Based on ti 3 c 2 High sensitivity lrspr fiber optic sensor and its preparation method

A fiber-optic sensing and high-sensitivity technology, applied in the field of sensors, can solve the problems of low sensitivity of LRSPR sensors, achieve a good electron transfer rate, improve sensitivity, and increase the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In this embodiment, a Ti-based 3 C 2 High-sensitivity LRSPR fiber optic sensor, and use this sensor to detect solutions with different refractive indices.

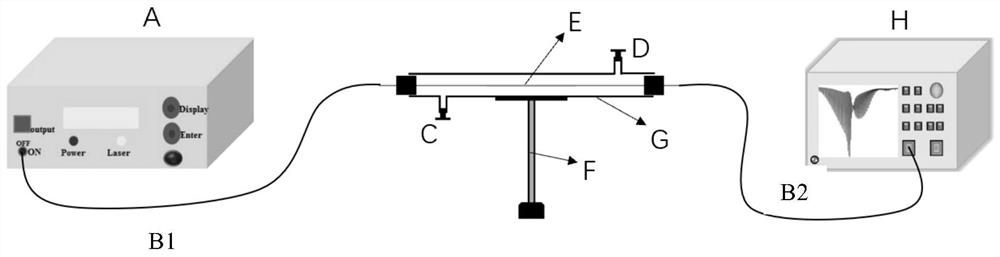

[0055] A Ti-based 3 C 2 The high-sensitivity LRSPR fiber optic sensor, its structure schematic diagram is as follows figure 2 shown, including Ti-based 3 C 2 High-sensitivity LRSPR optical fiber sensing unit E, light source A, spectrometer H;

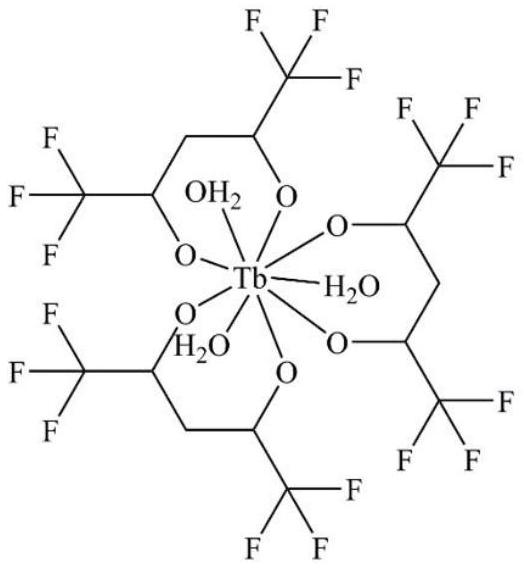

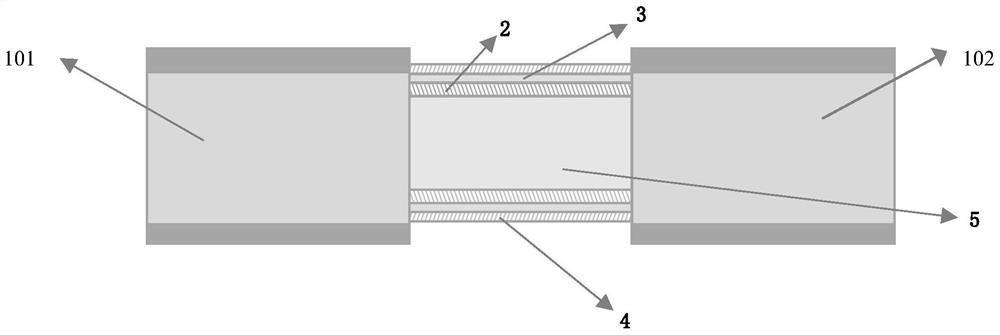

[0056] A Ti-based 3 C 2 The high-sensitivity LRSPR optical fiber sensing unit comprises a single-mode optical fiber core 5 and a multimode optical fiber, the multimode optical fiber is divided into a first multimode optical fiber 101 and a second multimode optical fiber 102, one end of the first multimode optical fiber 101 and a single-mode optical fiber One end of the mode fiber core 5 is connected, the other end of the single-mode fiber core 5 is connected to one end of the second multimode fiber 102, and on the periphery of the single-mode fiber core 5, terbium (I...

Embodiment 2

[0077] A Ti-based 3 C 2 The high-sensitivity LRSPR optical fiber sensor, with embodiment 1.

[0078] A Ti-based 3 C 2 The preparation method of the high-sensitivity LRSPR optical fiber sensing unit, comprises the following steps:

[0079] Step 1: First take two multimode optical fibers with a length of 20 cm, respectively as the first multimode optical fiber 101 and the second multimode optical fiber 102, and remove 2-3 cm of one end of the first multimode optical fiber 101 and the second multimode optical fiber 102 respectively Then take a single-mode optical fiber with a length of 2 cm and remove the cladding to obtain a single-mode optical fiber core with a refractive index of 1.4660 and a core diameter of 8 μm. Then, the ends of the two multimode optical fibers from which the coating has been removed are fused to the cores of the single-mode optical fibers respectively.

[0080] Step 2: Coating a layer of 150nm terbium(III) fluorine-containing complex matching layer on ...

Embodiment 3

[0091] A Ti-based 3 C 2 The high-sensitivity LRSPR optical fiber sensor of the present invention is the same as embodiment 1, except that the thickness of each layer is different, and the metal layer is a silver film.

[0092] A Ti-based 3 C 2 The preparation method of the high-sensitivity LRSPR optical fiber sensing unit, comprises the following steps:

[0093] Step 1: First take two multimode optical fibers with a length of 20 cm, respectively as the first multimode optical fiber 101 and the second multimode optical fiber 102, and remove 2-3 cm of one end of the first multimode optical fiber 101 and the second multimode optical fiber 102 respectively Then take a single-mode optical fiber with a length of 2 cm and remove the cladding to obtain a single-mode optical fiber core with a refractive index of 1.4660 and a core diameter of 10 μm. Then, the ends of the two multimode optical fibers from which the coating has been removed are fused to the cores of the single-mode op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com