Fully automatic feeding pipe cutting machine

A pipe cutting machine, fully automatic technology, applied in the direction of tubular objects, applications, laser welding equipment, etc., can solve the problems of damage to the laser pipe cutting machine, material hook stuck, and reduce processing efficiency, so as to improve the feeding rate and loading Material accuracy, avoid feeding confusion, and improve cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

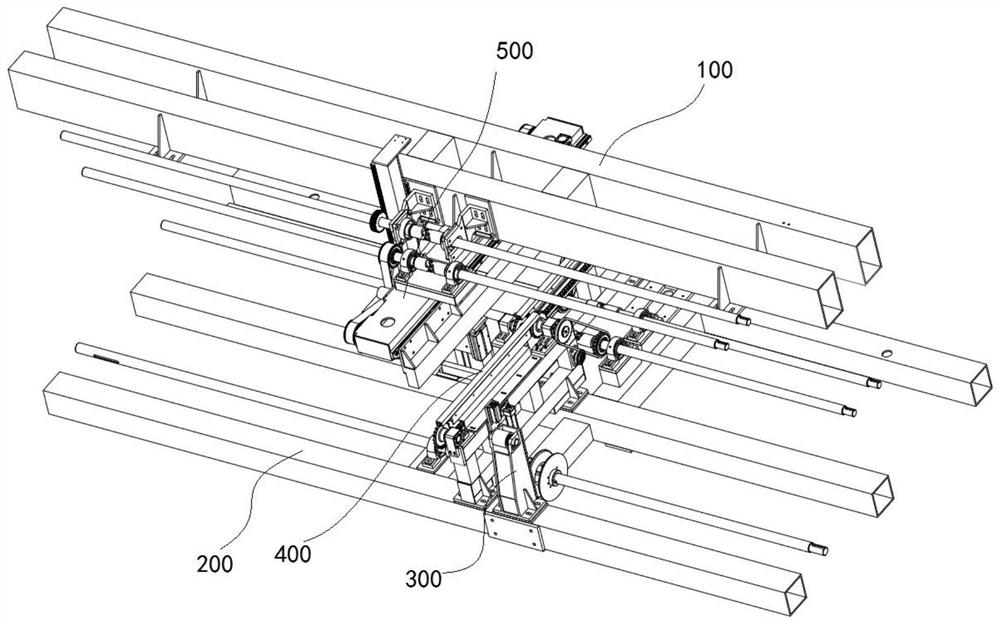

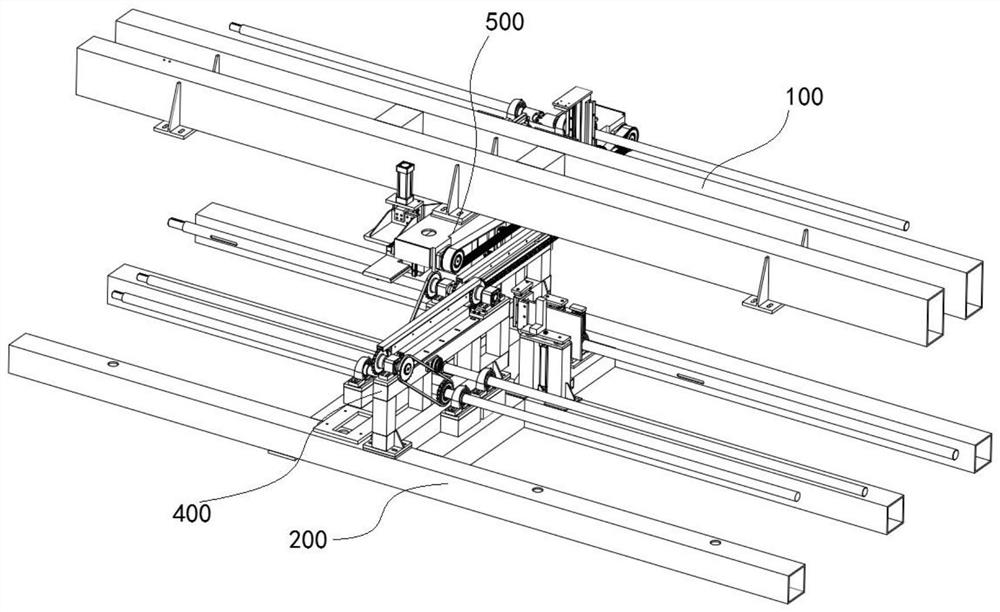

[0033]Such as Figure 1-11 As shown, a fully automatic pipe feeding and cutting machine in this embodiment includes a frame 100 and a base 200. The base 200 is provided with a plurality of auxiliary feeding structures 300 for placing and transporting the pipes to be cut. A plurality of automatic conveying mechanisms 400 for cutting pipes. The frame 100 and the base 200 are provided with a plurality of extending and clamping mechanisms 500 for extending, clamping and transporting the pipes to be cut.

[0034] The number of auxiliary feeding structure 300, automatic conveying mechanism 400, and jacking clamping mechanism 500 shown in the drawings of this embodiment is one, but the protection scope of the present invention is by no means limited to one, and multiple also belong to the protection scope of the present invention , the pipe to be cut is preferably a square pipe, and laser cutting is preferred when cutting the pipe.

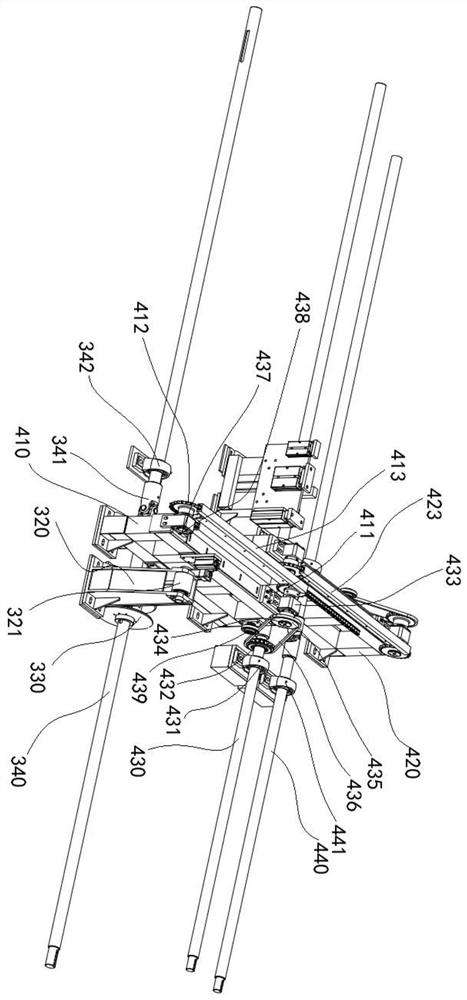

[0035] The auxiliary feeding structure 300 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com