Automatic grouting system

An automatic and vacuum system technology, applied in the direction of cement mixing device, control device, batching and batching instrument, etc., can solve the problems of low degree of automation, inability to fully guarantee the compactness of grouting, inaccurate measurement of batching and grouting volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate those skilled in the art to understand the technical solution of this patent, the technical solution of this patent will be further described in the form of specific cases below.

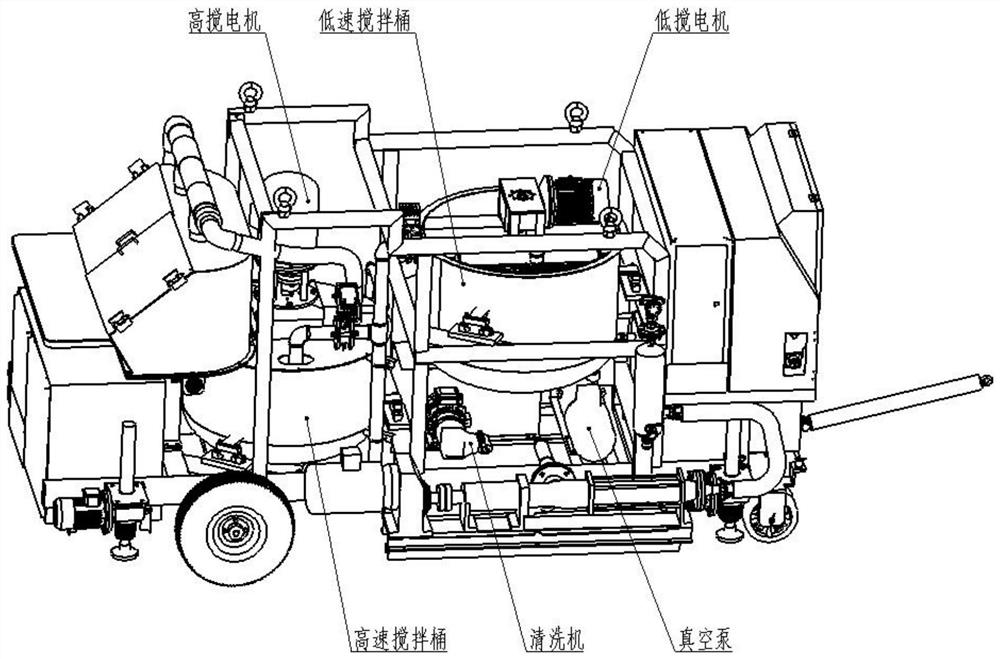

[0036] An automatic grouting system, including a pulping system, a slurry storage system, a grouting system and a vacuum system, the pulping system includes a high-speed mixing tank and a high-speed mixing motor, and the slurry storage system includes a low-speed mixing tank and a low-speed mixing motor , the grouting system includes a feeding motor and a pouring valve, and the vacuum system includes a vacuum pump. The pulping system, weighing system, pulp storage system, grouting system and vacuum system are all integrated on one grouting trolley, such as figure 1 shown.

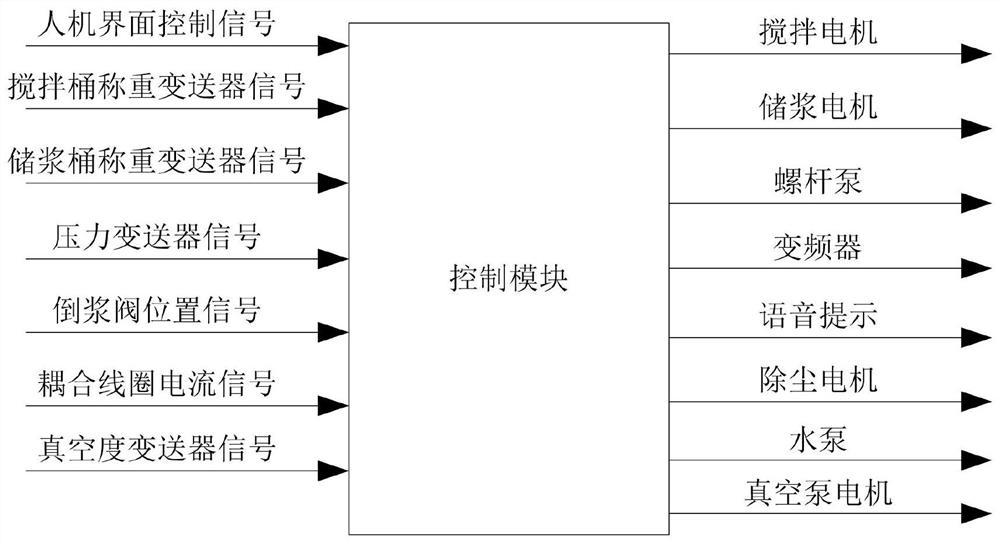

[0037] In addition, the system also includes a control module, a high-speed mixing tank weighing sensor, a high-speed mixing motor current transformer, a feeding motor current transformer, a low-spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com