Flattening and dismounting control method suitable for cloth printing and dyeing

一种布料、一体的技术,应用在布料印染的压平与拆装控制领域,能够解决降低工作经济效益、位置偏移、易起褶皱等问题,达到保证收卷工作质量、提高经济效益、保证加工质量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions in the embodiments of the present invention will be clearly and completely described below. The embodiments of the present invention and all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

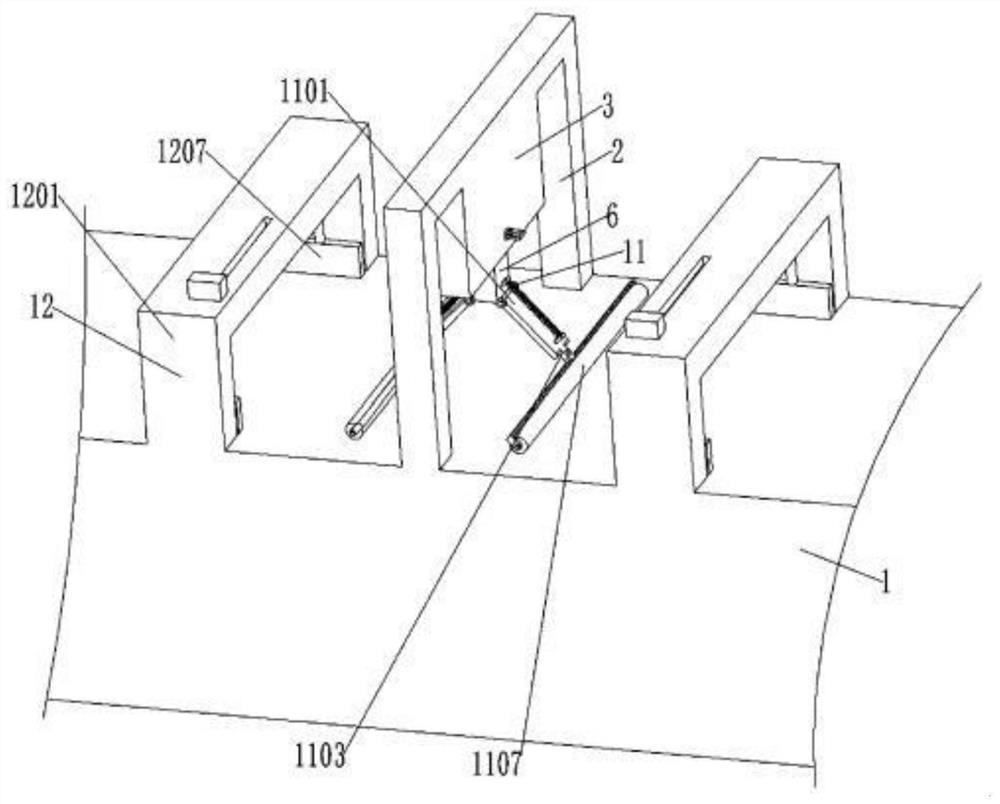

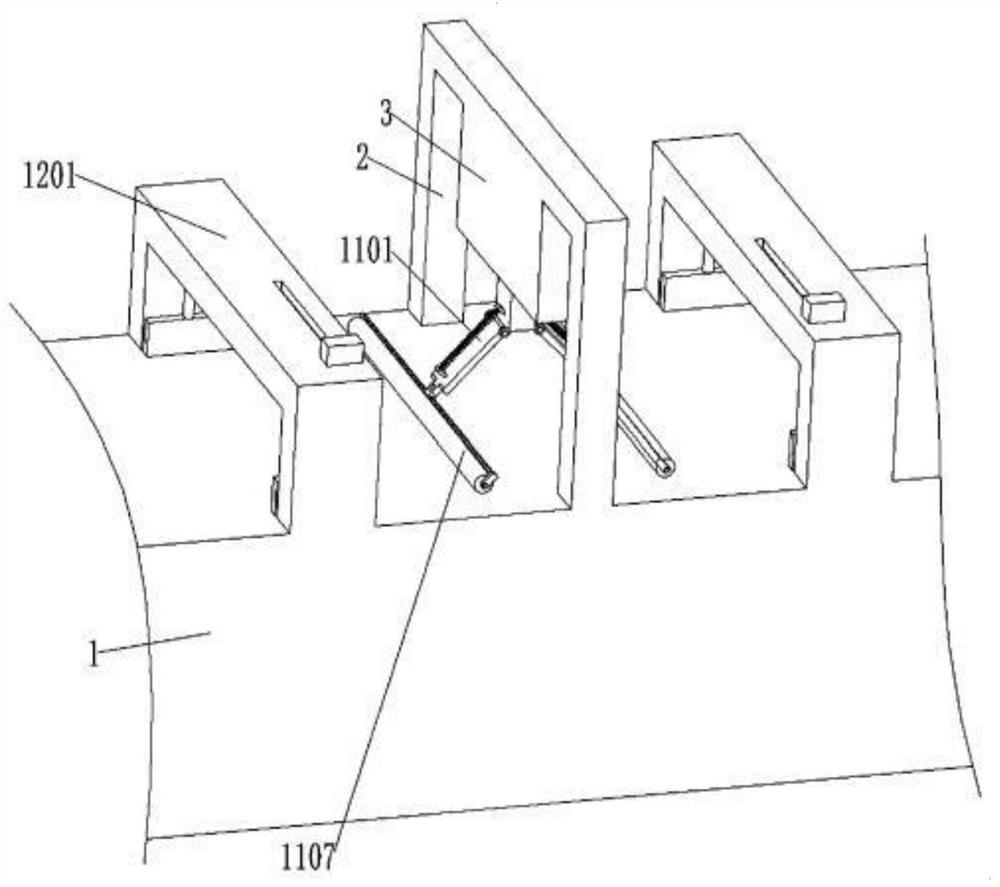

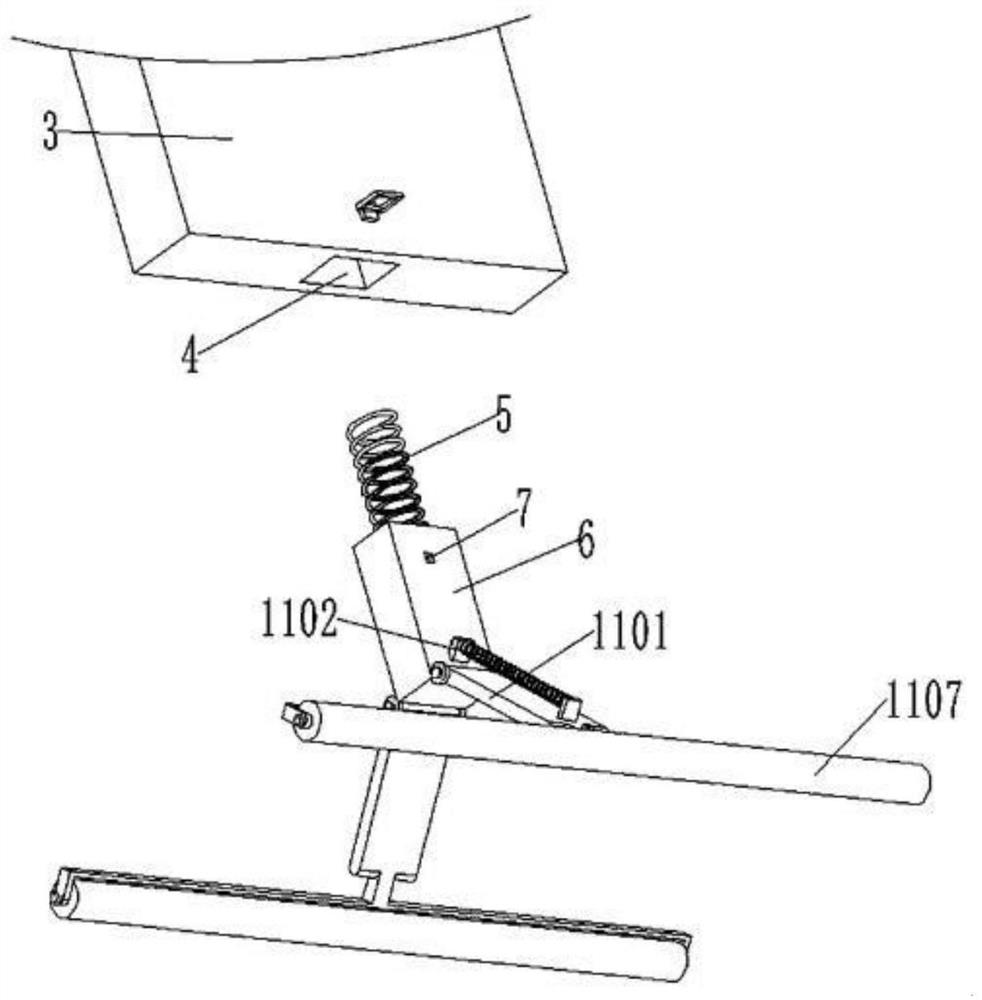

[0032] see figure see Figure 1 to Figure 8 , the present invention provides a technical solution: a flattening and disassembly control method suitable for cloth printing and dyeing, the method is realized based on a cloth feeding mechanism, and the cloth feeding mechanism includes a conveying platform 1, a flattening device 11 and a Limiting structure 12;

[0033] The transmission platform 1 is welded and connected with a first bracket 2, and the first bracket 2 is integrally formed with a fixed body 3. The fixed body 3 is provided with a groove 4, and the groove 4 is integrally formed and connected with a first connection spring 5. The other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com