Low-torque spinning device

A low-torque, spinning-frame technology, used in spinning machines, continuous-winding spinning machines, textiles and papermaking, etc., to solve problems such as low spindle speed limits, poor yarn softness, and difficult production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

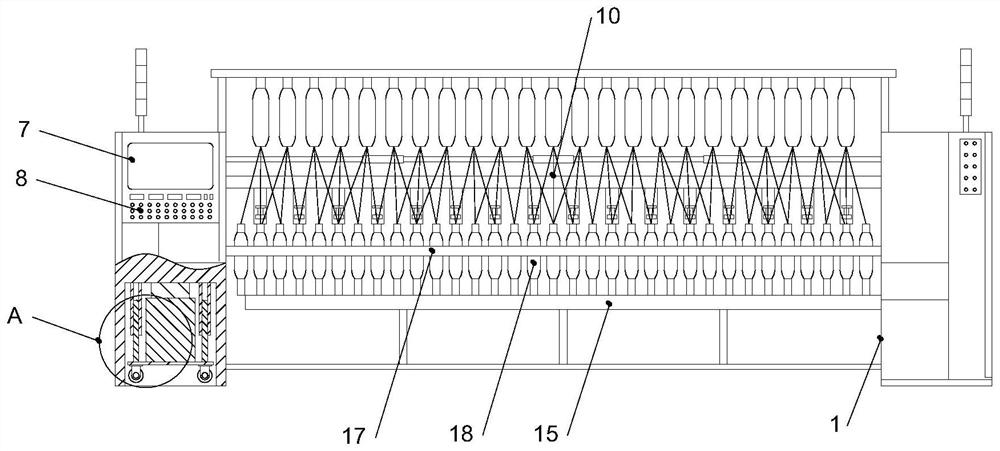

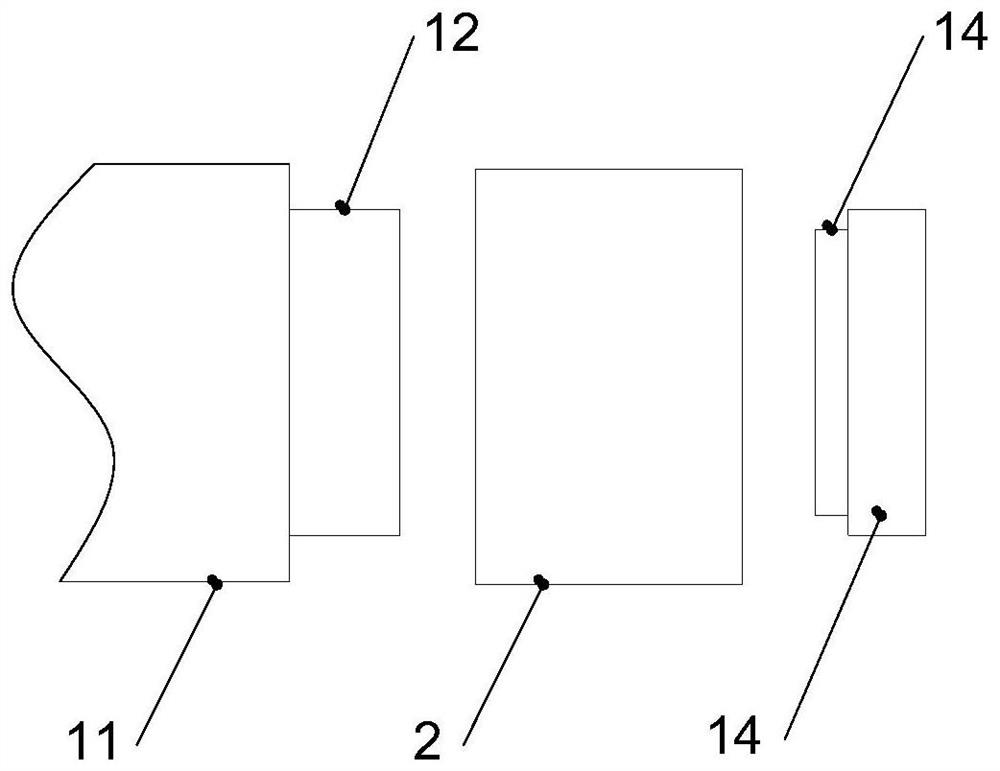

[0030] like figure 1 and figure 2 Shown, a kind of low torque spinning device comprises spinning frame 1, and described spinning frame 1 comprises body 11, front roller 12, steel ring 13 and traveler 14, and described front roller 12 is fixedly connected with body 11, and described The steel ring 13 is fixedly connected to the body 11, and the traveler 14 is rotationally connected to the steel ring 13; the leaf plate 15, the leaf plate 15 is fixedly connected to the body 11; the gear motor 16, the gear motor 16 is fixedly connected to the body 11; the dragon belt 17, the dragon belt 17 is connected to the output end of the reduction motor 16; the single wheel 18, the single wheel 18 is connected to the body 11 in rotation, and the single wheel 18 is connected to the body through static friction Dragon belt 17 is connected, and the quantity of described single wheel 18 is multiple; Yarn 10, described yarn 10 is connected with single wheel 18 by static friction; False twisting...

