Automatic tea dragon bead packaging technology

An automatic packaging, tea dragon ball technology, applied in packaging, packaging machines, transportation packaging and other directions, can solve the problems of low degree of automation, low packaging efficiency, a lot of manpower and time, etc., to achieve good market returns, save manpower and time, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

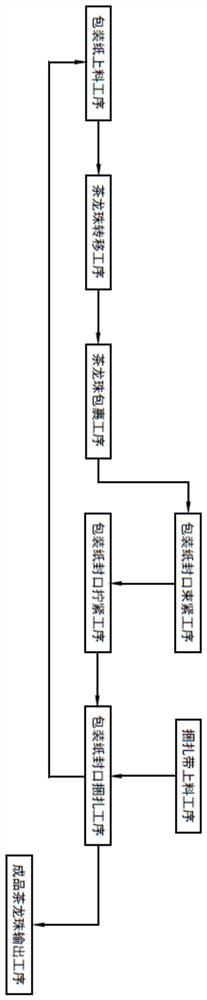

[0067] Such as figure 1 Shown, a kind of tea dragon ball automatic packaging process comprises the following production steps:

[0068] Step 1, wrapping paper feeding process, the wrapping paper is stored in the wrapping paper storage box 203, and the adsorption slide bar 505 in the support assembly 501 rises to absorb the lowermost single wrapping paper in the wrapping paper storage box 203;

[0069] Step 2, the tea dragon ball transfer process, when the support assembly 501 moves to the tea dragon ball transfer station in step 1, the feeding roller 303 carries the tea dragon balls output from the tea dragon ball loading bin 301 and transfers a single tea dragon ball to the tea dragon ball during the rotation process. On the single wrapping paper that the support assembly 501 absorbs;

[0070] Step 3, tea dragon ball wrapping process, when the support assembly 501 moves to the tea dragon ball wrapping station in step 2, the adsorption slide bar 505 in the support assembly 50...

Embodiment 2

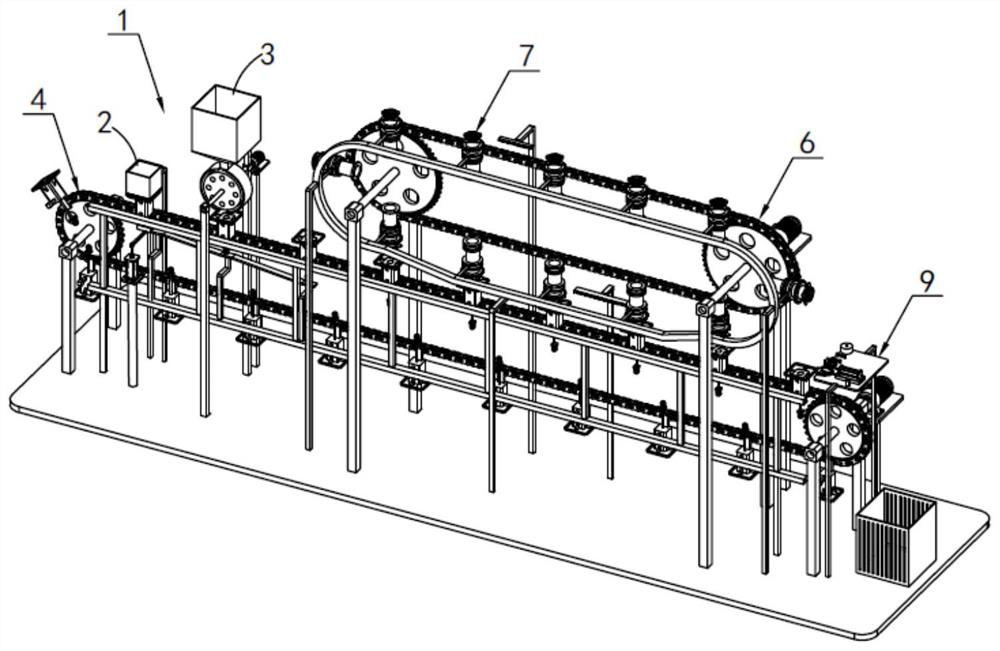

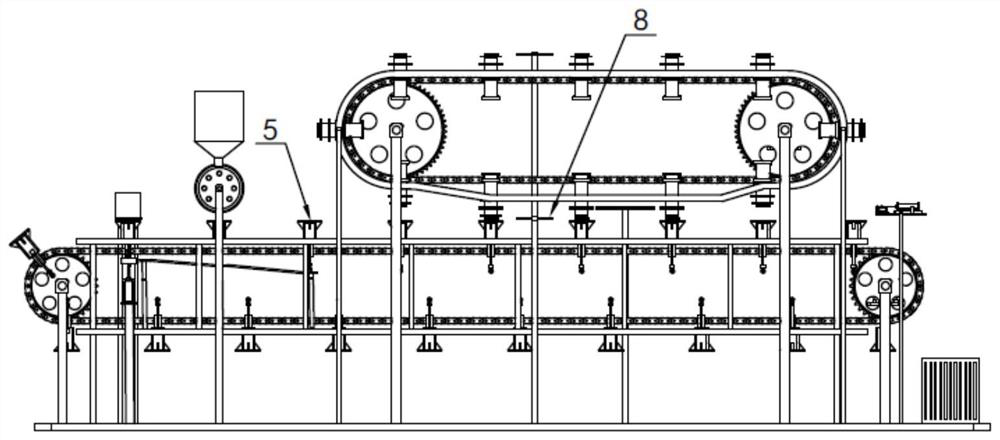

[0085] Such as Figure 2 to Figure 23 As shown, a tea dragon ball automatic packaging equipment includes a feeding device 1, and the feeding device 1 includes a first feeding device 2 and a second feeding device 3, and a No. 1 rotary device is provided below the feeding device 1 4. The No. 1 turning device 4 is provided with a number of supporting mechanisms 5 equidistantly distributed. The supporting mechanism 5 includes a supporting component 501 and a wrapping component 502. The supporting component 501 is used to absorb the first upper The single wrapping paper on the bottom layer of the feeding device 2 and makes the middle of the wrapping paper in a preliminary concave state during the moving process. The wrapping component 502 is used to accept the single tea dragon ball output from the second feeding device 3 and place it on the supporting component. Under the action of 501, the initially concave wrapping paper is completely wrapped outside the tea dragon ball, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com