Buttonhole punching equipment for garment production

A technology of punching equipment and buttonholes, which is applied in the field of garment processing and can solve problems such as fixing and difficult garments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

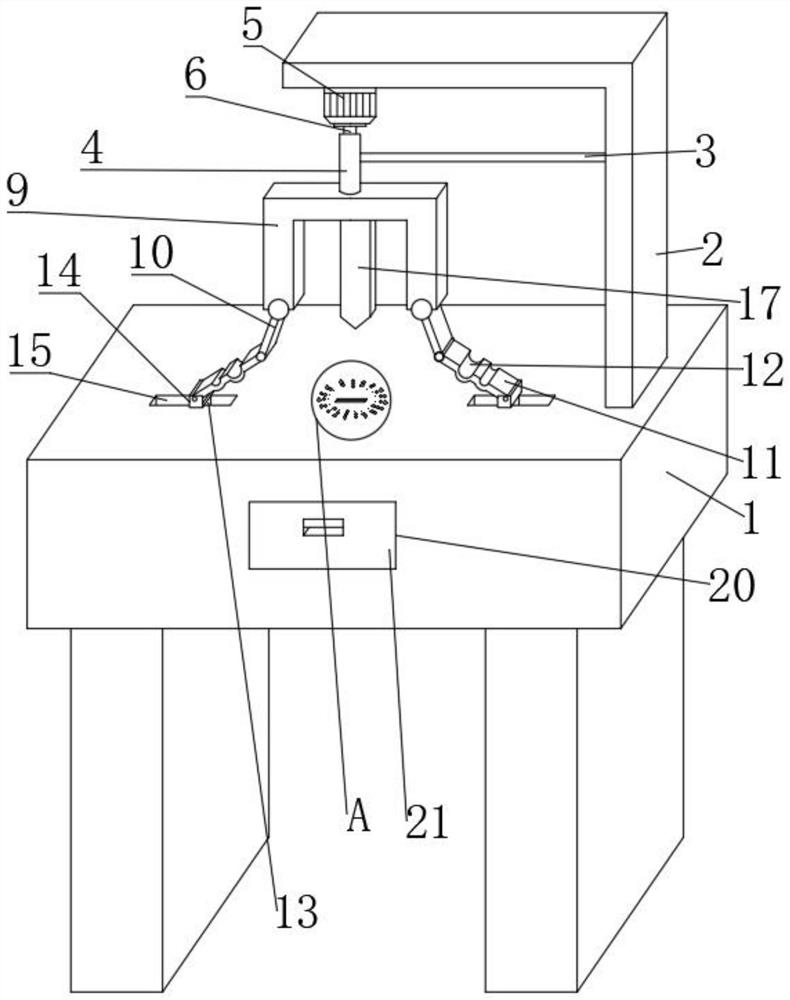

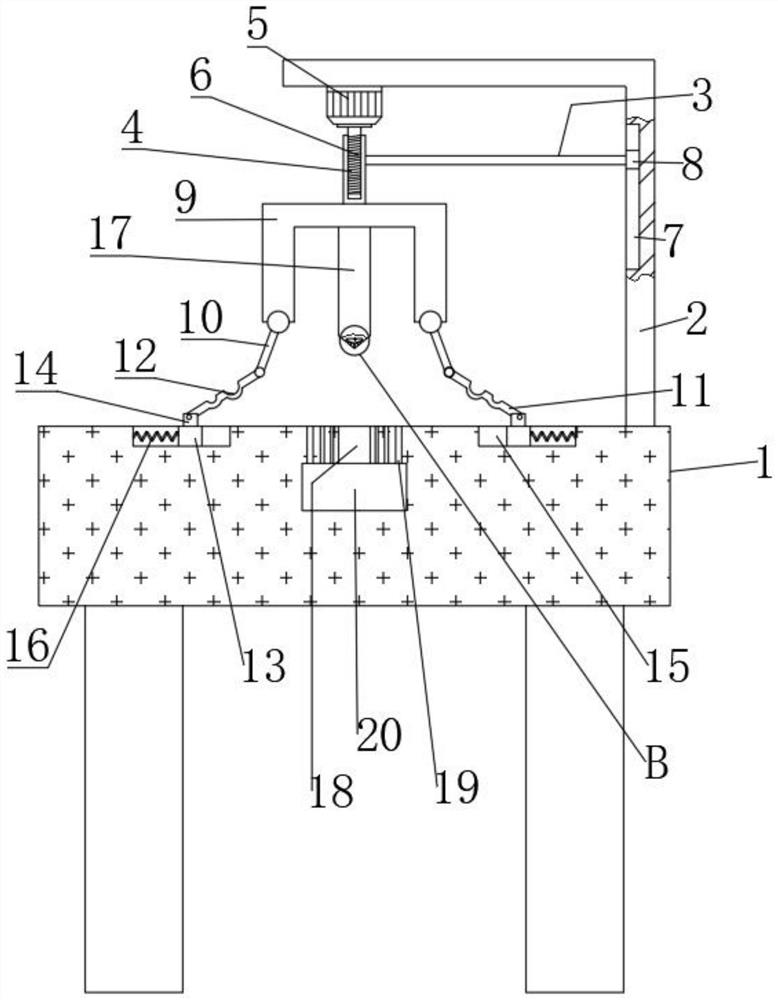

[0032] refer to Figure 1-3 , a buttonhole punching device for clothing production, comprising a workbench 1, a support plate 2 is fixed on one side of the top of the workbench 1 by bolts, the cross section of the support plate 2 is set in an L shape, and a motor 5 is fixed on the bottom of the support plate 2 by bolts, The output shaft of the motor 5 is connected with a screw 6, the bottom of the screw 6 is sheathed and threadedly connected with a casing 4, the inner side of the support plate 2 is provided with a limiting groove 7, and the limiting groove 7 is slidingly connected with a limiting block 8, and the limiting block 8 and the sleeve The same support rod 3 is fixed between the tubes 4 by bolts, and the bottom of the casing 4 is fixed with a fixed plate 9 by bolts. The section of the fixed plate 9 is set in a U shape, and both sides of the bottom of the fixed plate 9 are connected with the first pressure plate through bearing rotation. 10. The bottom of the first pre...

