Testing method and device for performance of hot melt adhesive layer of lithium ion battery and lithium ion battery

A lithium-ion battery and hot-melt adhesive layer technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of strong subjectivity and the inability to provide effective data for hot-melt adhesive layer design, and achieve low execution difficulty, The effect of large industrial application value and high data reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

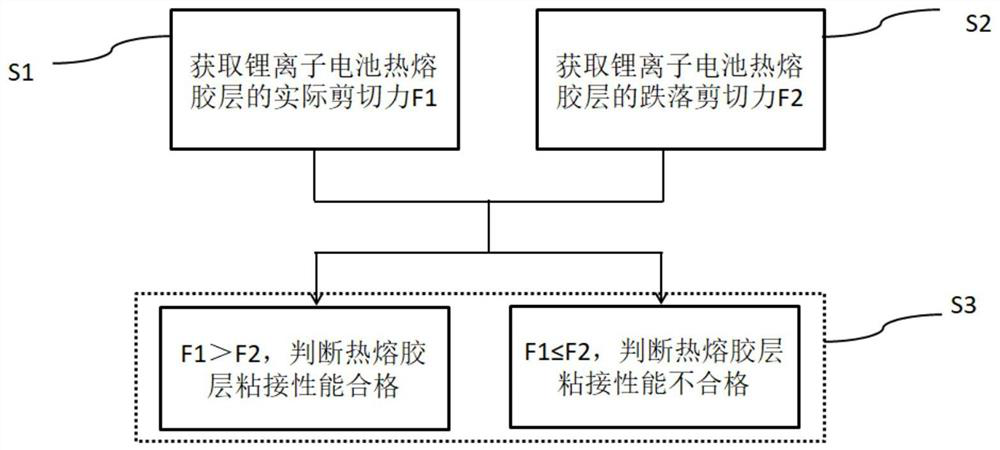

[0168] The actual shear force F1 of obtaining the lithium-ion battery hot melt adhesive layer of the present embodiment specifically includes the following steps:

[0169] 1. Prepare 3 lithium-ion battery samples of type A and make them into actual shear force test samples of the hot-melt adhesive layer of lithium-ion batteries;

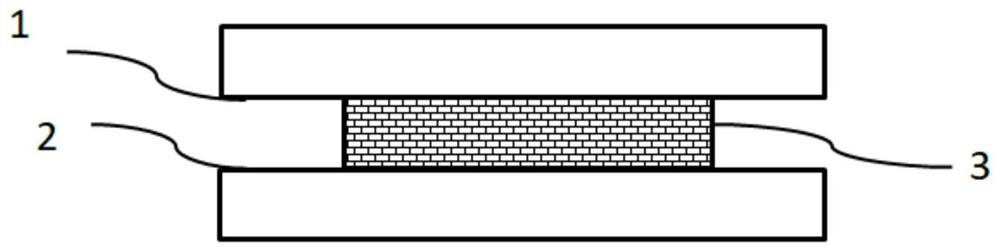

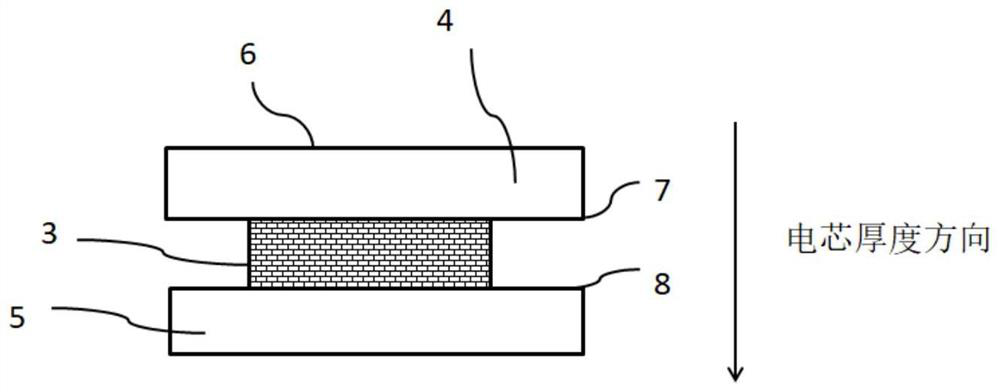

[0170] Among them, the cell mass of type A lithium-ion battery is 0.082kg, and the area S1 of the hot melt adhesive layer is 720mm 2 , the first inner surface of the lithium-ion battery packaging layer is connected to the first surface of the battery cell through a hot melt adhesive layer, and the first outer surface is opposite to the first inner surface;

[0171] 2. Use the upper clamp of the tensile machine to clamp the clamping end of the packaging layer of the actual shear force test sample of the hot melt adhesive layer of the lithium-ion battery to be tested, and the lower clamp to clamp the clamping end of the battery cell;

[0172] 3. Set t...

Embodiment 2

[0179] The operation steps for obtaining F1 in this embodiment 2 are basically the same as the operation steps for obtaining F1 in embodiment 1. The only difference is that in this embodiment 2, a type B lithium-ion battery is used, the battery cell mass is 0.075kg, and the hot melt adhesive layer Area S1 is 900mm 2 , measured F1 = 108.5N;

[0180] The operation steps of obtaining F2 in the second embodiment are the same as those in the first embodiment, and the measured F2=82.08N.

Embodiment 3

[0182] The operation steps of this embodiment 3 are basically the same as that of embodiment 1, the only difference is that in this embodiment 3 a type C lithium-ion battery is used, the mass of the battery cell is 0.065kg, and the area S1 of the hot melt adhesive layer is 840mm 2 , measured F1 = 67.7N;

[0183] The operation steps for obtaining F2 in Embodiment 3 are consistent with the operation steps for obtaining F2 in Embodiment 1, and it is measured that F2=71.14N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com