Waterproof breathable water-soluble protective material

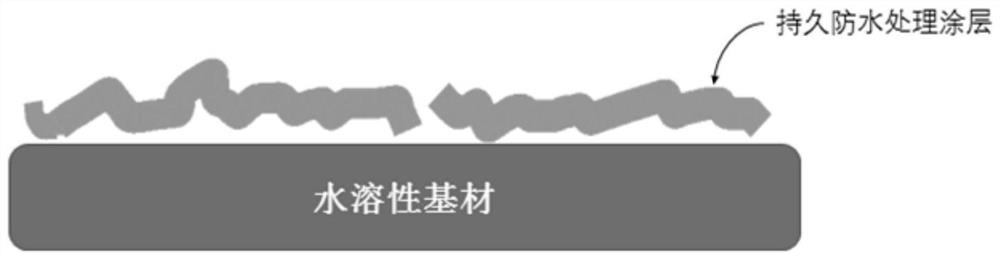

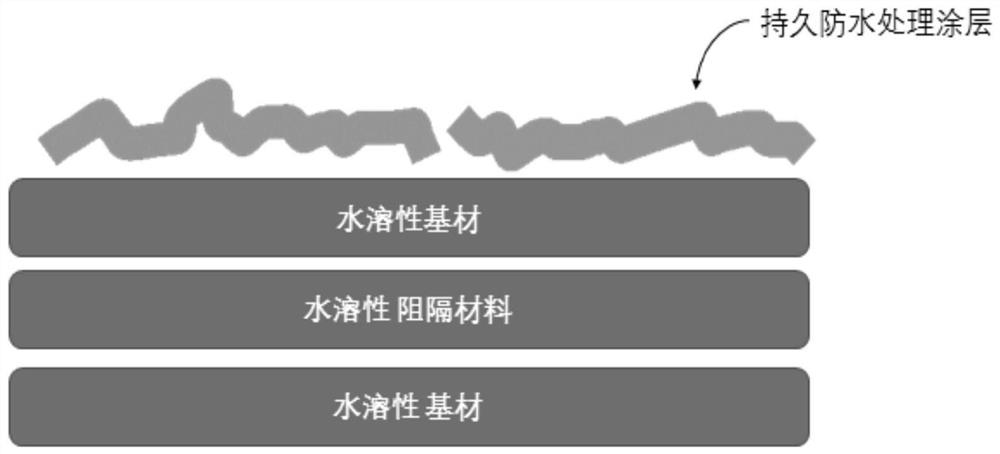

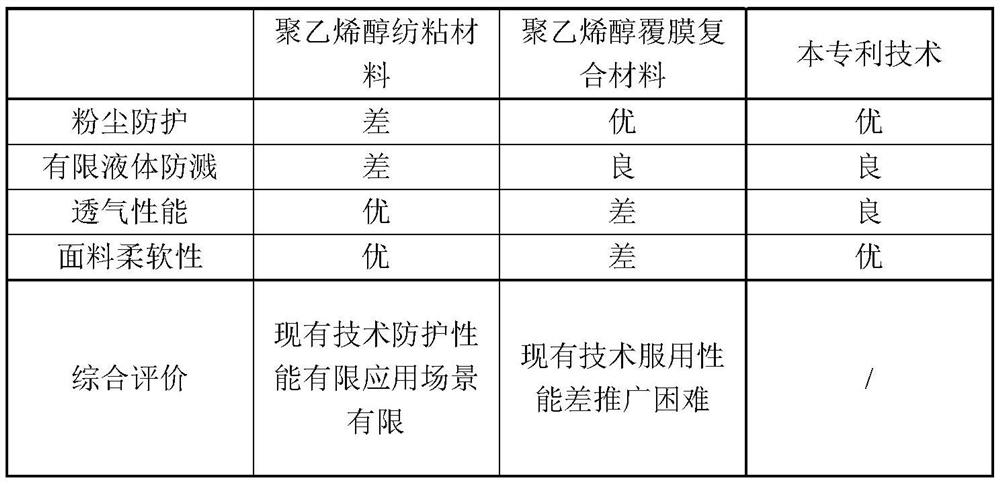

A protective material, waterproof and breathable technology, applied in synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve the problems of poor wearing performance, rigid materials, lack of breathability, etc., to improve wearing comfort. , Improve the performance of taking, maintain the effect of water-soluble energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The dissolving temperature is 80 degrees centigrade, and the polyvinyl alcohol spun-bonded non-woven fabric of 45 grams per square meter is passed through the hydrophobic coating nozzle, and the hydrophobic coating treatment is carried out by spraying.

[0046] The hydrophobic coating material used was an alkoxysilane coating with a solids content of 1%. Afterwards, the material is dried in an environment of 105 degrees Celsius to remove the solvent while cross-linking and curing the surface of the alkoxysilane.

[0047] The added amount of the coating is 0.1% of the mass of the non-woven fabric.

Embodiment 2

[0049] The dissolving temperature is 80 degrees centigrade, and the polyvinyl alcohol spun-bonded non-woven fabric of 45 grams per square meter is immersed in the hydrophobic coating solution, and the hydrophobic coating treatment is carried out by dipping method.

[0050] The hydrophobic coating material used was an alkoxysilane coating with a solids content of 1%. Afterwards, the material is dried in an environment of 105 degrees Celsius to remove the solvent while cross-linking and curing the surface of the alkoxysilane.

[0051] The added amount of the coating is 0.5% of the mass of the protective material.

Embodiment 3

[0053] The dissolving temperature is 80 degrees centigrade, and the polyvinyl alcohol spun-bonded non-woven fabric of 45 grams per square meter is passed through the hydrophobic coating nozzle, and the hydrophobic coating treatment is carried out by spraying.

[0054] The hydrophobic coating material used was an alkoxysilane coating with a solids content of 2%. Afterwards, the material is dried in an environment of 105 degrees Celsius to remove the solvent while cross-linking and curing the surface of the alkoxysilane.

[0055] The added amount of the coating is 0.5% of the mass of the protective material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com