Multi-stage series connection type distributed control system of robot

A control system and serial technology, applied in the direction of comprehensive factory control, manipulators, manufacturing tools, etc., can solve the problems of inability to adjust circuit boards, inconvenient installation of circuit boards, etc., and achieve the effect of being easy to fully utilize, easy to operate, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

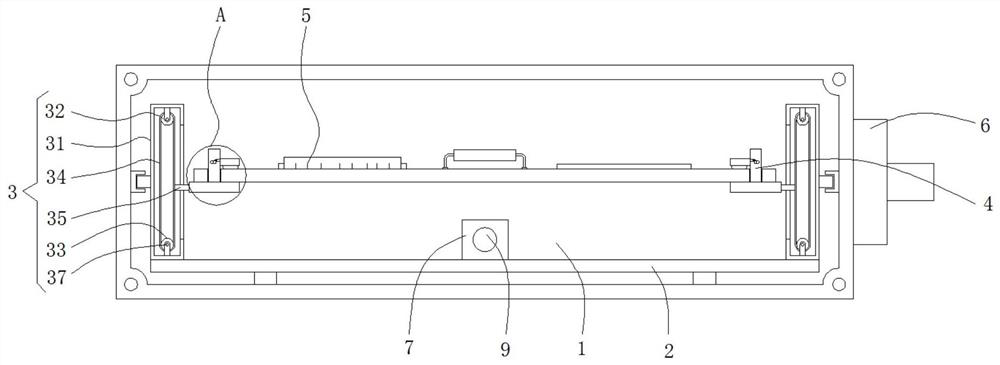

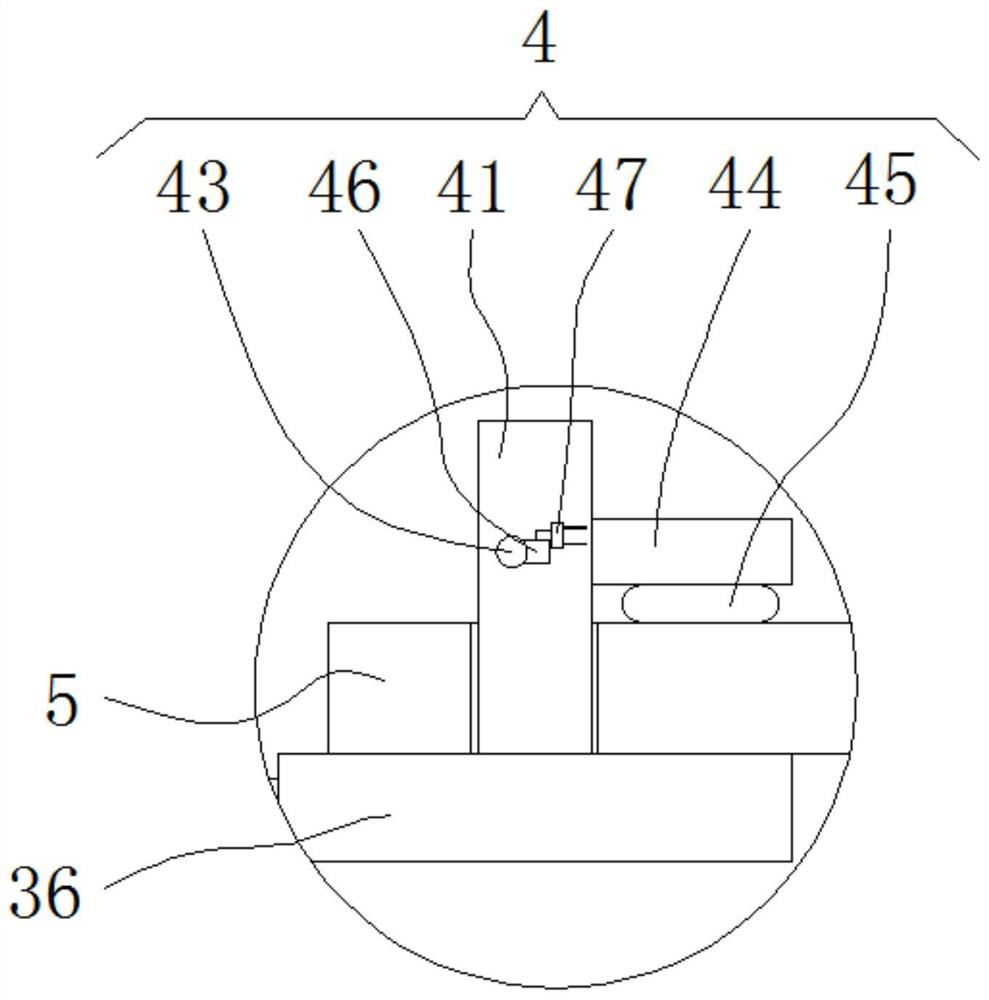

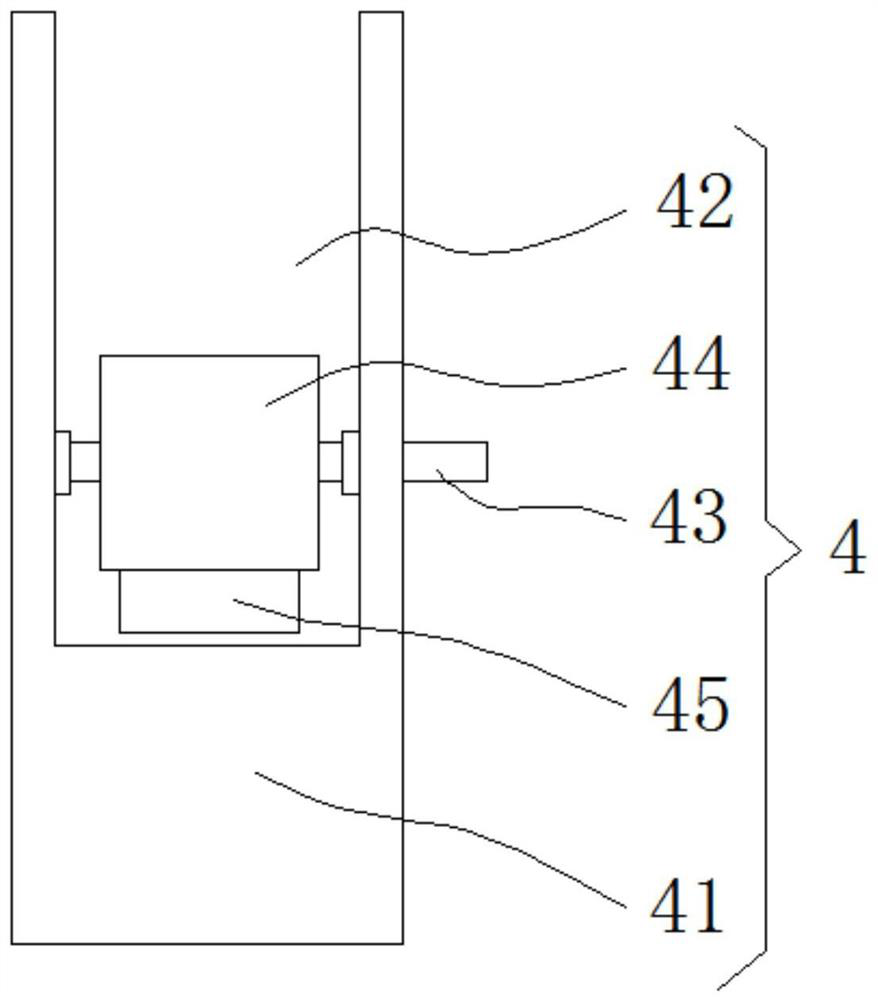

[0030] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 ,in, figure 1 A structural schematic diagram of a preferred embodiment of the robot multi-stage series distributed control system provided by the present invention; figure 2 for figure 1 shown figure 1 Partial enlarged view of A in the center; image 3 for figure 2 The structural side view of the connection block shown; Figure 4 for figure 1 The structural external view of the drive box shown; Figure 5 for figure 1 The structural exterior view of the housing shown. The multi-level series distributed control system of the robot includes:

[0031] Housing 1, the bottom of the inner wall of the housing 1 is slidably connected to a sliding plate 2, and both sides of the top of the sliding plate 2 are fixedly connected to a driving structure 3, and the two driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com