Back surface structure of solar cell and solar cell comprising back surface structure

A solar cell and back structure technology, applied in the field of solar cells, can solve the problems affecting the performance index of solar cells, difficult to achieve higher field passivation and H passivation requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

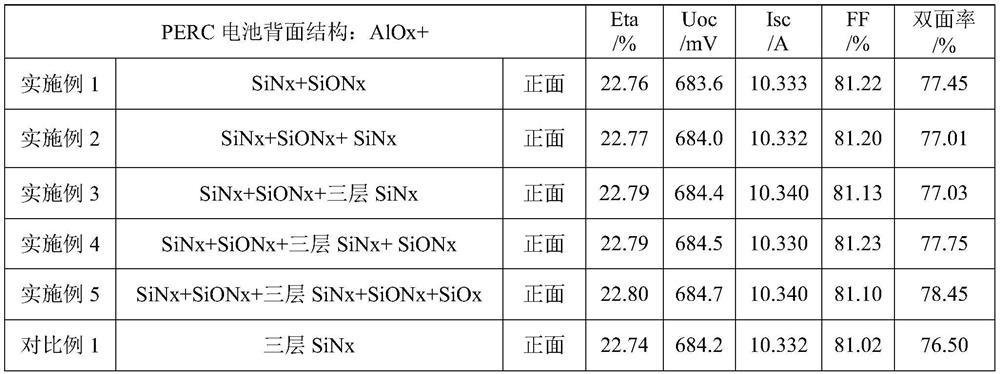

Examples

Embodiment 1

[0022] A back structure of a solar cell, comprising a silicon substrate, on the back of the silicon substrate, an aluminum oxide film layer is first deposited, and then a first silicon nitride film layer and a first silicon oxynitride film layer are sequentially deposited, wherein the first The refractive index of a silicon nitride film layer is greater than that of the first silicon nitride oxide film layer, the refractive index of the first silicon nitride film layer is 2.35, and the film thickness is 33nm; the refractive index of the first silicon nitride oxide film layer is 2.0, and the film thickness 45nm.

Embodiment 2

[0024] A backside structure of a solar cell, comprising a silicon substrate, differs from Example 1 in that a second silicon nitride film layer is also deposited on the first silicon nitride oxide film layer; the second silicon nitride film layer The refractive index of the first silicon nitride oxide film layer is smaller than that of the first silicon nitride film layer; the refractive index of the first silicon nitride film layer is 2.35, and the film thickness is 33nm; the refractive index of the first silicon nitride oxide film layer is 1.8 , the film thickness is 20nm, the refractive index of the second silicon nitride layer is 1.9, and the film thickness is 38nm.

Embodiment 3

[0026] A back structure of a solar cell, comprising a silicon substrate, differs from Embodiment 1 in that,

[0027] A second silicon nitride film layer is also deposited on the first silicon nitride oxide film layer. The second silicon nitride film layer is composed of three sub-layer silicon nitride film layers, and the aluminum oxide film layer points to the first silicon nitride film layer. The direction of the film layer from the inside to the outside is the first sub-silicon nitride film layer, the second sub-silicon nitride film layer, and the third sub-silicon nitride film layer; wherein, the refractive index of the second silicon nitride film layer is greater than that of the first sub-silicon nitride film layer A silicon nitride oxide film layer is smaller than the first silicon nitride film layer, and the refractive index of each film layer in the second silicon nitride film layer decreases sequentially from inside to outside.

[0028] The refractive index and thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com