A High-Pressure Seal Flushing Tube Adaptable to Axial and Radial Offset

A high-pressure sealing and axial technology, which is applied in the direction of drill pipe, casing, and flushing wellbore, etc., can solve the problems of complicated installation and disassembly, insufficient spring compensation force, high coaxiality requirements for installation and operation, and solve the problems of complicated disassembly and installation, Reduce the effect of seal failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

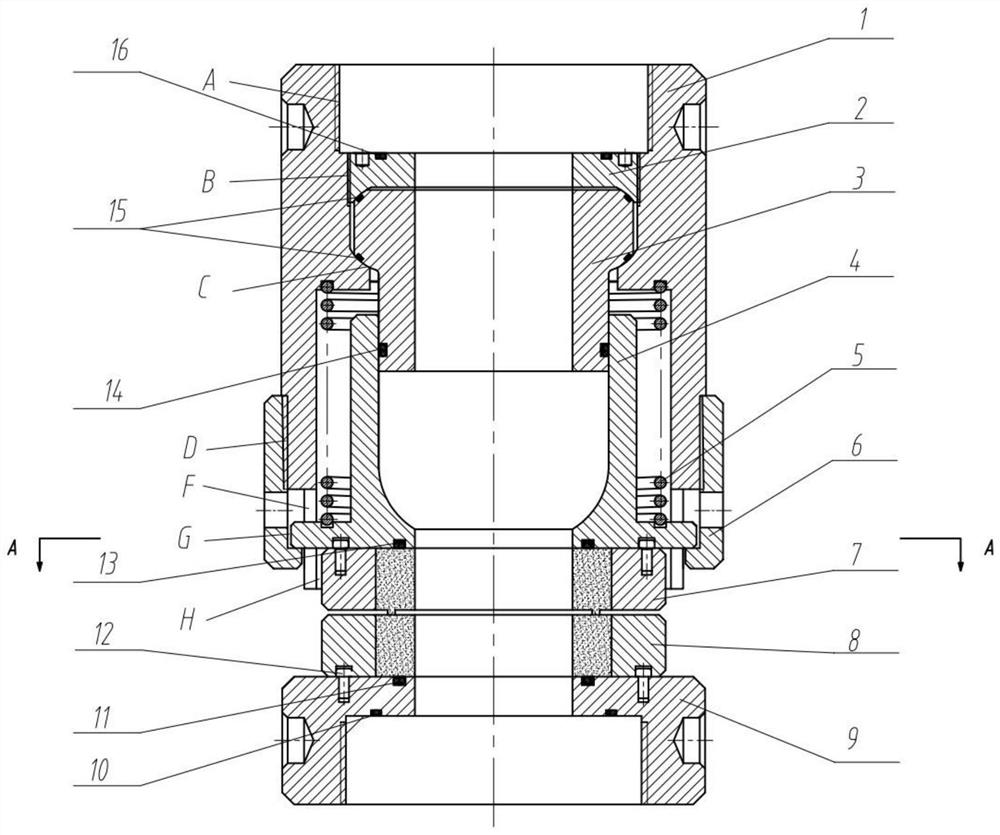

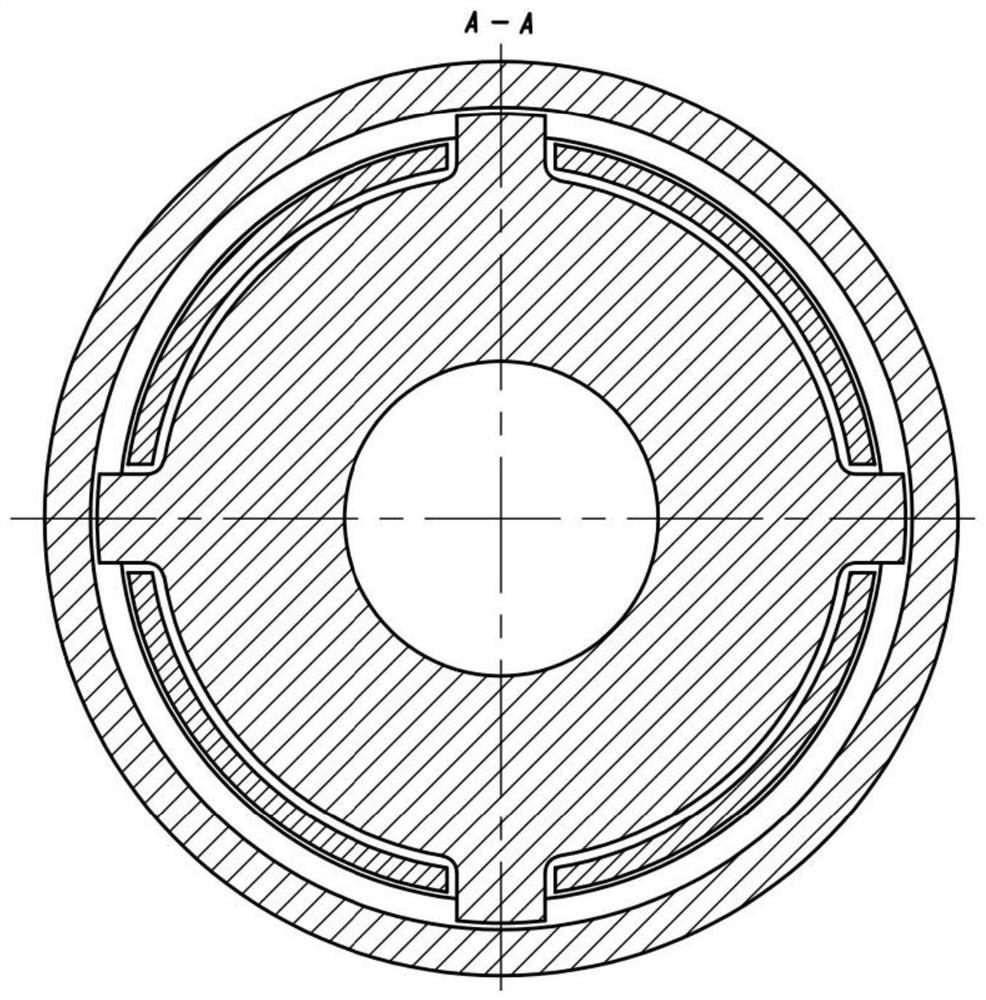

[0017] The present invention is not limited by the following implementation examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions. Combine below Figure 1~3 The present invention is described below.

[0018] Such as figure 1 Shown is the appearance of the flushing tube assembly of the present invention, the overall appearance of the mechanical seal flushing tube assembly is cylindrical, its structure is simple, easy to install and disassemble, and the spring compensation force is sufficient.

[0019] The specific structure of the present invention is as figure 2 As shown, the pipe flushing assembly mainly includes: 1 upper joint, 2 pressure plate, 3 center pipe, 4 pressure-bearing floating body, 5 built-in spring, 6 pre-tightening nut, 7 static ring, 8 moving ring, 9 lower joint, 10 lower joint sealing rings, 11 moving ring sealing rings, 12 anti-rotation pins, 13 static ring seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com