

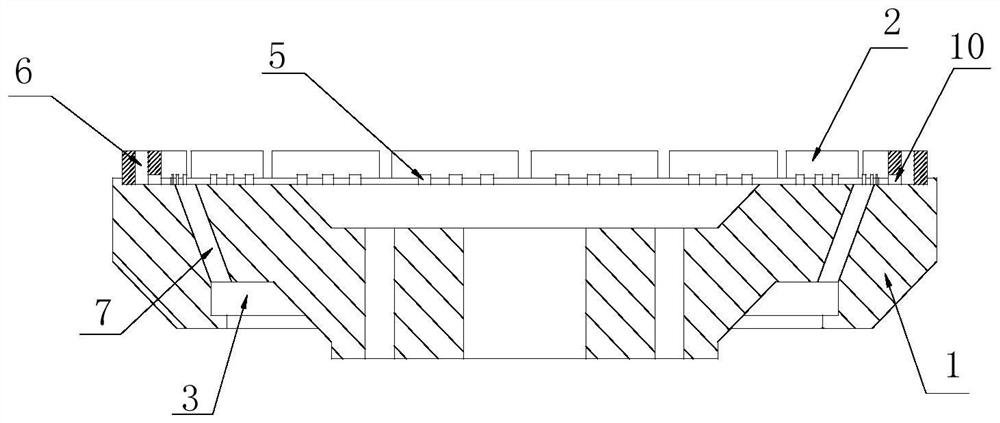

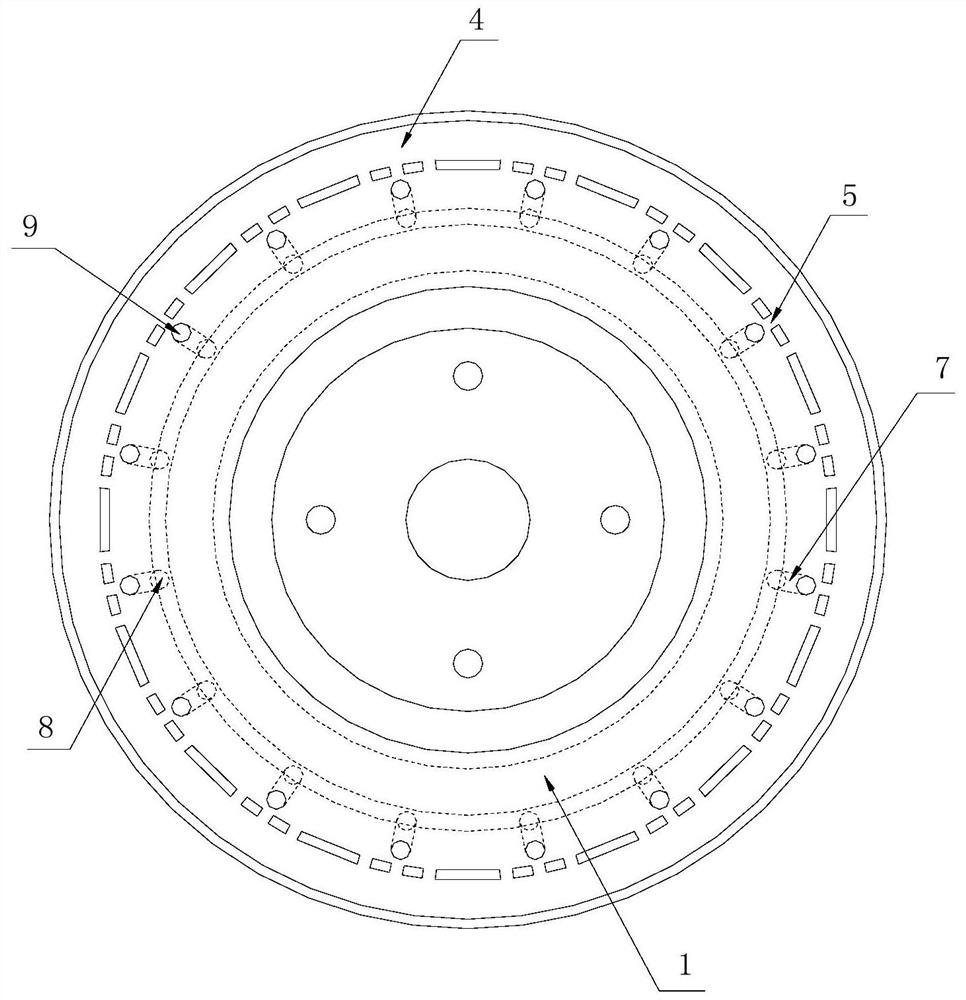

[0032] Such as Figure 1 to Figure 5 As shown, a face diamond grinding wheel provided with a cooling channel includes a grinding wheel base 1 and a diamond agglomerate 2 . Among them, the diamond agglomerate 2 refers to a block with a certain shape formed by bonding the diamond abrasives together with a binder, and the end face diamond grinding wheel refers to a grinding wheel formed by fixing the diamond agglomerate to the working surface of the grinding wheel base 1 .

[0033] Specifically, an installation groove 4 is opened on the working surface of the grinding wheel base 1 , and the diamond agglomerate 2 is located in the installation groove 4 . Preferably, the installation groove 4 is set as an annular structure, and at the same time, the diamond agglomerates 2 are bonded and fixed in the installation groove 4 at intervals and evenly, that is to say, the diamond agglomerates 2 are provided with multiple pieces at intervals, and the diamond agglomerates 2 are arranged at...

Embodiment 2

[0039] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

[0040] The diamond agglomerates 2 are metal bond diamond agglomerates, and 16 diamond agglomerates 2 are bonded and fixed in the installation groove 4, and the adjacent diamond agglomerates 2 are equally spaced.

[0041] A total of 16 introduction holes 7 are provided on the grinding wheel base 1, and three transition grooves 10 are provided on each diamond agglomerate 2. Correspondingly, three cooling grooves 5 are provided corresponding to the transition grooves 10 below each diamond agglomerate 2. The center of the liquid outlet 9 of the inlet hole is aligned with the cooling groove 5 below the diamond agglomerate 2 and in the middle, that is, the center of the liquid outlet 9 of the inlet hole is aligned with the transition groove 10 in the middle. At the same time, three cooling holes 6 are opened on each diamond agglomerate 2 . To sum up, there is a one-to-one corr...

Embodiment 3

[0044] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

[0045] The diamond agglomerates 2 are metal bond diamond agglomerates, 14 diamond agglomerates 2 are bonded and fixed in the installation groove 4, and the adjacent diamond agglomerates 2 are equally spaced.

[0046] A total of 28 introduction holes 7 are provided on the grinding wheel base 1, and 4 cooling holes 6 are provided on each diamond agglomerate 2. Correspondingly, 4 transition grooves 10 are provided on each diamond agglomerate 2, and each diamond agglomerate 2. Corresponding to the transition groove 10, four cooling grooves 5 are arranged below. That is to say, each diamond agglomerate 2 corresponds to two introduction holes 7 , that is, each diamond agglomerate 2 has a non-one-to-one correspondence with the introduction holes 7 , and the number of cooling holes 6 is greater than the number of introduction holes 7 .

[0047] Specifically, the four cooling groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com