Tail gas treatment system for fuel train and control method of tail gas treatment system

A tail gas treatment and train technology, which is applied to the electric control of exhaust treatment devices, exhaust treatment, and diagnostic devices for exhaust treatment devices, etc., which can solve the problem of short maintenance period and poor soot treatment effect of fuel train exhaust treatment systems , Particle blockage and other problems, to achieve the effect of extending the maintenance cycle, ensuring normal operation, and prolonging the blockage cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Exhaust gas treatment systems for fuel trains in the prior art are usually single-channel, and a purification unit for purifying exhaust gas is arranged in the channel. The purification channel of the exhaust gas treatment system for fuel trains with this structure is extremely easy to be blocked by particles in the exhaust gas, and The treatment effect on the soot in the exhaust gas is poor, and the maintenance cycle of the exhaust gas treatment system for fuel trains is relatively short.

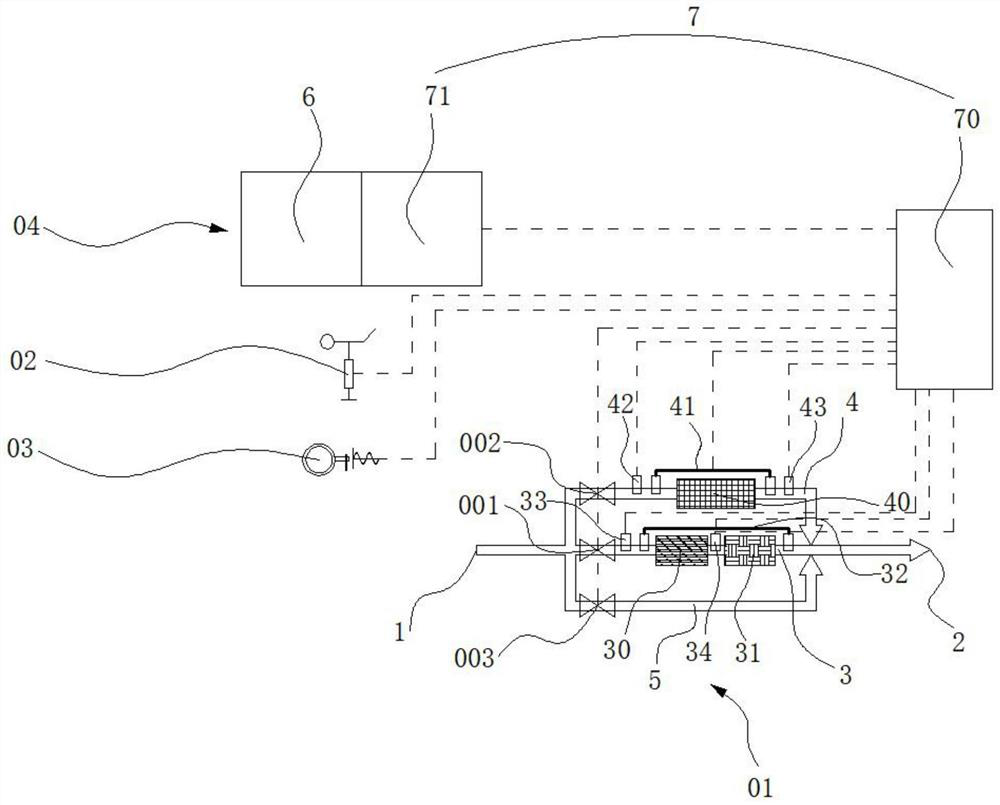

[0030] In view of the above technical problems, embodiment 1 provides an exhaust gas treatment system for fuel trains, such as figure 1 As shown, it includes: engine ignition switch 02, engine speed detector 03, exhaust processor 01 and human-computer interaction system 04.

[0031] The exhaust processor 01 includes an exhaust inlet 1 and an exhaust outlet 2; a main passage 3, a first bypass 4 and a second bypass 5 are arranged between the exhaust inlet 1 and the exhaust outlet 2, and...

Embodiment 2

[0058] Embodiment 2 also provides a control method for a fuel train tail gas treatment system, using the fuel train tail gas treatment system of embodiment 1, such as figure 1 shown, including:

[0059] Start-up phase (within 5 to 15 seconds after the engine starts): the control unit 7 receives "the engine ignition switch 02 is turned on, and the speed data of the engine speed detector 03 is less than the first threshold", and the control unit 6 controls the first bypass valve 002 is opened, the main passage valve 001 is closed, and the second bypass valve 003 is closed; at this time, the first bypass 4 is connected, and the main passage 3 and the second bypass 5 are closed. When the fuel train engine is just started, the exhaust gas with high concentration of particulate matter (PM) directly passes through the first bypass 4, and under the action of the diesel particulate filter (DPF) 40, the particulate matter (PM) in the exhaust gas is filtered and captured, which can signi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com