Preparation method of anti-corrosion self-healing superhydrophobic material based on reversible hydrogen bond group

An anti-corrosion and self-healing technology, used in anti-corrosion coatings, cellulose coatings, polyamide coatings, etc., can solve the problems of high preparation cost, cumbersome preparation process, and reduced coating recycling ability, and achieves low cost, preparation simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

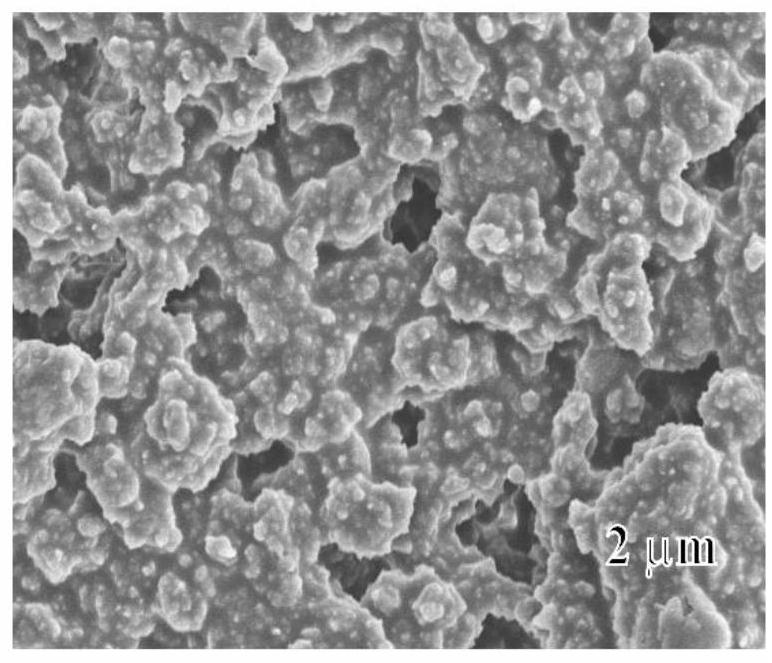

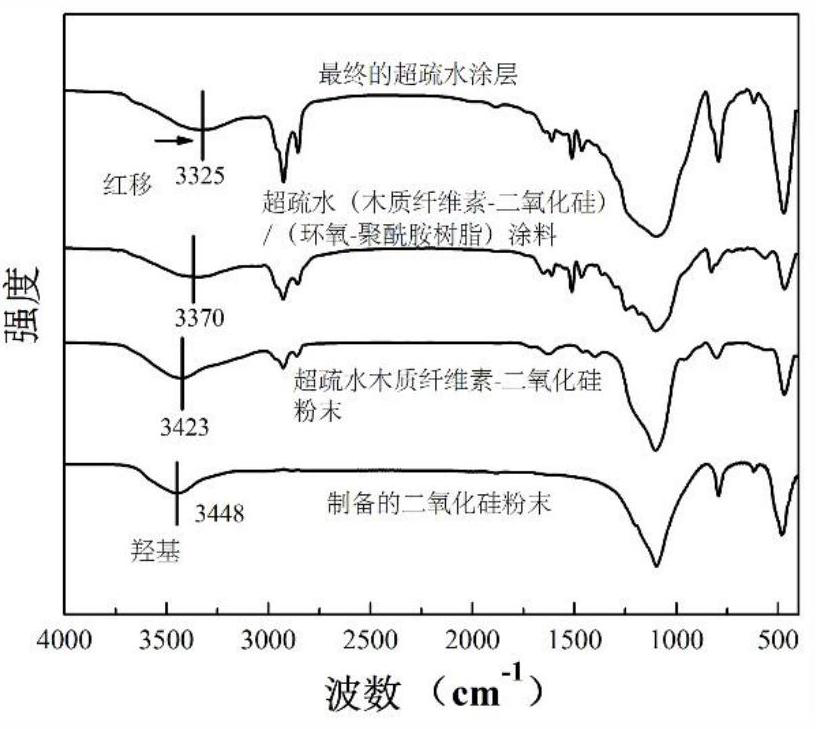

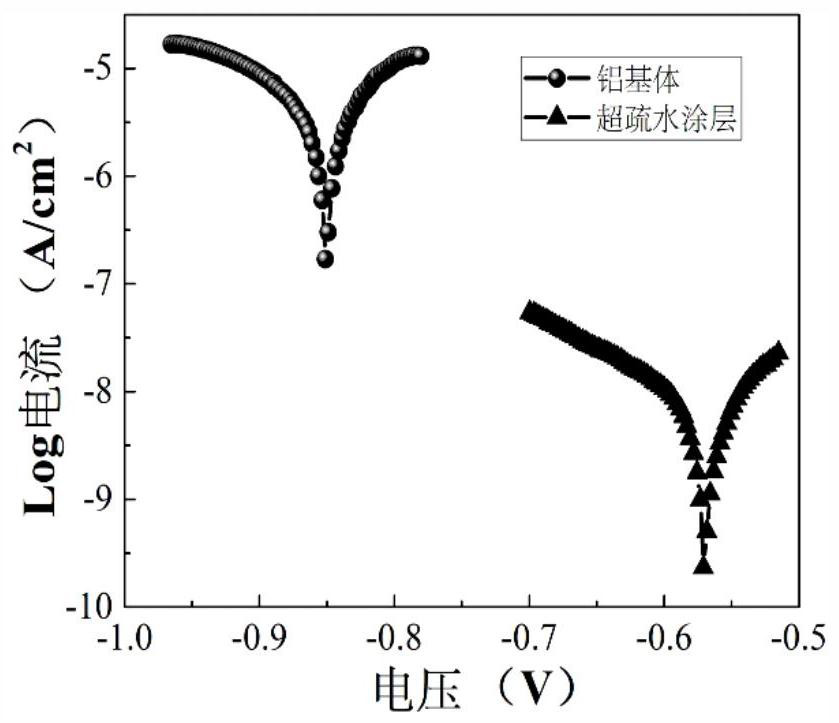

[0025] 10 ml of ammonia was added to a mixture containing 180 ml of ethanol, 20 ml of silicate and 20 ml of deionized water, stirred at room temperature for 12 hours, dried at 50 ° C to obtain silica nanoparticles, and the particle size was 35 ± 5 nm; 1 mL of octadecyclosoxysilane was added to 70 ml of ethanol containing 0.5 g of lignocellulose and 6 g of silica, and the suspension was 2 hours at 25 ° C. Ultrasound and stirring reaction, purifying the centrifugation granules was purified by ethanol, drying at room temperature, obtaining superhydrophobic micro / nanoparticles; 3 g of superhydrophilic powder added to a 3 g of epoxy resin and 2 g of a polyamide resin 80 ml of ethanol solution In seconds, ultrasonic treatment and magnetic force are stirred for 2 hours, and a uniform super-hydrophobic coating is finally obtained.

[0026] The superhydrophobic coating is applied to the metal aluminum surface by spraying, and the spray process is sprayed for 30 seconds under pressure of ...

