Natural gas gathering and transportation pipeline leakage simulation device and method

A technology of pipeline leakage and simulation device, applied in the field of leakage simulation device of natural gas gathering and transportation pipeline, can solve the problems of inability to monitor three-dimensional temperature field and toxic gas diffusion field, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

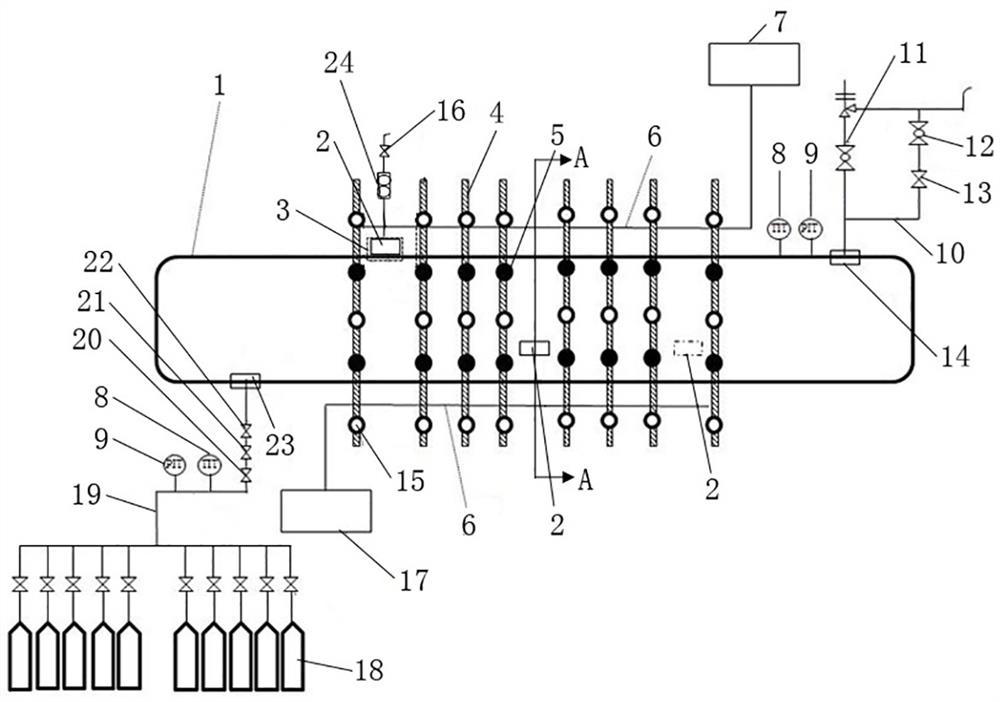

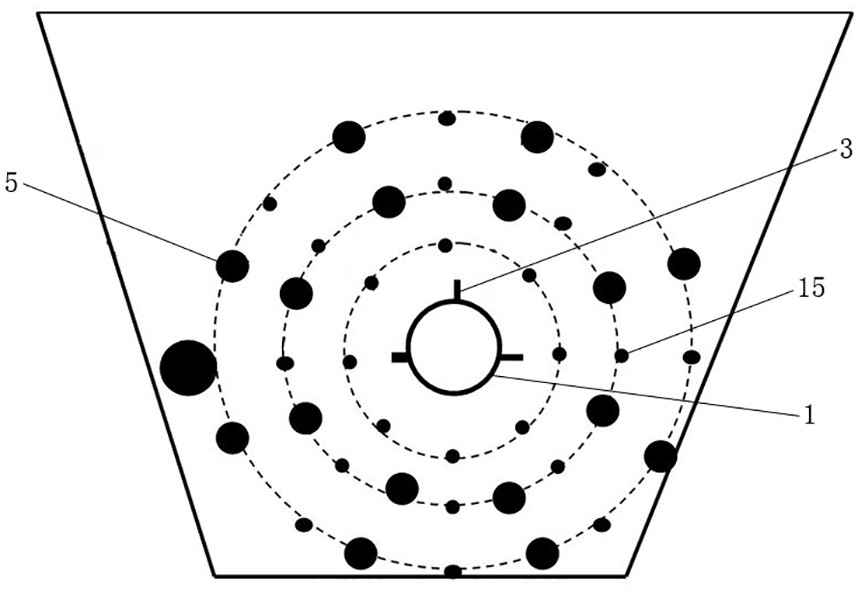

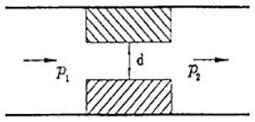

[0025] Such as Figure 1 to Figure 3 As shown, it includes simulated pipeline 1, gas supply system and venting system. The simulated pipeline 1 adopts the closed pipe section with the same material as the gathering and transportation pipeline under the actual working conditions to increase the consistency between the simulated test and the field working conditions and the accuracy of the test results. credibility. One end of the simulated pipeline 1 is provided with an air inlet 23, and the other end is provided with an air outlet 14, and the air supply system is connected with the air inlet 23 for supplying air to the simulated pipeline 1; the air vent system is connected with the air outlet 14 for After the simulation test is over, the gas in the simulation pipeline 1 is quickly released. Three groups of leakage holes 2 are arranged at intervals along the axial direction on the side wall of the simulated pipeline 1 , the distance between two adjacent groups of leakage holes...

Embodiment 1

[0078]The natural gas gathering and transportation pipeline in Example 1 is a buried pipeline, and the natural gas gathering and transportation pipeline in this example is a spanning pipeline. The layout of the simulation test site for the spanning pipeline will be described in detail below. It should be noted that the simulation device used in this example is the same as that in Example 1.

[0079] The layout of the simulated test site for the spanning pipeline:

[0080] (1) Leaping pipeline layout

[0081] Determine the specific location of the on-site experiment point for the leaping pipeline leakage monitoring, and carry out the leaping simulated pipeline layout in the high-sulfur gas field according to the safety distance of the pipeline layout and the relevant requirements for environmental impact. Arrange the high-pressure gas cylinders in the test area according to the site requirements, connect the gas supply pipeline with the high-pressure gas cylinders, connect the...

specific Embodiment 3

[0091] In the above embodiment, the temperature sensor and the concentration sensor are arranged on the mounting bracket at the same time, which can simultaneously monitor the temperature change and the concentration change of the toxic gas near the leakage hole. In this embodiment, the sensors are changed for the following two situations: if it is only necessary to monitor the temperature change near the leakage hole, only the temperature sensor may be arranged. Similarly, if it is only necessary to monitor changes in the concentration of toxic gases near the leak hole, only concentration sensors may be deployed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com