Hydrocracking method of inferior diesel oil raw material

A technology for hydrocracking and low-quality diesel oil, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problems of high hydrogen consumption, low product selectivity, easy poisoning and deactivation of hydrocracking catalysts, etc., and achieves The effect of less non-framework aluminum, increased aromatics content, and abundant secondary pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation process of hydrocracking catalyst B is as follows:

[0049] First, the Y molecular sieve in the hydrocracking catalyst B is prepared by multiple dealumination and three times of water roasting:

[0050] (1) Use NaY zeolite as raw material to exchange with ammonium chloride solution. The treatment conditions are: according to the ratio of NaY molecular sieve (dry basis): ammonium chloride: water = 1:0.7:10, exchange at 85°C for 1h, filter Afterwards, it was washed with deionized water and dried at 120°C for 4 hours.

[0051] (2) The molecular sieve obtained in the step (1) is subjected to the first hydrothermal calcination treatment, the calcination temperature is 600° C., and the calcination is carried out under 100% water vapor atmosphere for 2 hours.

[0052] (3) The molecular sieve obtained in step (2) is according to the ratio of molecular sieve (dry basis): citric acid: sulfuric acid: water = 1: 0.15: 0.05: 8, first add water to the molecular sieve...

Embodiment 1

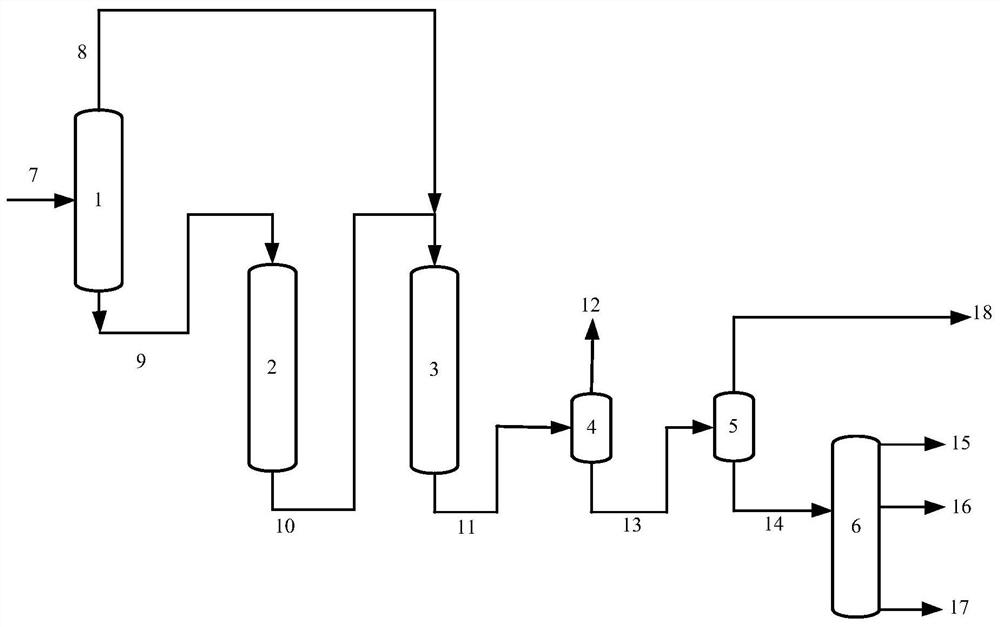

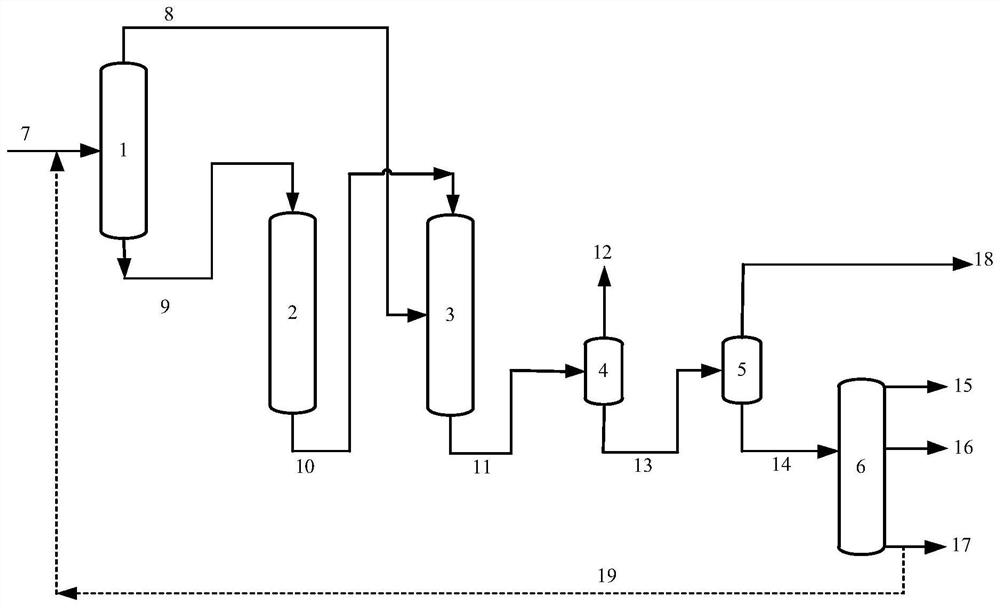

[0072] Diesel feed oil C is cut into light diesel oil fraction C1 (235°C) at a cut point of 235°C. The heavy diesel oil fraction C2 is mixed with hydrogen and enters the hydrofinishing reactor, where it contacts with the hydrofinishing catalyst RN-411, and undergoes hydrodesulfurization, denitrogenation and selective hydrogenation saturation reactions under hydrofinishing reaction conditions; light diesel oil fraction After C1 is mixed with the hydrofining reaction effluent, it enters the hydrocracking reactor and reacts with the hydrocracking catalyst RHC-100. The hydrocracking reaction effluent is separated and fractionated to obtain BTX-rich fractions and hydrogenated diesel fractions. The reaction conditions are shown in Table 3, and the product yields and properties are shown in Table 4.

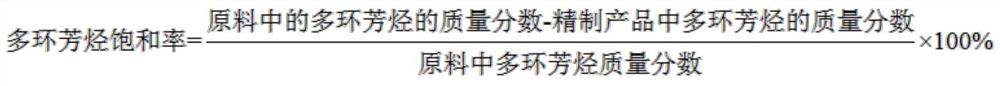

[0073] It can be seen from Table 4 that the saturation rate of polycyclic aromatic hydrocarbons in the hydrofinishing process is 80.8%, and the selectivity of single-ring aromatic hydro...

Embodiment 2

[0075] Diesel feed oil C is cut into light diesel oil fraction C1 (235°C) at a cut point of 235°C. The heavy diesel oil fraction C2 is mixed with hydrogen and enters the hydrofinishing reactor, where it contacts with the hydrofinishing catalyst RN-411, and undergoes hydrodesulfurization, denitrogenation and selective hydrogenation saturation reactions under hydrofinishing reaction conditions; light diesel oil fraction After C1 is mixed with the hydrofining reaction effluent, it enters the hydrocracking reactor and reacts with the hydrocracking catalyst RHC-100. The hydrocracking reaction effluent is separated and fractionated to obtain BTX-rich fractions and hydrogenated diesel fractions. Wherein 50% by mass of the hydrogenated diesel fraction is returned to the inlet of the hydrocracking reaction zone for further conversion. The reaction conditions are shown in Table 3, and the product yields and properties are shown in Table 4.

[0076] It can be seen from Table 4 that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell constant | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com