Linear motor with axis

A linear motor and motor technology, applied in the field of linear motors and linear motors with shafts, can solve problems such as reduced vibration, friction noise, and poor roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

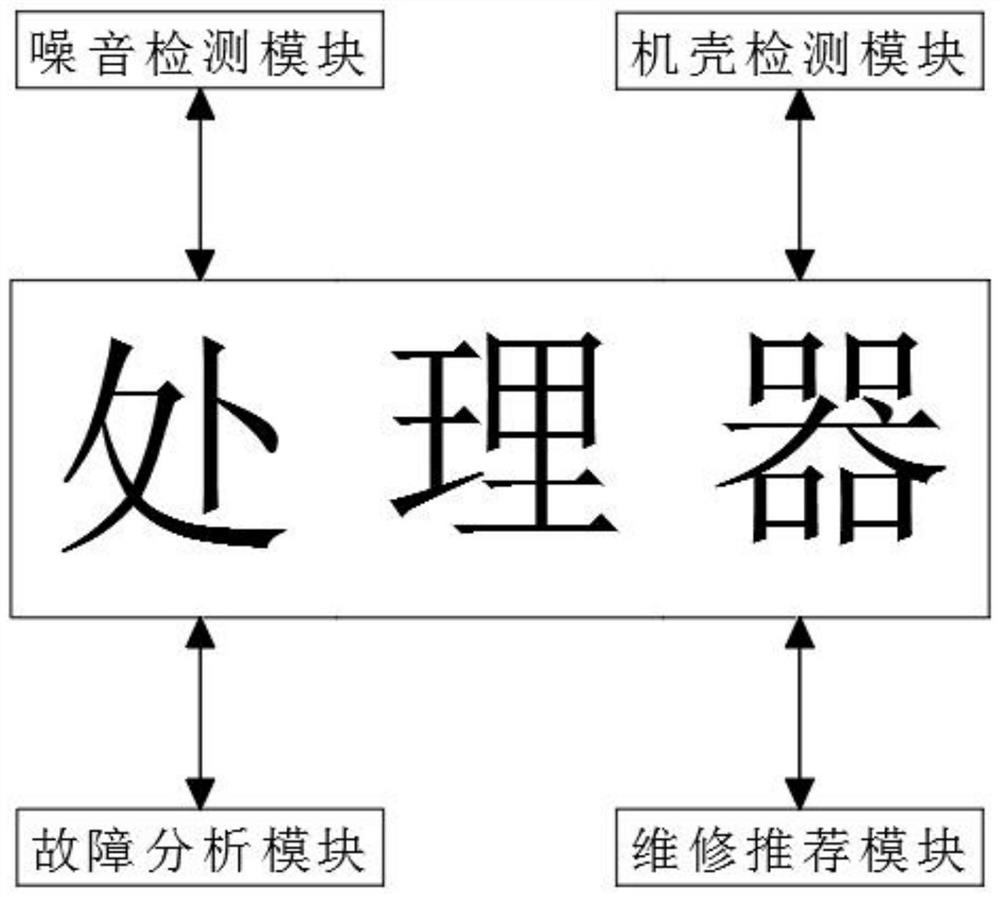

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

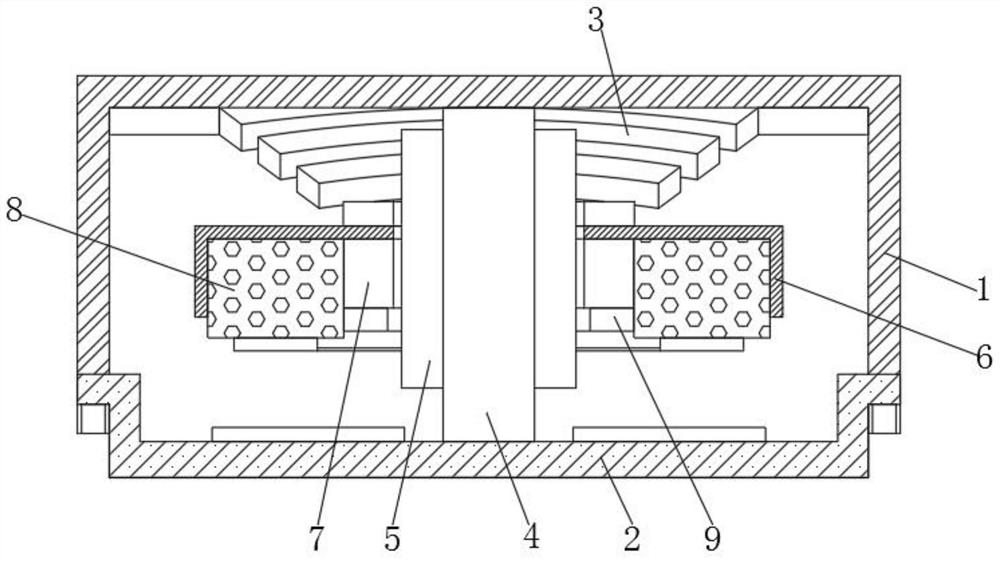

[0056] Such as Figure 1-2 As shown, a linear motor with a shaft includes an upper casing 1 and a lower casing 2, a spring 3 is fixedly installed on the inner top wall of the upper casing 1, and the lower casing 2 is located directly below the upper casing 1 , a bobbin 4 is arranged between the upper casing 1 and the lower casing 2, and the bobbin 4 is fixed on the lower casing 2 to provide support for the upper casing 1, thereby providing support for the upper casing 1 and avoiding the upper casing The shell 1 is deformed, so as to prevent the change of the resonance frequency caused by the deformation of the upper shell 1 and the friction noise due to the contact between the components, and fundamentally prevent the defects caused by the deformation of the upper shell 1, said The outer surface of the bobbin 4 is wound with an electromagnetic coil 5, and an outer locking block 6 is arranged between the upper casing 1 and the lower casing 2, and the outer locking block 6 is a ...

