A new type of engraving equipment

A kind of equipment and engraving technology, applied in the field of engraving, can solve the problems of engraving accuracy to be improved, insufficient stability of moving operation, etc., and achieve the effects of automatic and stable positioning and clamping, low noise and high transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

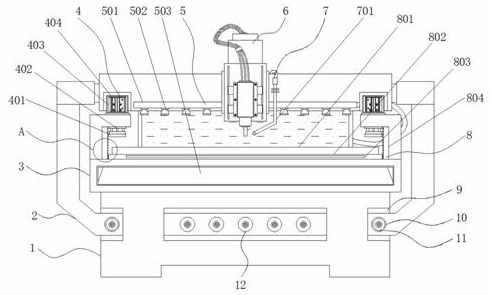

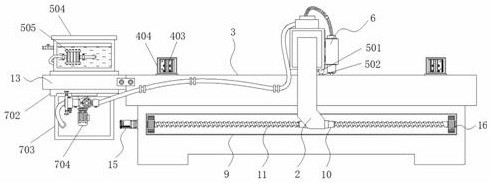

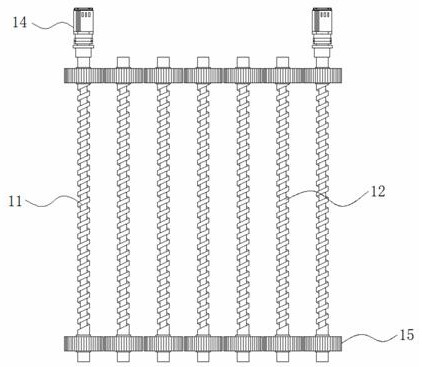

[0035] Example 1: See Figure 1-6 , a new type of engraving equipment, including a base 1 and a processing table 3, the top of the base 1 is provided with a processing table 3, the outside of the processing table 3 is provided with a gantry-type mobile frame 2, and the middle position of the top of the gantry-type mobile frame 2 is provided There are processing components 6, one end of the processing table 3 is fixedly connected with a fixed table 13, the top of the processing table 3 both sides is provided with a clamping positioning mechanism 4, the bottom of one end of the gantry type mobile frame 2 is provided with a flushing mechanism 5, and the fixed table 13 The bottom end is provided with a chip suction mechanism 7, the bottom end of the processing part 6 is provided with a placement structure 8, and the inside of the base 1 is provided with a transmission mechanism;

[0036] see Figure 1-6, a new type of Jingdiao equipment also includes a transmission mechanism, the...

Embodiment 2

[0039] Embodiment 2: The clamping and positioning mechanism 4 is made up of splint 401, telescoping rod 402, cylinder 403 and housing 404, and housing 404 is fixedly connected on both sides of the top of processing table 3, and the inside of housing 404 is provided with cylinder 403, and cylinder The model of 403 can be SC, the output end of the cylinder 403 is provided with a telescopic rod 402, and the bottom end of the telescopic rod 402 is fixedly connected with a splint 401;

[0040] Two groups of cylinders 403 are arranged on both sides of the top of the processing table 3 and are distributed symmetrically about the vertical center line of the processing table 3;

[0041] Specifically, such as figure 1 , figure 2 and Figure 4 As shown, start the housing 404 on the external controller at the same time, the output end of the housing 404 pushes the cylinder 403 out, the telescopic rod 402 presses the template 801 from above, the housing 404 can effectively prevent debri...

Embodiment 3

[0042] Embodiment 3: The flushing mechanism 5 is made up of a water distribution pipe 501, a nozzle 502, a drainage channel 503, a water tank 504 and a high-pressure water pump 505. The water distribution pipe 501 is fixedly connected to the bottom of one end of the gantry type mobile frame 2, and the bottom end of the water distribution pipe 501 is provided with The nozzle 502 and the drainage channel 503 are arranged inside the processing table 3. The water tank 504 is fixedly connected to the top of the fixed table 13. A high-pressure water pump 505 is arranged on one side of the water tank 504. The model of the high-pressure water pump 505 can be ISGD, high-pressure water pump 505 The input end of the water pump 505 communicates with the inside of the water tank 504 through a conduit, and the output end of the high-pressure water pump 505 communicates with the water distribution pipe 501 through a conduit;

[0043] The bottom end inside the drainage channel 503 is an inclin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com