An Adaptive Clamping Tooling

A clamping tooling and self-adaptive technology, applied in the direction of chucks, manufacturing tools, metal processing equipment, etc., can solve the problems of heavy cylinder weight, large diameter, frequent replacement of clamps, etc., to reduce the chance of clamping deviation , reduce the probability of deviation, and improve the effect of transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

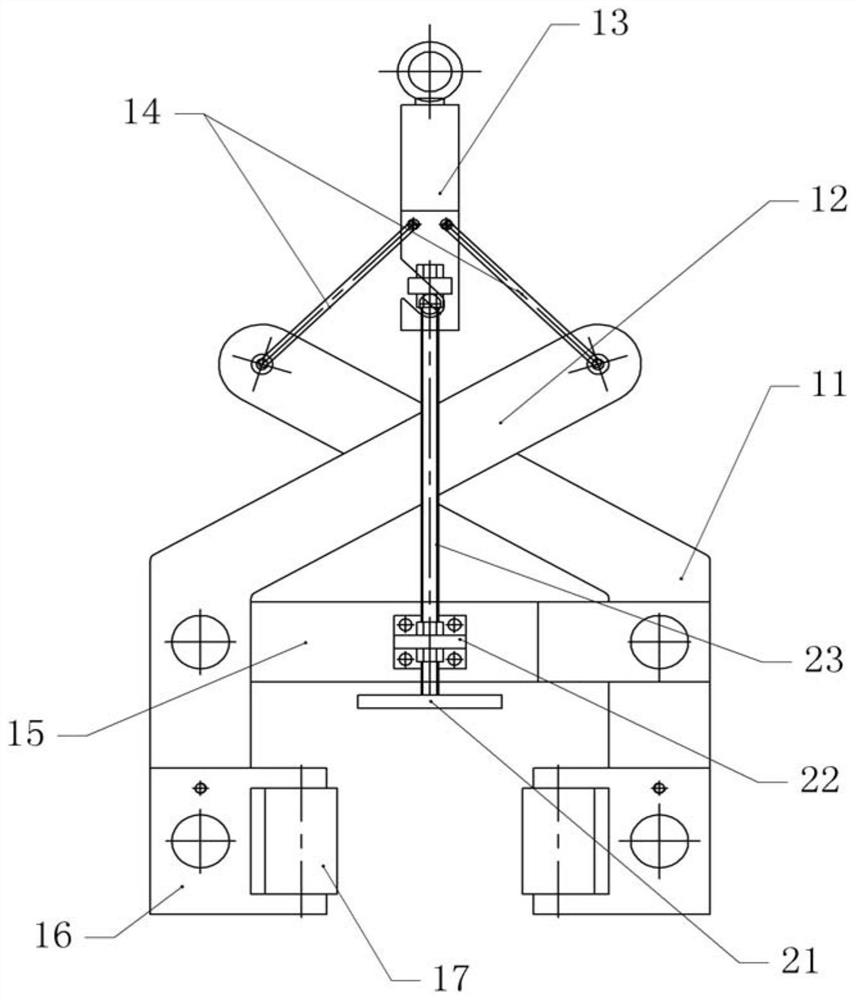

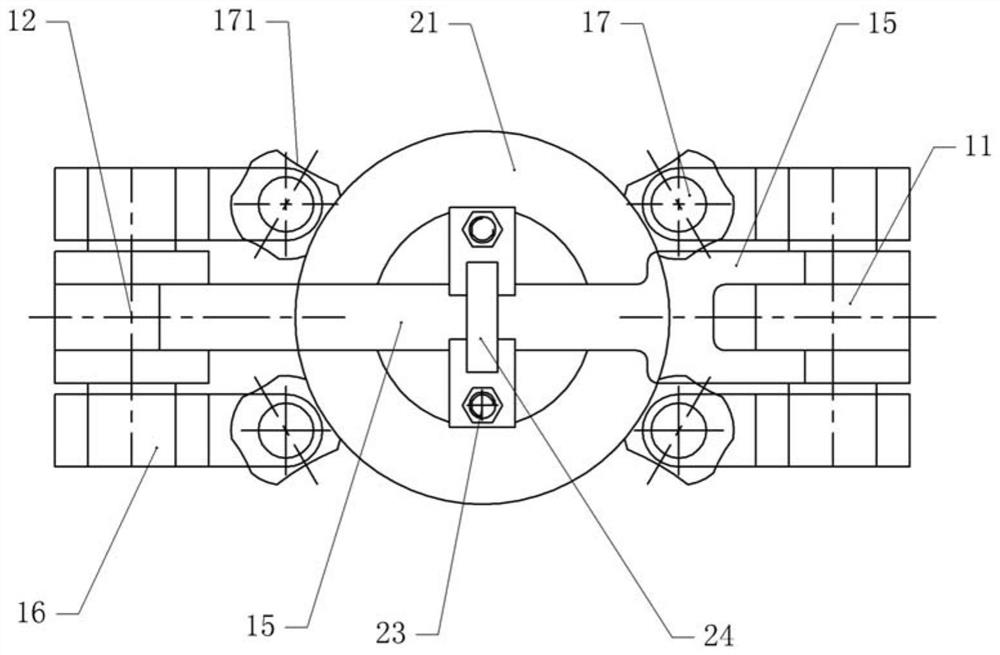

[0036] Basic as attached figure 1 To attach Figure 4 As shown: an adaptive clamping tool, including a hook 13, and a clamping body is arranged below the hook 13. In this embodiment, the clamping body includes a first clamping arm 11 and a second clamping arm 12. The first clamping arm 11 and the second clamping arm 12 are spherically hinged with a suspension rope 14 , and the suspension rope 14 is hinged with the hook 13 .

[0037] The upper crossing of the first clamping arm 11 and the second clamping arm 12 is X-shaped, and a connecting arm 15 is arranged between the first clamping arm 11 and the second clamping arm 12 bottoms, and one end of the connecting arm 15 is connected to the first clamping arm 12. The clamping arm 11 is rotatably connected, the other end of the