Full-automatic storage battery O-shaped ring adding device

An O-ring and battery technology, applied in the direction of lead-acid battery, lead-acid battery construction, assembling battery machine, etc. , The effect of reducing defective product rate and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

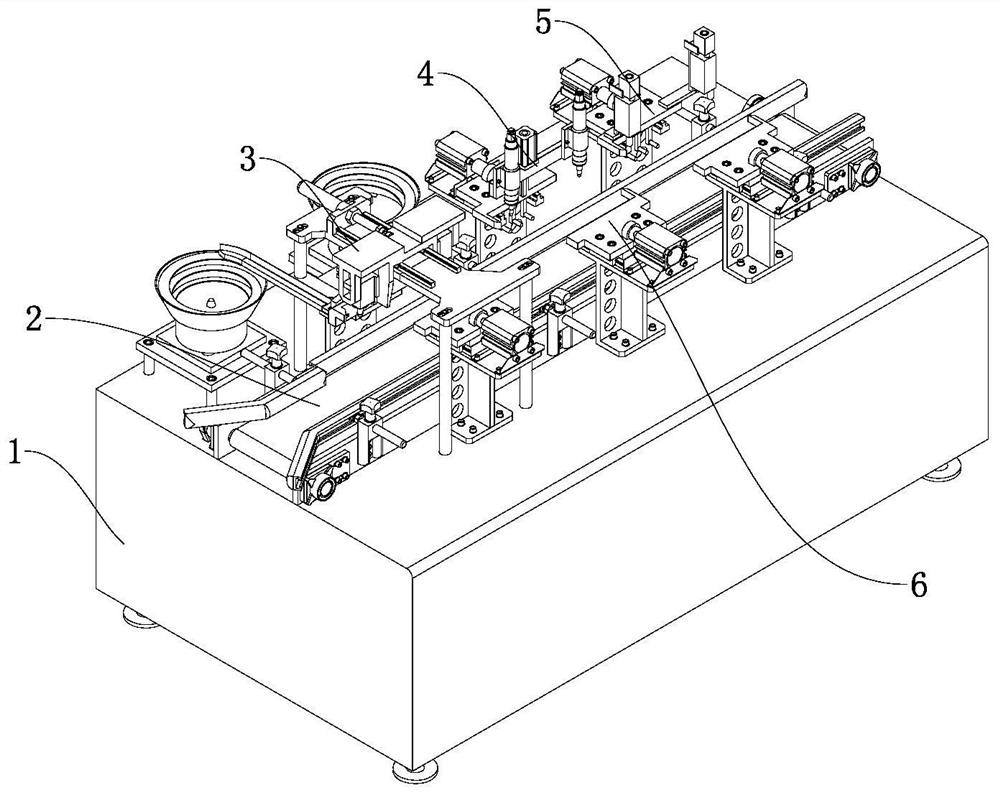

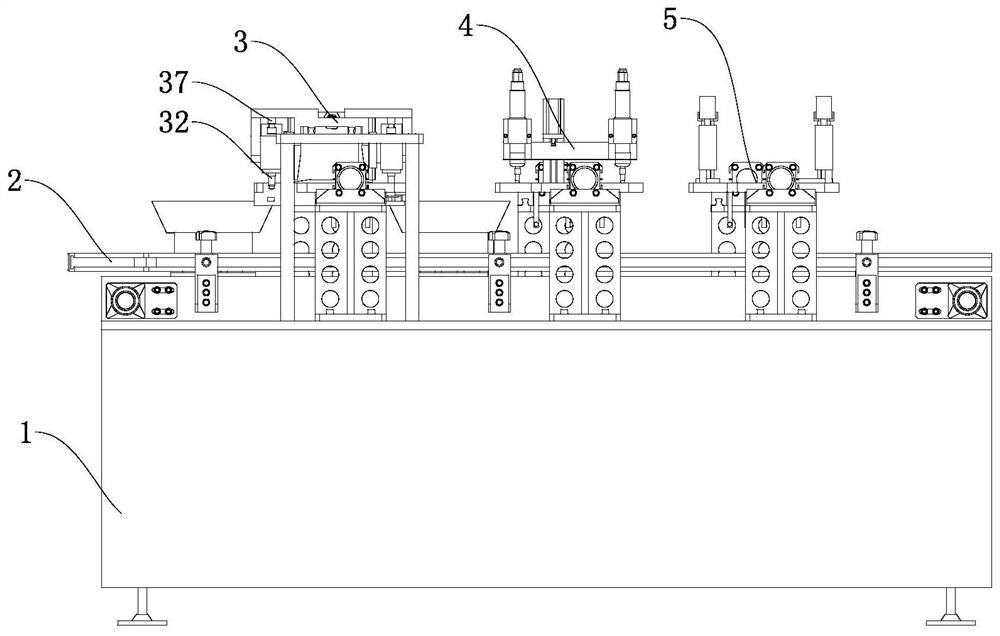

[0037] Such as figure 1 As shown, a fully automatic battery adding O-ring device is used to automatically add O-rings to the positive and negative poles on the top surface of the battery. The fully automatic battery adding O-ring device includes a bracket 1 on which There is a conveyor belt 2 for transporting batteries to be added with