Novel method for adjusting water injection rate of layer section in ultra-high water cut period of multi-layer heterogeneous sandstone reservoir

A technology for sandstone reservoirs in ultra-high water-cut periods, which is applied in the field of water injection volume adjustment in multi-layer heterogeneous sandstone reservoirs in ultra-high water-cut periods, and can solve problems such as inaccurate water injection adjustment schemes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

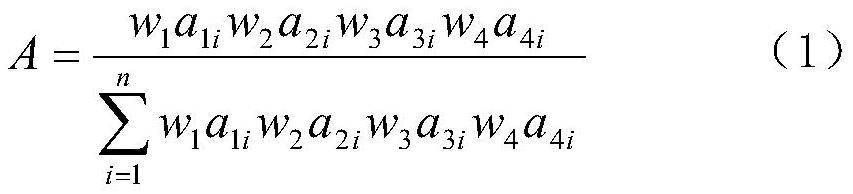

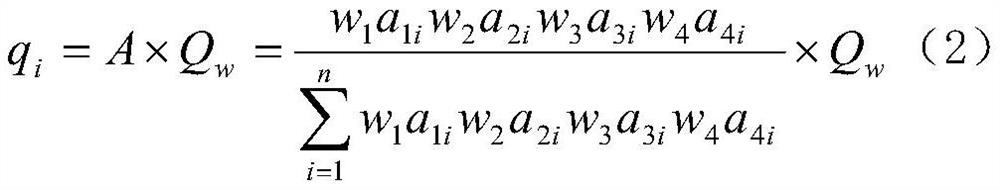

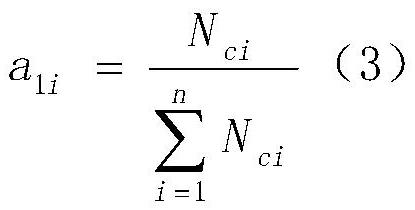

Method used

Image

Examples

Embodiment 1

[0050] Preferred embodiments of the invention are described in detail below, but the invention can be implemented in many different ways as defined and covered by the claims.

[0051] Utilizing the new method for adjusting the water injection volume of layered water injection wells in multi-layer heterogeneous sandstone reservoirs during the ultra-high water cut period of the present invention, this embodiment implements a water injection volume adjustment scheme for a water injection well S29 in the Z block of Daqing Changyuan Oilfield. Water injection well S29 is currently divided into 6 intervals, and the water injection volume of a single well is 135m 3 / d, establish the actual reservoir model of Block Z, and calculate the oil saturation, layered water injection rate, oil production rate and liquid production rate of each sub-layer in Well S29 by using reservoir numerical simulation and sub-layer production prediction software, namely The remaining reserves of layers, water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com