Embodiment 2

[0030] Different from Example 1 in:

[0031] Further hydrophobic modifications were further impregnated in ethanol solution containing 0.25 wt% octadecyclosoxysilane.

[0032] After testing, the prepared coating has excellent self-healing properties, as shown in Figure 3 (a). When the coating is chemically damaged, only 10 hours of time will return to the original superhydrophobic properties at room temperature. The superhydrophobic coating prepared by this condition is still much faster than the superhydrophobic coating prepared by high temperature curing at 100 ° C for 2 hours, as shown in Fig. 3 (b), the common price key The superhydrophilic coating of the base is from about 24 hours at room temperature.

Embodiment 3

[0034] Different from Example 1 in:

[0035] The superhydrophobic coating is applied to the surface of the fiber fabric using a dipping manner, and a superhydrophilic fiber fabric having self-healing capacity is prepared by curing. Among them, the impregnation process is to complete the fiber fabric into the coating, impregnated for 1 minute.

[0036] After testing, the prepared superhydrophobic fiber fabric has excellent oil-water separation performance, and the superhydrophobic fiber fabric is subjected to oil pollution damage, and the oil separation ability is lowered; after cleaning of ethanol, at room temperature, it takes 4 hours to restore the original oil water. Separation ability, such as Figure 4 Indicated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com