Method for evaluating open-flow capacity of low-permeability gas reservoir gas well

An unblocked flow, gas well technology, applied in instruments, complex mathematical operations, data processing applications, etc., can solve the problems of long production test time, high cost, poor adaptability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a method for evaluating the open flow rate of a gas well in a low-permeability gas reservoir, including the following steps:

[0048] S1, Optimal productivity testing method: At present, common productivity testing methods include systematic well testing (back pressure testing), isochronous well testing, corrected isochronous well testing and one-point well testing. Each productivity testing method has its own pros and cons. A large amount of natural gas is vented during the system well test, which is a big waste; the isochronous well test takes too long to stabilize the pressure, which is not conducive to the economical and efficient development of the gas field; although the modified isochronous test shortens the test time and reduces the A certain cost, but for low permeability gas fields, there is still a long pressure stabilization time, and normal production cannot be performed during the test period; the one-point well test only needs one...

Embodiment 2

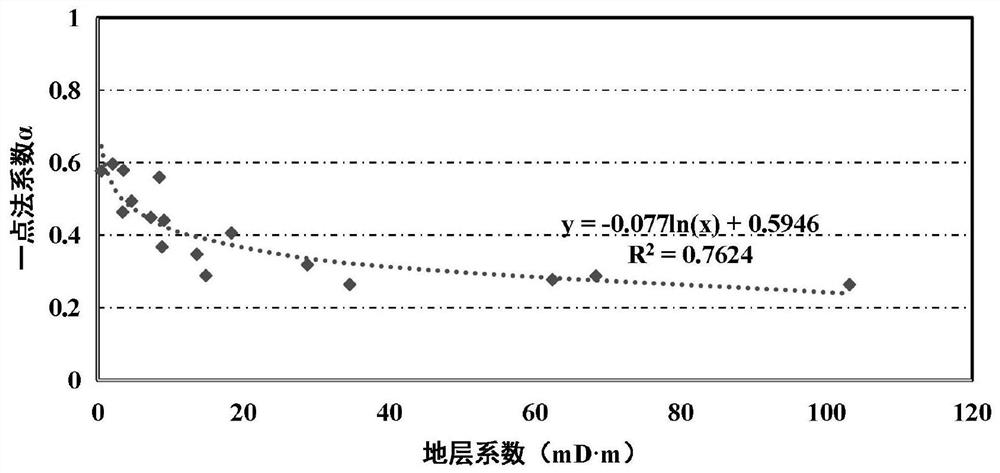

[0061] On the basis of Embodiment 1, further, the acquisition of the parameters of the one-point method production capacity formula in the step S2 specifically includes:

[0062] a, Acquisition of original formation pressure: The average daily gas production 30 days before the gas well is put into production is selected as the initial gas production of the gas well.

[0063] b. Acquisition of initial gas production of gas wells: According to the development experience of low-permeability gas fields, wellhead casing pressure and production tend to be stable 30 days after gas wells are put into production, so the average daily gas production 30 days before gas wells are selected as the initial gas production of gas wells.

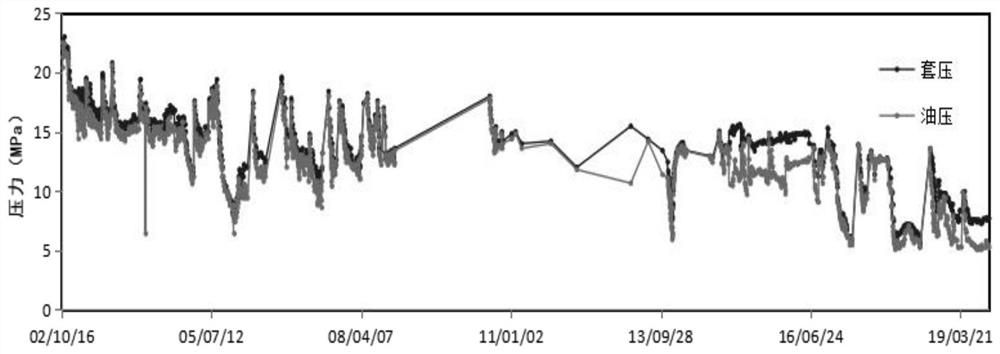

[0064] c. Acquisition of bottomhole flow pressure: According to the Cullender-Smith static gas column method, the well depth is divided into two parts, from the wellhead to the midpoint and from the midpoint to the bottom of the well, and the bottomhole pressu...

Embodiment 3

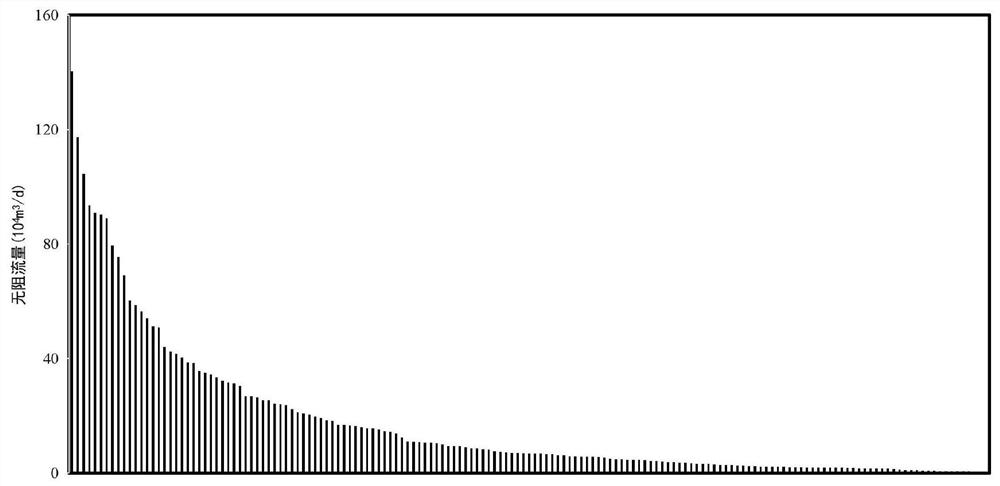

[0071] In this example, the typical block M of the paleo-low-permeability carbonate gas reservoir in the Jingbian gas field is taken as the target to be tested, and the unobstructed flow rate of all gas wells in the block is verified, and a method for evaluating the unobstructed flow of gas wells based on the conventional production data at the initial stage of the gas well is provided. The flow method includes the following steps (taking Well X in Block M as an example):

[0072] Step 1) Optimize productivity well testing method

[0073] In view of the long development time, heavy production tasks, and rich and comprehensive test data of the Jingbian Gas Field, combined with the low porosity and low permeability reservoir physical properties of the Jingbian Gas Field, and comprehensively considering the adaptability of different productivity testing methods, the one-point method was selected as the evaluation The production method of gas wells in Jingbian gas field.

[0074]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com