Rubber membrane combined valve element

A combined valve core and rubber diaphragm technology, which is applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of high risk of seal failure, unstable technical state, and complicated valve core processing technology, so as to improve the service life , to avoid incompatibility between the glue and the medium, and to stabilize the technical state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

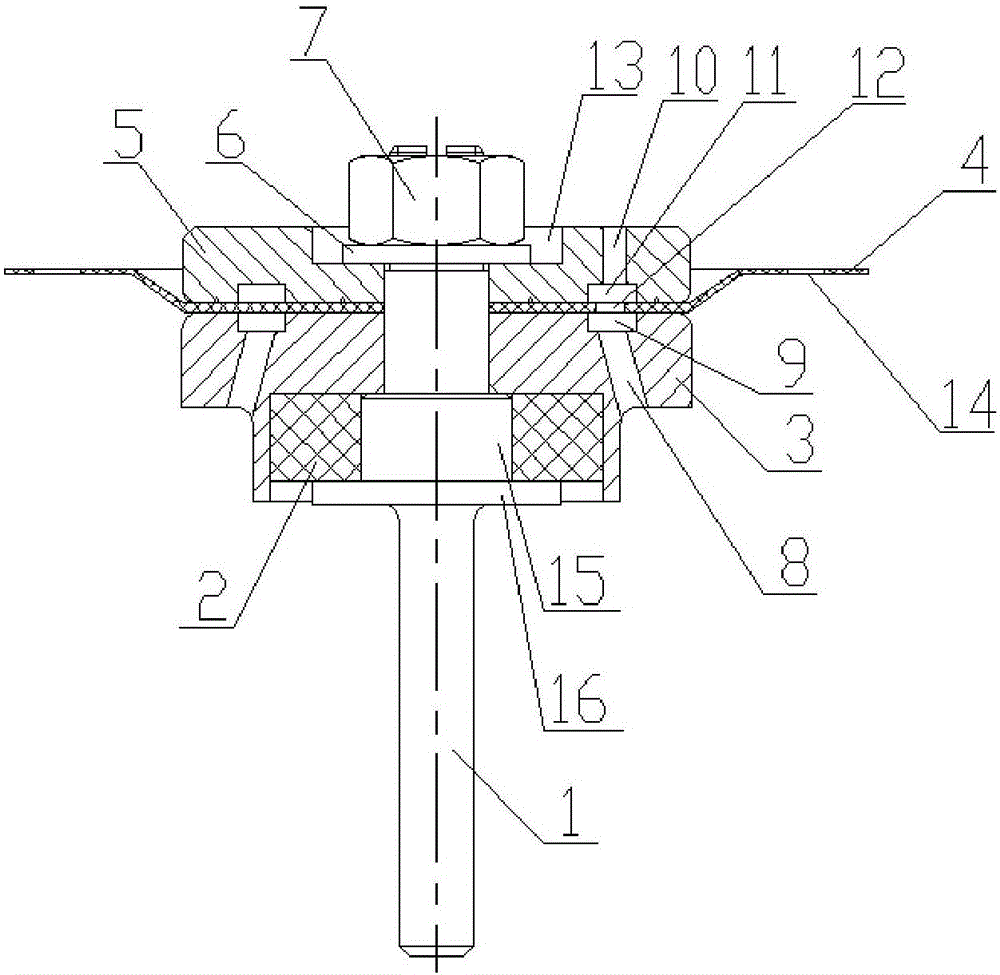

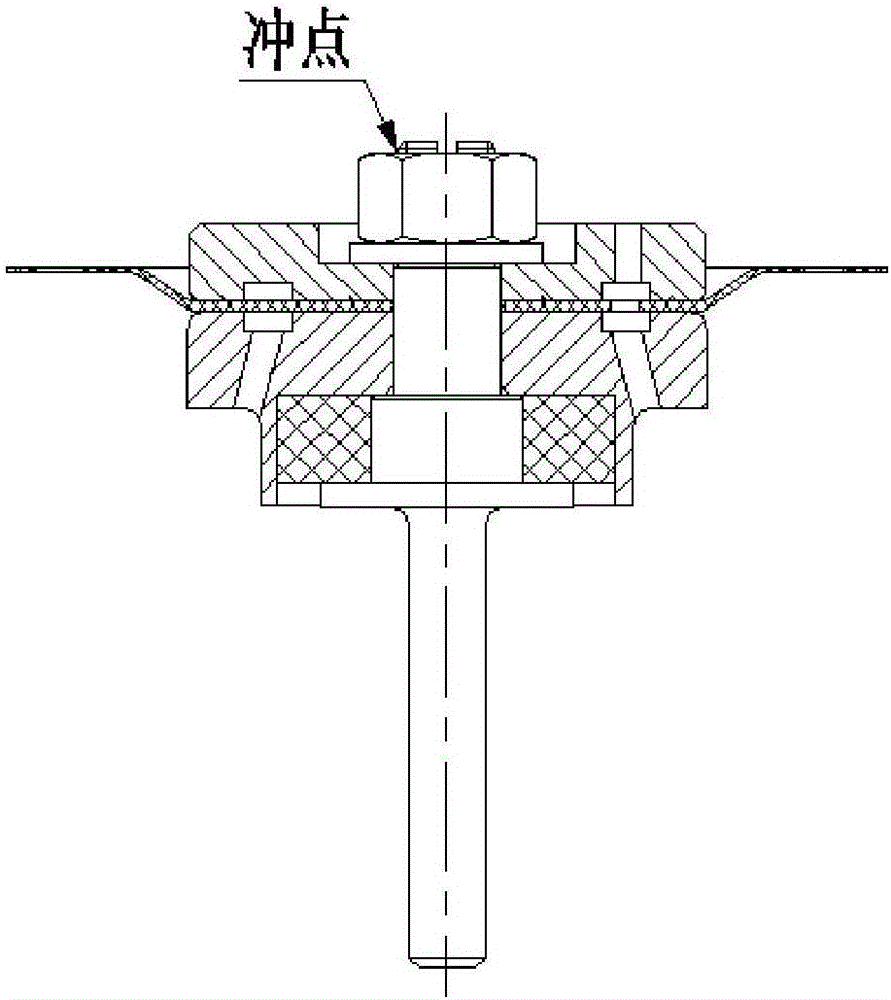

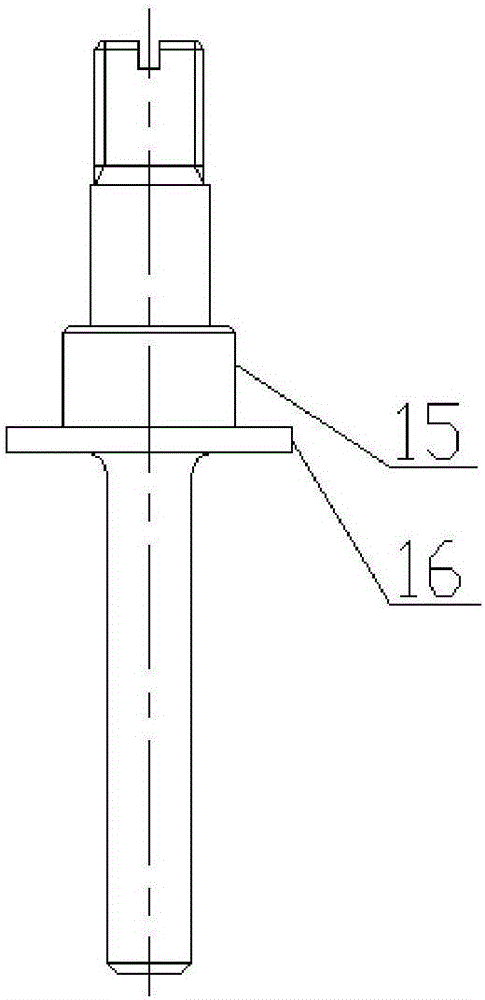

[0032] figure 1 Shown is the rubber diaphragm combination valve core of the present invention, and its assembly sequence is: rubber block 2, valve core 3, diaphragm 4, pressure ring 5 and spring washer 6 are installed on the valve stem 1 in sequence, and finally the nut 7 Press and fasten. Wherein, the rubber block 2 is installed outside the first limiting boss 15 in the middle of the valve stem 1, and is located in the valve core 3, and the compression deformation of the rubber block 2 is controlled by the first limiting boss 15 in the middle of the valve stem 1, The rubber block 2 is connected with the valve core 3 to form a valve core assembly. The lower end of the rubber block 2 is limited by the second limiting boss 16 to prevent it from falling off from the valve core 3 .

[0033] The diaphragm 4 of the present invention adopts a double-layer rubber cloth structure, has high strength and toughness, and has the advantages of large deformation, and the diaphragm 4 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com