Embodiment 2

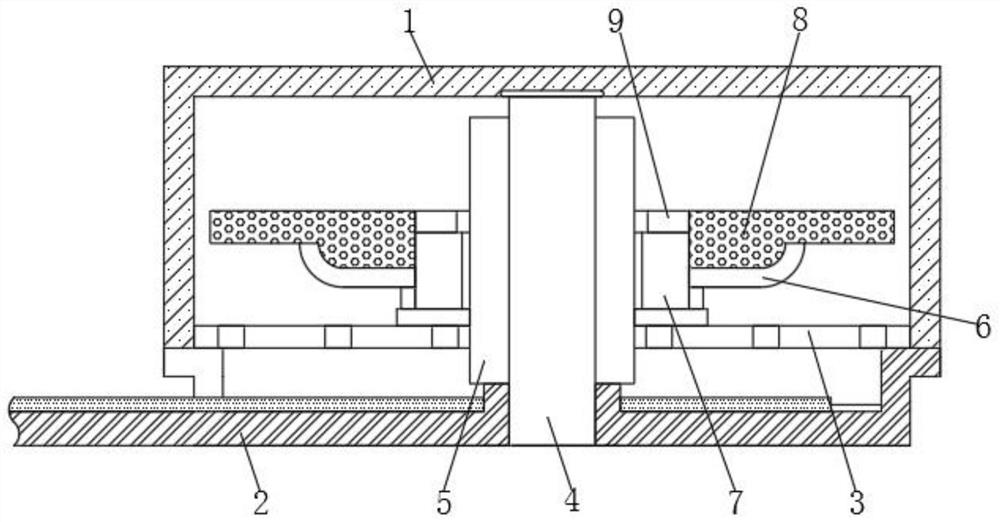

[0092] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the spring 3 is arranged on the inner top wall of the lower casing 2 in the form of a leaf spring, and the outer locking block 6, the ring magnet 7, the vibrator 8 and the inner locking block 9 is arranged above the spring 3, and the installation method of the outer lock block 6, the ring magnet 7, the vibrator 8 and the inner lock block 9 is a mirror image of that in Embodiment 1;

[0093] Since the spring 3 is a leaf spring, it does not require heat treatment and does not protrude, so it is easy to handle during the manufacturing process, thereby reducing the defective rate, all parts are assembled in the lower case 2, and the upper case 1 is assembled after final inspection, Therefore, the assembly is simple and the defective rate is reduced.

[0094] A linear motor with a shaft, when working, by setting the bobbin 4 between the upper casing 1 and the lower casing 2, the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com