A high-performance asphalt self-adaptive laying device and method

A laying device and self-adaptive technology, applied in roads, buildings, road repair, etc., can solve the problems of heavy asphalt and devices, which are not conducive to reducing construction costs, and cannot be laid, so as to reduce construction costs, improve laying quality, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions of the present invention will be further described below with reference to the accompanying drawings and through specific embodiments.

[0050] Among them, the accompanying drawings are only used for exemplary description, and represent only schematic diagrams, not physical drawings, and should not be construed as restrictions on this patent; in order to better illustrate the embodiments of the present invention, some parts of the accompanying drawings will be omitted, Enlarged or reduced, does not represent actual product size.

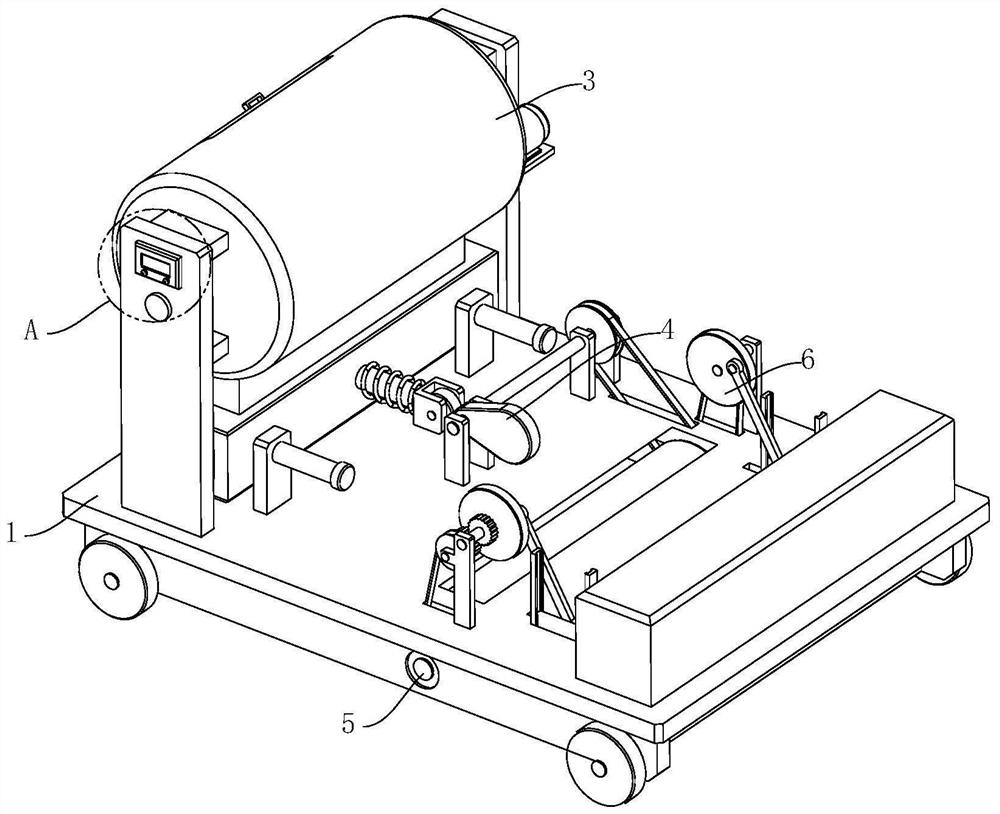

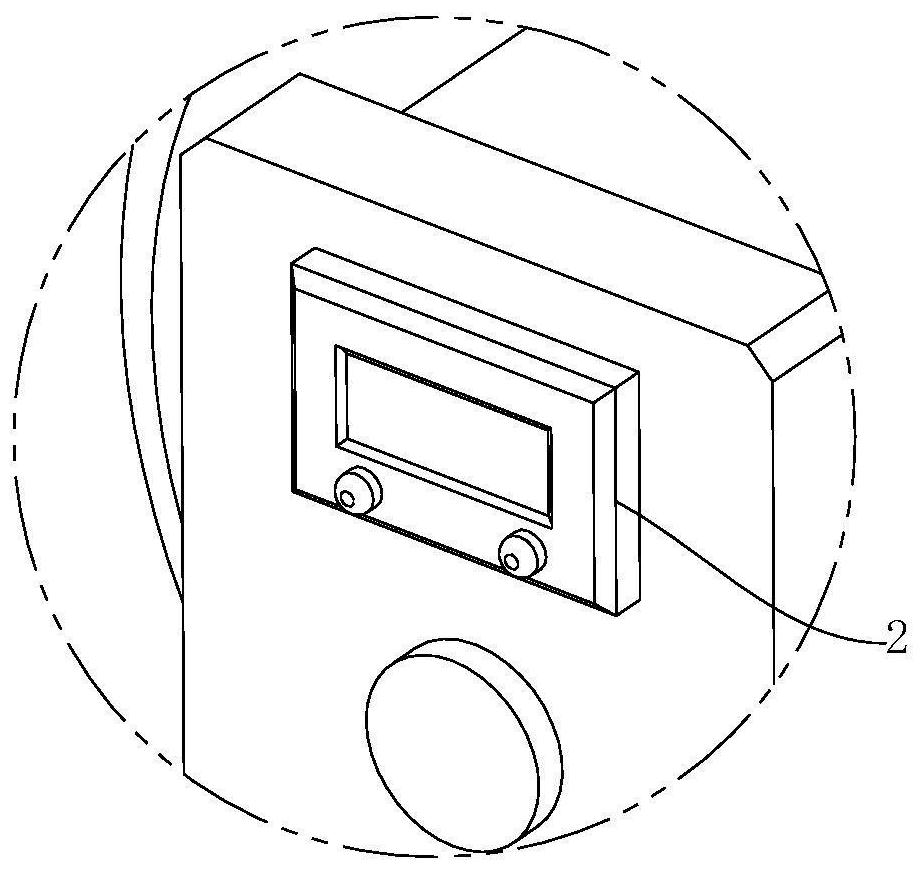

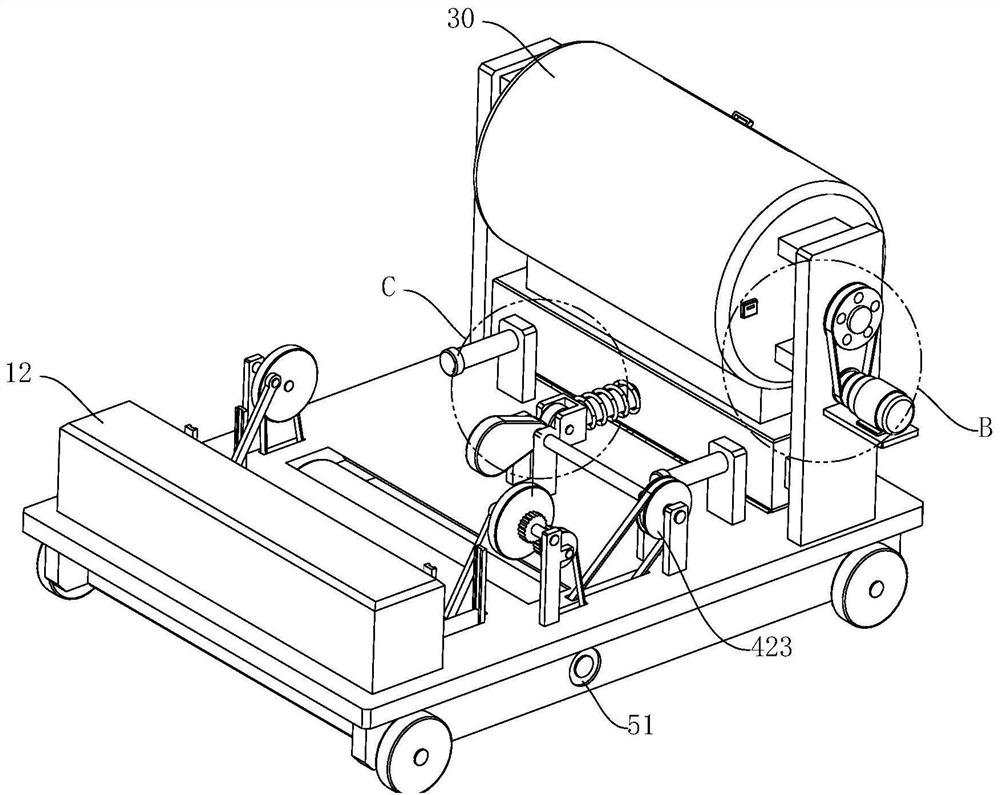

[0051] refer to Figure 1 to Figure 9 The shown high-performance asphalt self-adaptive laying device includes an electric trolley 1, a controller 2, a stirring mechanism 3, a pushing mechanism 4, a rolling mechanism 5 and a trimming mechanism 6, and the stirring mechanism 3 is located in the The top of the electric trolley 1 is used to mix asphalt. The stirring mechanism 3 includes a heating kettle 30, a driving motor ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap