Vegetation concrete

A technology of planting concrete and loam, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as increased pH value, limited firmness, and unstable attachment, etc., to improve strength and other indicators , Improve strength and durability, enhance the effect of fertility characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

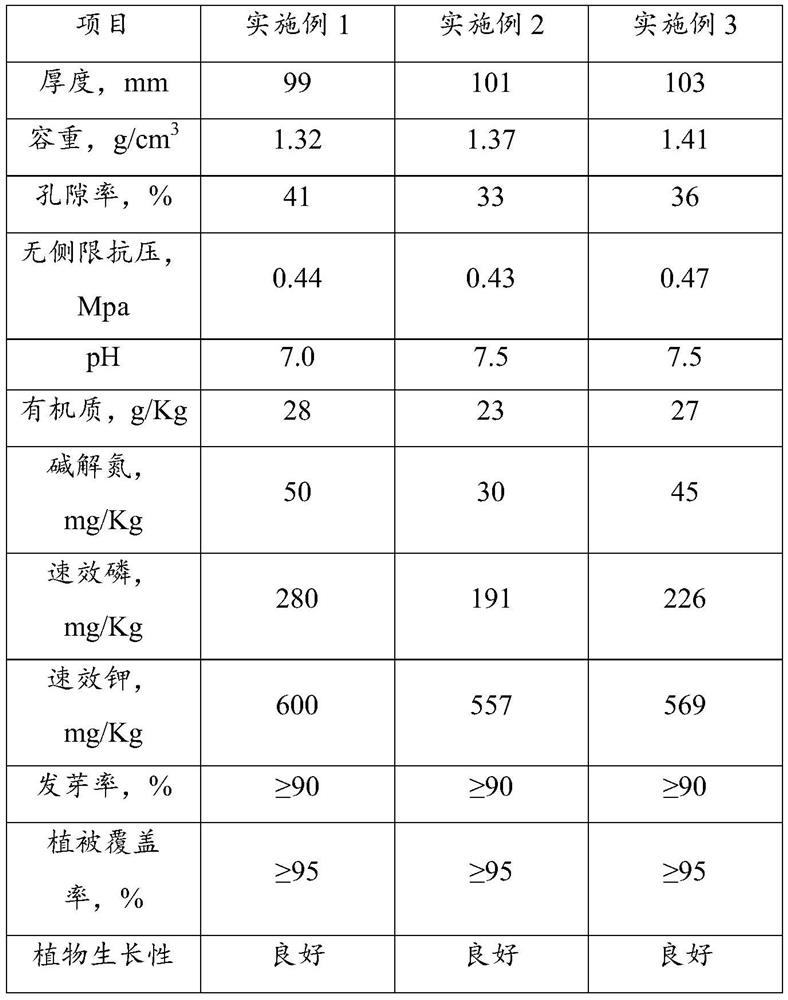

Embodiment 1

[0032] In the present embodiment, vegetation concrete is made up of the following components by weight:

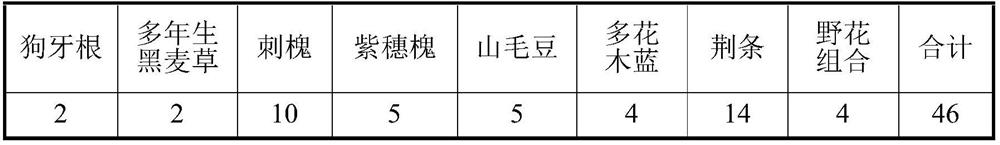

[0033] 10 parts of phosphogypsum, 3 parts of fly ash, 1 part of superfine silica fume, 70 parts of nutrient loam, 8 parts of organic fertilizer, 1 part of expanded perlite, 1 part of xanthan gum, 2 parts of plant fiber, 1 part of natural inorganic fiber material , 2 parts of plant growth improver, 0.5 part of inorganic nano water retaining agent, 0.1 part of plant-type air-entraining agent, and 1 part of plant seed.

[0034] It can be obtained after mixing the formula materials evenly according to the above ratio.

Embodiment 2

[0036] In the present embodiment, vegetation concrete is made up of the following components by weight:

[0037] 15 parts of phosphogypsum, 6 parts of fly ash, 3 parts of superfine silica fume, 48 parts of nutrient loam, 10 parts of organic fertilizer, 3 parts of expanded perlite, 3 parts of xanthan gum, 3 parts of plant fiber, 2 parts of natural inorganic fiber material , 5 parts of plant growth improver, 1 part of inorganic nano-water retaining agent, 0.3 part of plant-type air-entraining agent, and 1 part of plant seed.

[0038] It can be obtained after mixing the formula materials evenly according to the above ratio.

Embodiment 3

[0040] In the present embodiment, vegetation concrete is made up of the following components by weight:

[0041]13 parts of phosphogypsum, 4 parts of fly ash, 2 parts of superfine silica fume, 58 parts of nutrient loam, 8 parts of organic fertilizer, 2 parts of expanded perlite, 2 parts of xanthan gum, 3 parts of plant fiber, 2 parts of natural inorganic fiber material , 4 parts of plant growth improver, 0.7 part of inorganic nano-water retaining agent, 0.2 part of plant-type air-entraining agent, and 1 part of plant seed.

[0042] It can be obtained after mixing the formula materials evenly according to the above ratio.

[0043] In Examples 1 to 3, the nutrient loam includes the following components in weight percentage: raw soil 50%, fine sand 35%, waste straw powder 14%, ferrous sulfate 0.3%, and compound fertilizer 0.7%. At the same time, in order to ensure soil fertility, humus about 15% of the total mass of raw soil, fine sand, waste straw powder, ferrous sulfate, and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com