Polyethylene buried pipe risk evaluation method

A technology of risk assessment and polyethylene pipes, applied in resources, instruments, electrical digital data processing, etc., can solve the hidden dangers of residents, affect the normal transportation of natural gas and other problems, achieve the effect of being easy to operate in engineering and filling the gaps in risk assessment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

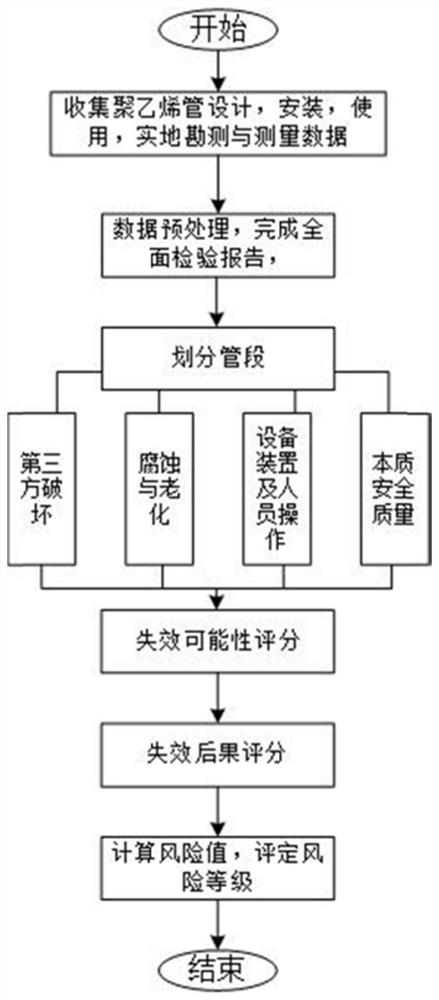

[0128] A risk assessment is required for a polyethylene pipeline in use, and the specific steps are as follows:

[0129] Step 1: In the initial stage of risk assessment, it is necessary to collect materials from the design, installation, and use of polyethylene pipelines, and complete a comprehensive inspection report according to steps 1 to 6 to provide data support for the scoring process.

[0130] Step 2: Review the evaluation polyethylene pipeline data and complete the data review report, mainly including: design specification, completion acceptance specification, commissioning date, pipeline start and stop position, pipeline length, design temperature, design pressure, pipeline specification, working medium, anti-corrosion layer, safety management data, technical file data, operating status data, last inspection report review, etc.

[0131] Step 3: Macroscopic inspection of polyethylene pipelines, mainly including: pipeline location and direction, ground warning devices, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com