Embodiment 2

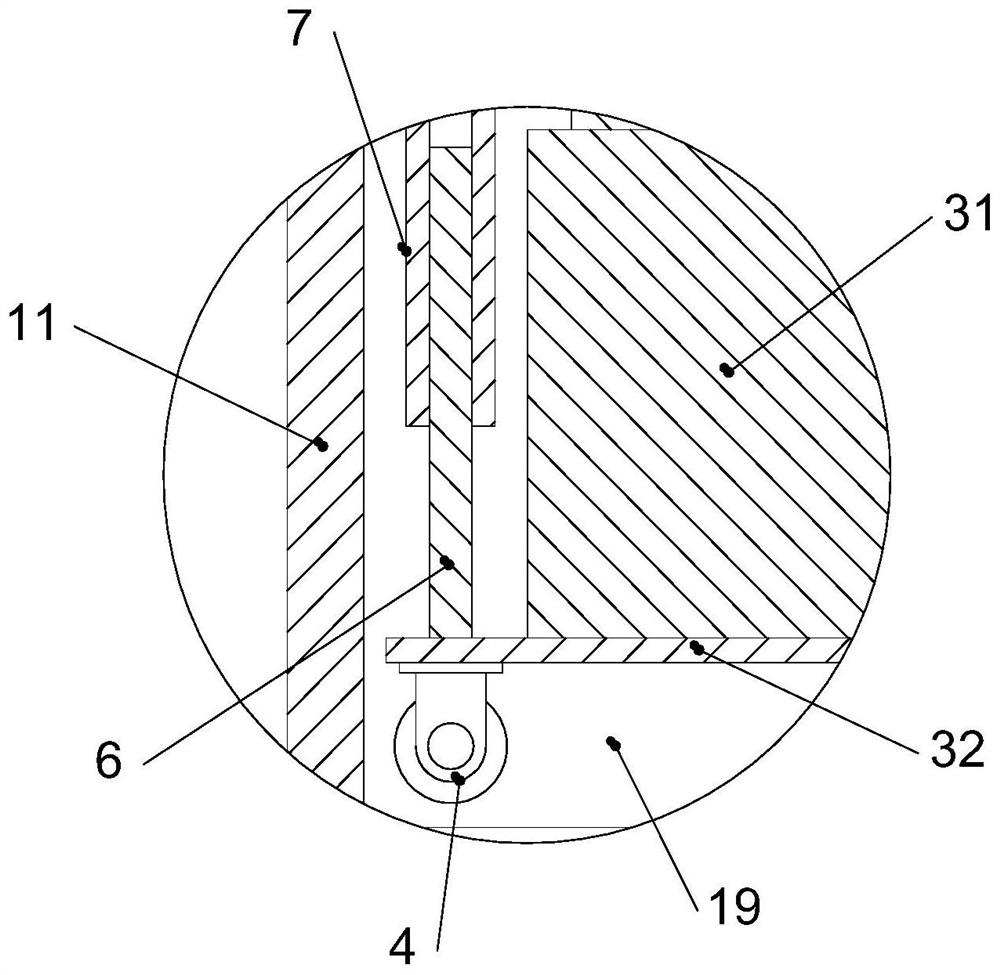

[0035] like image 3 As shown, the bottom of the body 11 is fixedly provided with an installation chamber 19, the installation chamber 19 is fixedly connected with a hydraulic lifting device 3, and the bottom of the hydraulic lifting device 3 is fixedly connected with a universal wheel with a self-locking function 4. The hydraulic lifting device 3 includes a hydraulic lifting column 31 and a mounting plate 32, the top of the hydraulic lifting column 31 is fixedly connected to the inner top surface of the installation chamber 19, and the mounting plate 32 is fixedly connected to the bottom of the hydraulic lifting column 31, The universal wheels 4 are fixedly connected to the four corners of the bottom surface of the hydraulic lifting column 31 by screws. In the present invention, the function of the hydraulic lifting device is as follows: ① the height of the body 11 can be adjusted by the hydraulic lifting device 3; ② after the universal wheel 4 is put down, the whole device ...

Embodiment 3

[0038] Embodiment 3: Improvement of adding a cluster in the drafting area

[0039] Spinning frame 1 is the main process to improve spinning quality and output, and process design, special parts configuration, and equipment operation status have a great influence on yarn quality. In order to improve the quality of the yarn 10, the present invention optimizes several aspects of the spun yarn collector, the type selection of the traveler 14, the design of the spindle speed, and the improvement of the drafting process.

[0040]In order to make up for the shortcoming of low final yarn strength caused by low spun yarn twist, the present invention installs a concentrator in the spun yarn process. The main function of the concentrator is to reduce the width of the fiber strands and arrange the floating fibers. The present invention is tested on a certain 18.2tex variety, and the spun yarn twist coefficient is designed to be 240. After the concentrator is installed, the yarn strength i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com