Embodiment 2

[0039] refer to Figure 1-4 , a buttonhole punching device for clothing production, the bottom of the pressing part 12 is fixed with a pressing block 22 by bolts, the cross section of the pressing block 22 is set in a tadpole shape, and the pressing block 22 can be used to press the clothing in points, Improves fixation and prevents slipping.

[0040] In the present invention, a pressing groove 23 is opened on the surface of the pressing block 22, and the pressing groove 23 is set in a tooth shape, which can effectively improve the roughness of the surface of the pressing block 22, further improve the fixing effect, and prevent slipping.

[0041] During use, you can use the pressing block 22 to fix the clothing with a certain elastic fabric, such as denim clothing, the pressing block 22 cross-section is set into a tadpole shape, you can use the pressing block 22 to compress the clothing at points, improve Fixing effect to prevent slipping, further setting the pressing groove ...

Embodiment 3

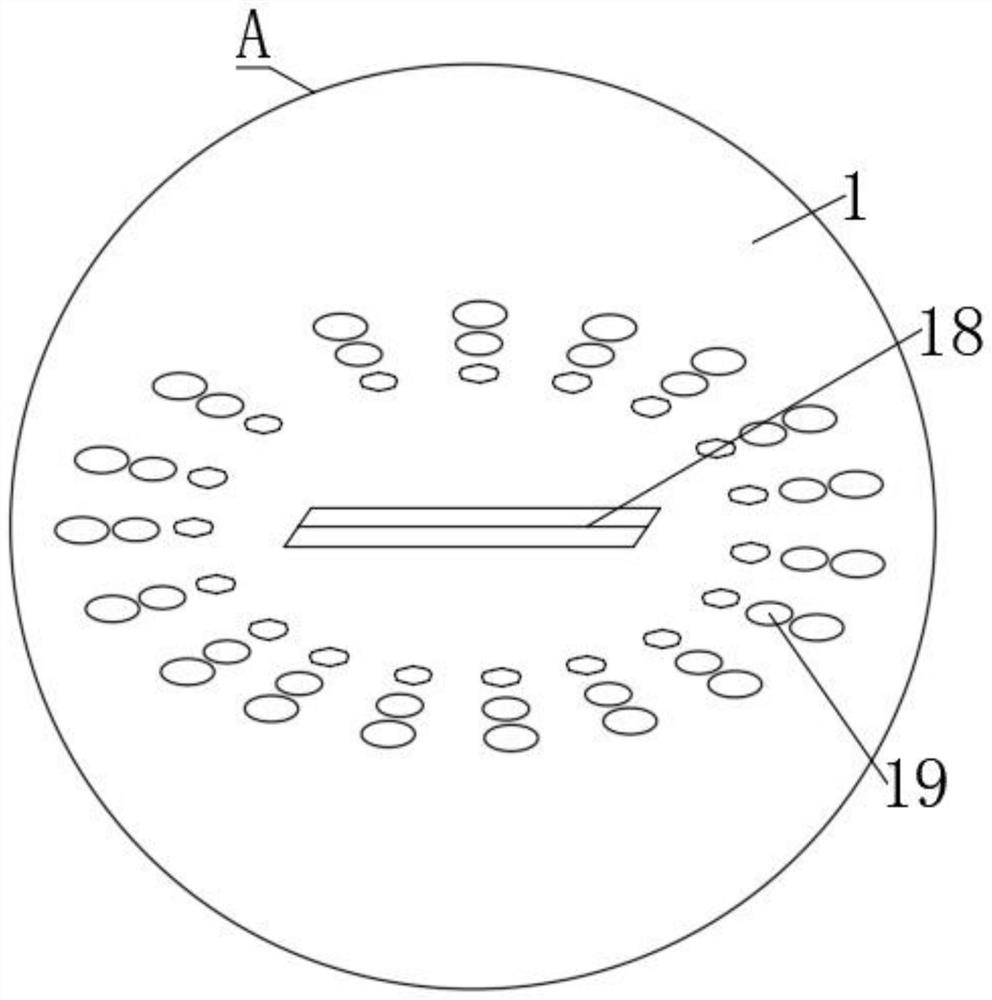

[0043] refer to Figure 1-3 and Figure 5 , a buttonhole punching device for clothing production, the bottom of the pressing part 12 is provided with a plurality of ball grooves 24 distributed in an annular array, and the ball grooves 24 are movably connected with pressing beads 25, which can be used for clothing with poor fabric elasticity. Fixed, so as to effectively prevent scratches on this type of clothing.

[0044] When in use, you can use the pressing beads 25 to fix the garments with poor fabric elasticity. Rolling to effectively prevent scratches on this type of clothing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com