Parallel pipeline non-contact harmonic magnetic field diagnosis method and indoor experiment system

A harmonic magnetic field and experimental system technology, applied in the direction of material magnetic variables, etc., can solve problems such as poor anti-interference ability, complicated operation, and bulky instruments, and achieve the effect of high magnetic field strength, high sensitivity, and enhanced advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

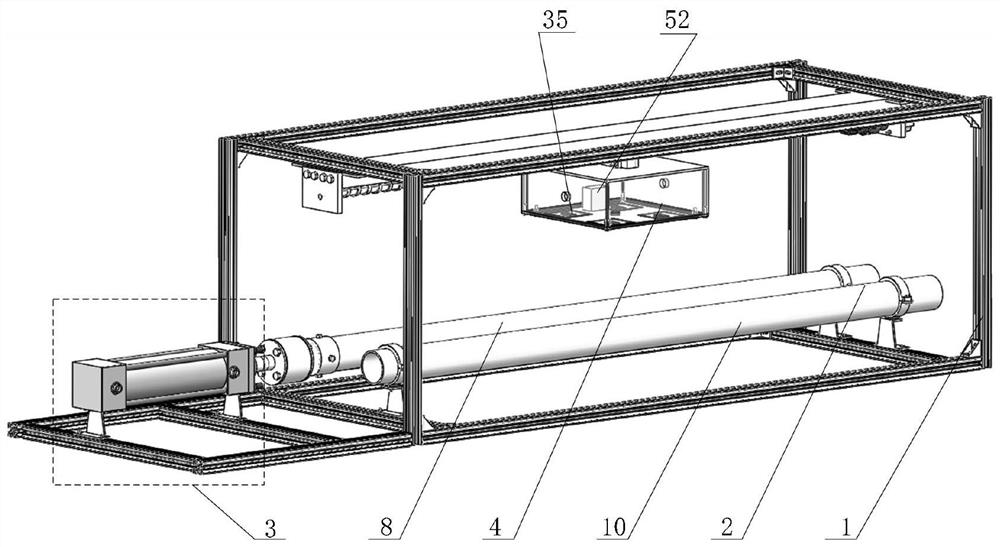

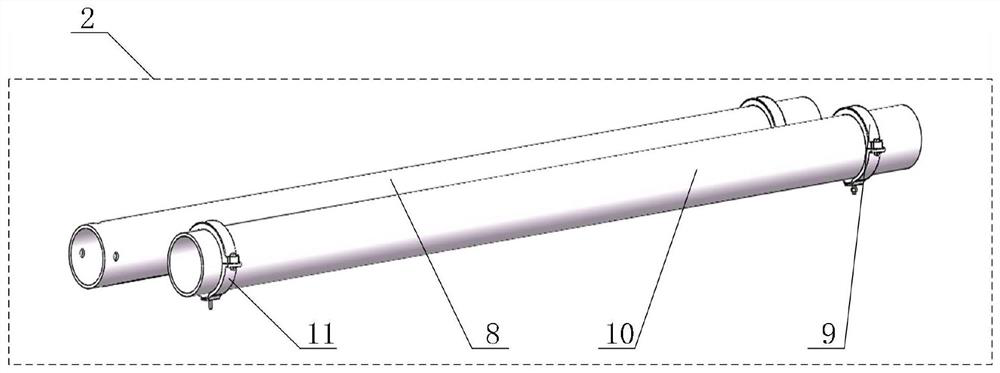

[0036] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings. like figure 1 As shown in the overall structure diagram, a parallel pipeline non-contact harmonic magnetic field diagnosis method and an indoor experimental system provided by the present invention include an experimental system frame (1), a parallel pipeline system (2), a loading module (3) and a detection module ( 4).

[0037] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

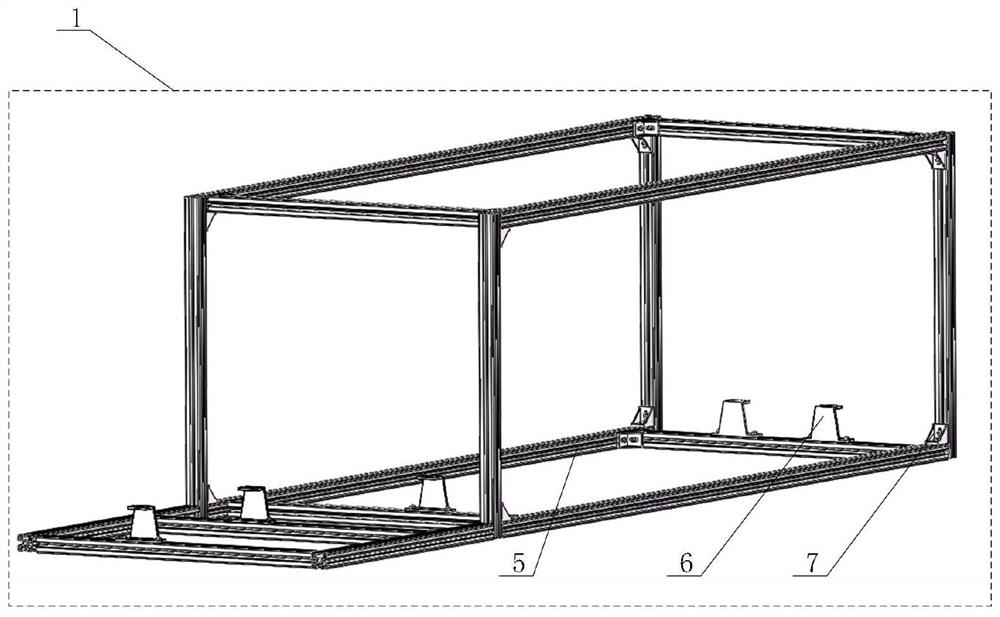

[0038] figure 2 It is a structural schematic diagram of the experimental system frame (1) of the present invention, the experimental system frame (1) is made up of mounting bracket (5), pipeline sliding bracket (6) and corner piece (7), and is used for installing parallel pipeline system (2), Detect the guide rail platform (16) and the single-rod piston double-acting hydraulic cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com