Anti-floating bag type positioning grouting anchor rod for underwater tunnel and construction method of anti-floating bag type positioning grouting anchor rod

A technology of grouting bolts and underwater tunnels, which is applied to the installation of bolts, earthwork drilling, mining equipment, etc., and can solve problems such as inability to accurately and timely prevent tunnel uplift, improper control of surcharge pressure, and tunnel convergence damage. Achieve the effect of fast and convenient construction, increased weight and large grouting space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

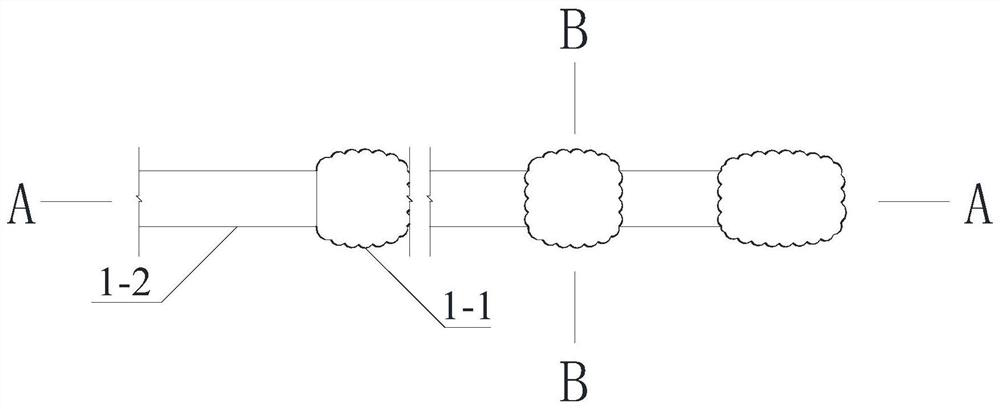

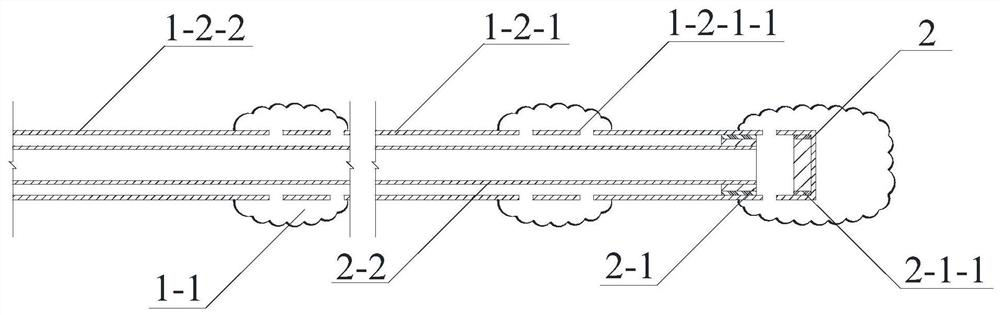

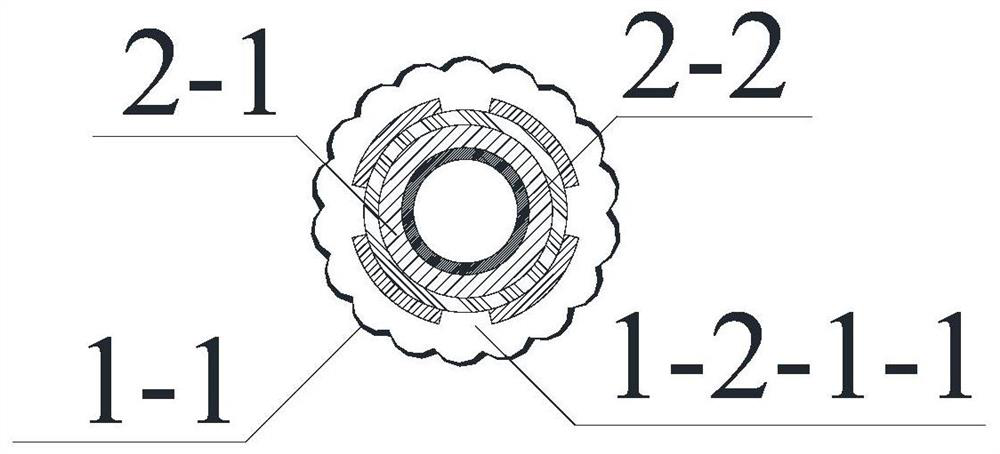

[0056] Such as Figure 1-4 As shown, this embodiment provides a bladder-type positioning grouting anchor for anti-floating of underwater tunnels, including a bladder-type positioning grouting anchor foundation body 1 and a positioning grouting device 2;

[0057] The base body 1 of the capsule positioning grouting anchor includes a bladder 1-1, a perforated tube 1-2 and a pressure sensor; the perforated tube 1-2 is sealed from bottom to top, and the perforated grouting section 1-2-1 and the non-porous section 1-2-2 for installation; several groups of grouting holes 1-2-1-1 are set on the perforated grouting section 1-2-1 of the perforated pipe 1-2 , a group of grouting holes 1-2-1-1 is arranged at the bottom seal, and the outer side of each group of grouting holes 1-2-1-1 is connected with a pouch 1-1 by steel bars, and each group of grouting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com