O-rings, and a set of O-ring mechanisms 3, a push-down mechanism 4, and a detection mechanism 5 arranged in sequence from the upstream end of the conveyor belt 2 to the downstream end; the set of O-ring mechanisms 3 is used to put an O-ring on the top of each terminal post, the push-down mechanism 4 is used to press down the O-ring on the top of the terminal post, and the detection mechanism 5 is used to detect and confirm the two The O-ring is successfully assembled on the terminal post.

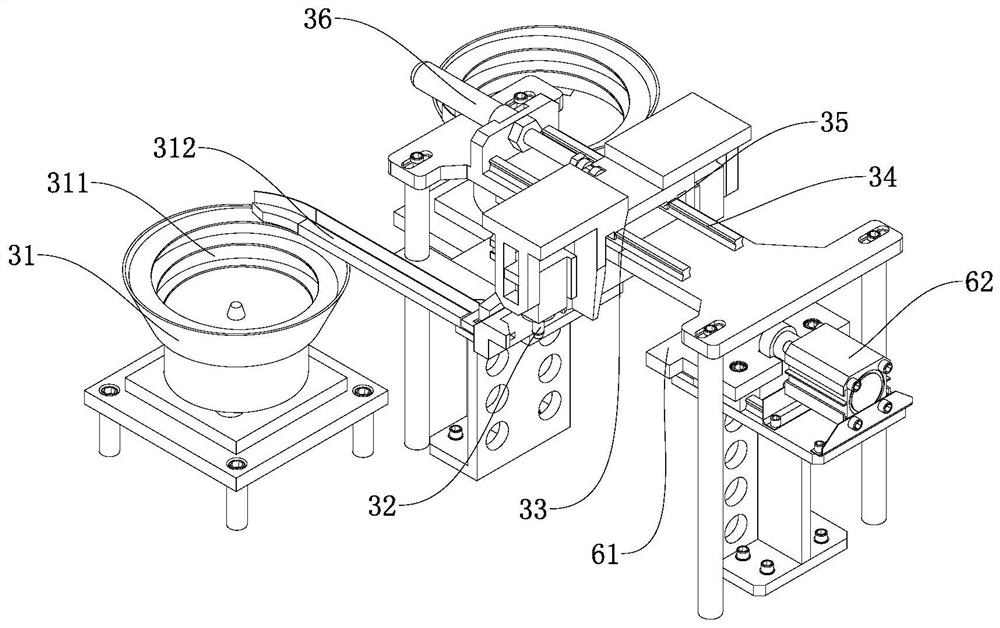

[0038] Such as figure 2 with 3 As shown, the shown O-ring mechanism 3 includes a screening vibrating plate 31 for supplying one O-ring at a time, and is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap