Apparatus and method for studying the influence of alkali metals on coke reactivity under the condition of water vapor and carbon dioxide

An alkali metal and reactivity technology, which is applied in the field of devices for studying the influence of alkali metal on coke reactivity under the condition of water vapor and carbon dioxide, can solve problems such as the influence of coke reactivity, improve measurement accuracy, and make up for the inability to accurately measure alkali metal. Affect the problem of coke reaction and avoid the effect of uneven local reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0035] The experimental methods in the following examples are conventional methods unless otherwise specified. The test materials used in the following examples, unless otherwise specified, were purchased from conventional reagent stores. In the quantitative experiments in the following examples, three repeated experiments were set up, and the data were the mean value or mean ± standard deviation of the three repeated experiments.

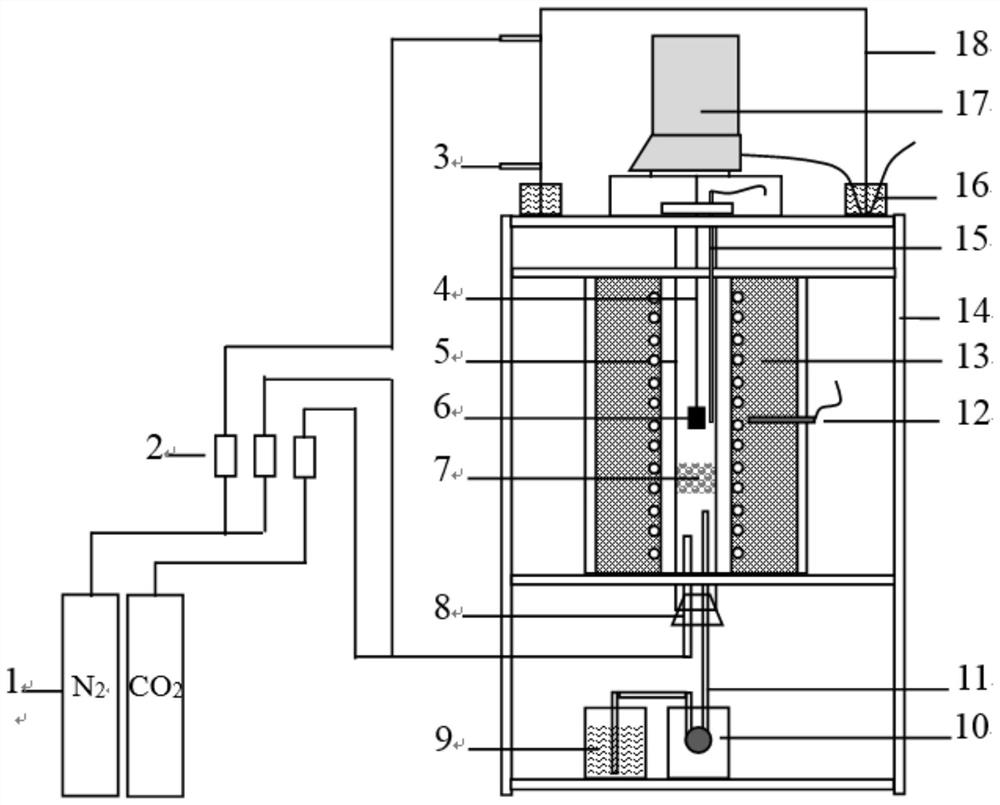

[0036] The present invention provides a device for studying the influence of alkali metals on coke reactivity, such as figure 1 Shown, including gas control system, water vapor genera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com