connecting arm 15 is U-shaped, and the second clamping arm 12 is located between the other U-shaped ends of the connecting arm 15 , and the connecting arm 15 is rotatably connected to the second clamping ar...

Embodiment 2

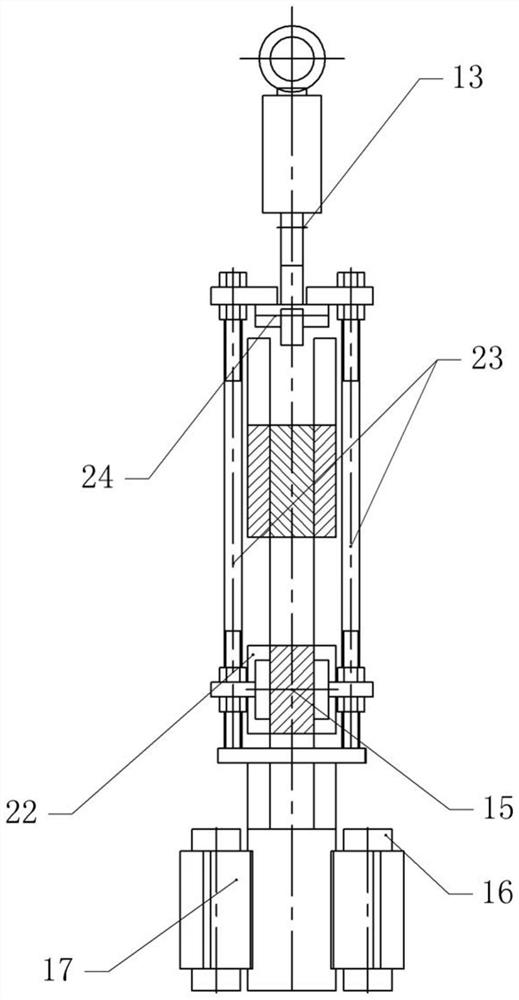

[0043] The difference between embodiment two and embodiment one is that, as attached Figure 5 And attached Image 6 As shown, the clamping member 17 includes a rotating shaft 172 and a clamping portion, and the clamping groove 171 is arranged along the circumferential direction of the clamping portion. The lower part of the rotating shaft 172 is connected to the fixed block 16 in rotation. The rotating shaft 172 is provided with several sliders 173 along its circumference. The elastic part in the example is a spring 175, one end of the spring 175 is welded on the slider 173, the other end of the spring 175 is welded on the rotating shaft 172, and the side of the slider 173 away from the spring 175 has an inclined surface. The fixed block 16 is provided with a plurality of sliding slots 174 , the number of sliding slots 174 is the same as that of the sliding blocks 173 , and the sliding blocks 173 are located in the sliding slots 174 .

[0044] The specific implementation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com