Fresh turnover material delivery task generation method and device

A generation device and turnover technology, applied in the direction of resources, logistics, instruments, etc., can solve the problems of difficult volume of fresh commodities, tight time, and difficulty in determining the quantity of outbound materials, achieving broad market application prospects, easy to popularize and use, The effect of facilitating data traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

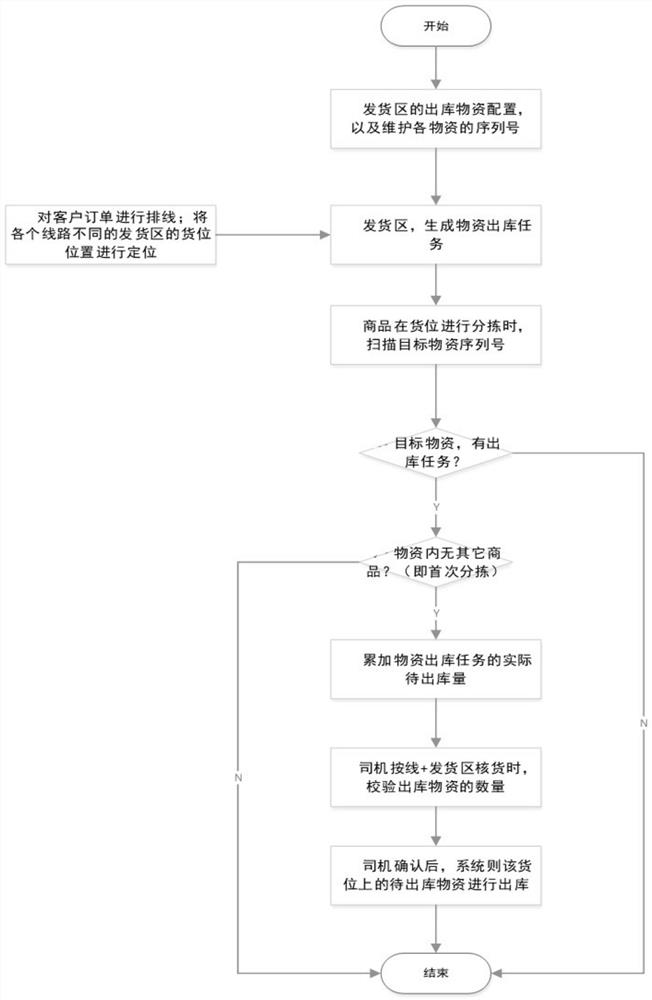

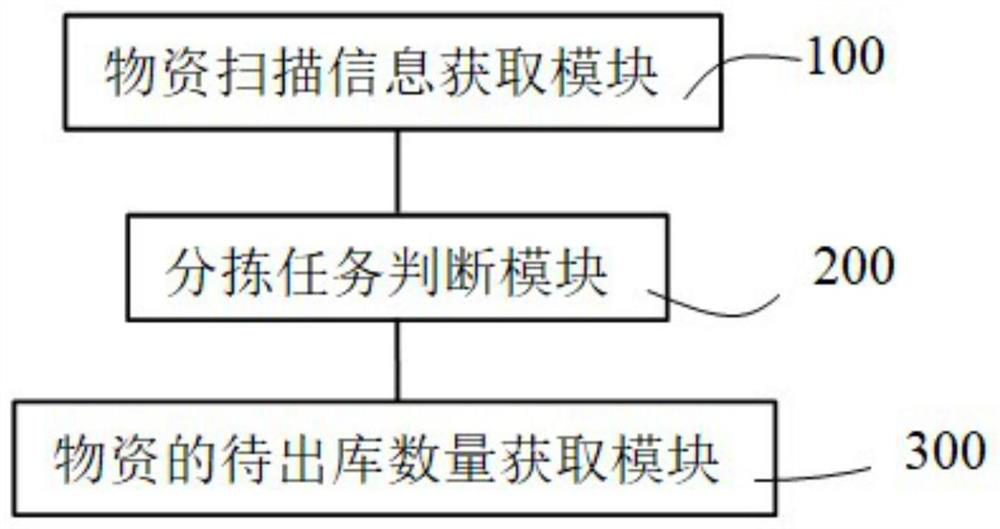

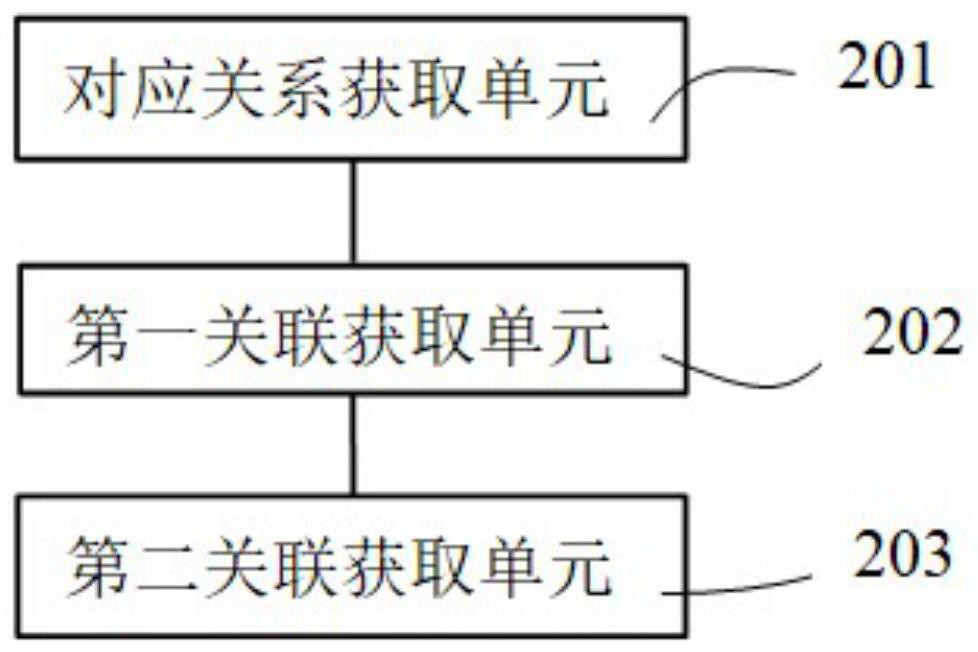

Method used

Image

Examples

Embodiment 1

[0049] Obtain the relationship C between the goods at the delivery location under each line and the serial numbers of all materials at the delivery location by the following methods:

[0050] S201. First, carry out the configuration information of the outbound materials in each delivery area, see Table 1:

[0051] Table 1

[0052]

[0053] And serial number the different materials under the same material code in the outbound material configuration information, and obtain the corresponding relationship A between the serial number of the material in each delivery area and the material code, see Table 2:

[0054] Table 2

[0055]

[0056] S202. Obtain the customer's order, arrange the order, locate the location of the delivery area of each line, and obtain the relationship B between the delivery location in each line and the goods included in the corresponding order, see Table 3:

[0057] table 3

[0058]

[0059] S203. According to the correspondence relationship A ...

Embodiment 2

[0086] Obtain the relationship C between the goods at the delivery location under each line and the serial numbers of all materials at the delivery location by the following methods:

[0087] S201. First, carry out the configuration information of the outbound materials in each delivery area, see Table 6:

[0088] Table 6

[0089]

[0090] And serial number the different materials under the same material code in the outbound material configuration information, and obtain the corresponding relationship A between the serial number of the material in each delivery area and the material code, see Table 7:

[0091] Table 7

[0092]

[0093]

[0094] S202. Obtain the customer's order, arrange the order, locate the location of the delivery area of each line, and obtain the relationship B between the delivery location in each line and the goods included in the corresponding order, see Table 8:

[0095] Table 8

[0096]

[0097] S203. According to the correspondence r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com