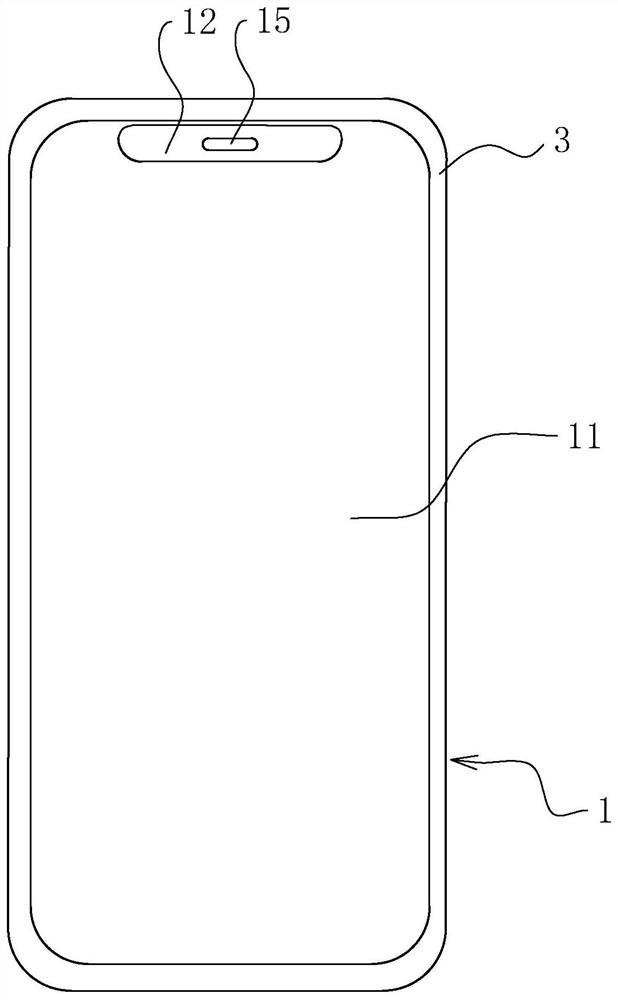

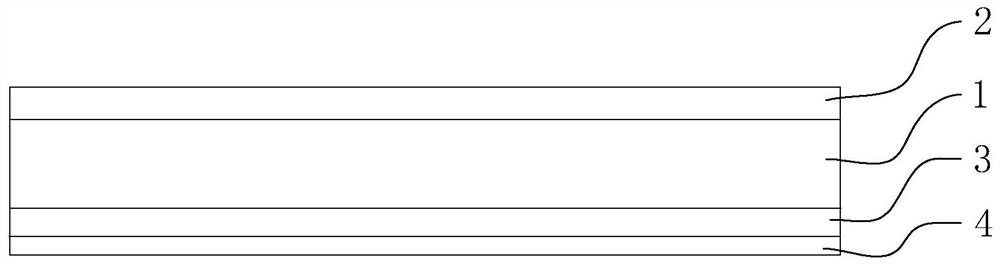

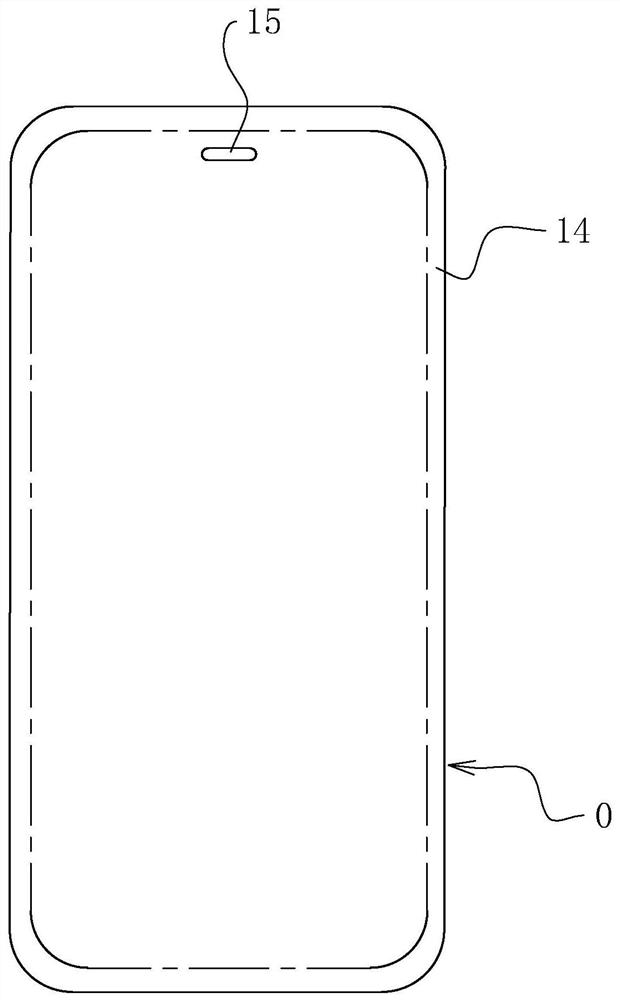

Frosted tempered film and preparation process thereof

A preparation process and tempered film technology, which is applied to branch office equipment, film/sheet adhesives, coatings, etc., can solve the problems of reduced light transmittance, inability to protect the front camera, and inability to shoot normally. Soft light, good adhesion, reduce the effect of sand falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0084] A protective oil, made by the following method:

[0085] Modified talcum powder preparation:

[0086] preprocessing. Pulverize the talcum powder by ball milling to make the particle size smaller than 120 mesh, then pickle the talcum powder with a concentration of 10% sulfuric acid solution, pickle for 30 minutes, and then wash with water to make it neutral . Then mix it with hydroxypropyl acrylate, the weight ratio of the two is 1:0.2, after stirring evenly, lower the temperature to -25°C, keep the temperature for 1.5d, and then return to room temperature, centrifuge to obtain the pretreated of talcum powder.

[0087] modified. Add titanate coupling agent to the pretreated talc powder, the weight ratio of the two is 1:0.025, add pure water, make it immersed in talc powder, soak for 15 hours, and obtain powder after centrifugation.

[0088] smash. The powder obtained in step 2 is pulverized, and the pulverization method adopts the method of ball milling, so that th...

preparation example 2

[0094] The difference from Preparation Example 1 is that the weight of each raw material is shown in Table 1. The coupling agent is silane coupling agent KH560, and the defoaming agent is polydimethylsiloxane.

[0095] During the preparation of the modified talc powder, the weight ratio of the washed talc powder to hydroxypropyl acrylate was 1:0.5, the cooling temperature was -30°C, and kept for 1 day. During the modification process, the weight ratio of talc powder to titanate coupling agent was 1:0.02, and the soaking time was 10h.

[0096] In the process of preparing the protective oil, in step 1, the temperature was raised to 50°C.

preparation example 3

[0098] The difference from Preparation Example 1 is that the weight of each raw material is shown in Table 1. The coupling agent is silane coupling agent kh550, and the defoaming agent is polyoxypropylene glyceryl ether.

[0099] During the preparation of the modified talc powder, the weight ratio of the washed talc powder to hydroxypropyl acrylate was 1:0.1, the cooling temperature was -20°C, and kept for 2 days. During the modification process, the weight ratio of talc powder to titanate coupling agent was 1:0.05, and the soaking time was 20h.

[0100] In the process of preparing the protective oil, in step 1, the temperature was raised to 80°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com