Composite snakelike flow channel structure, and all-vanadium redox flow battery containing same

An all-vanadium flow battery and flow channel technology, applied in fuel cells, regenerative fuel cells, circuits, etc., can solve problems such as uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

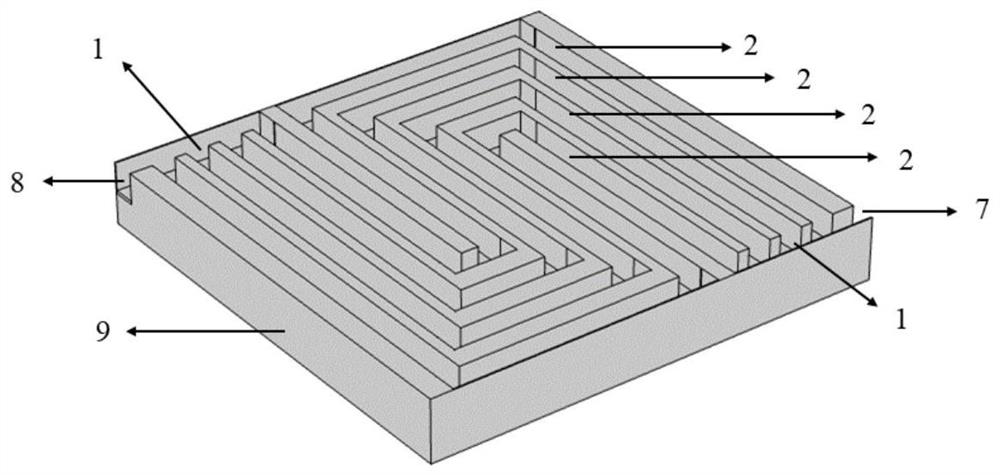

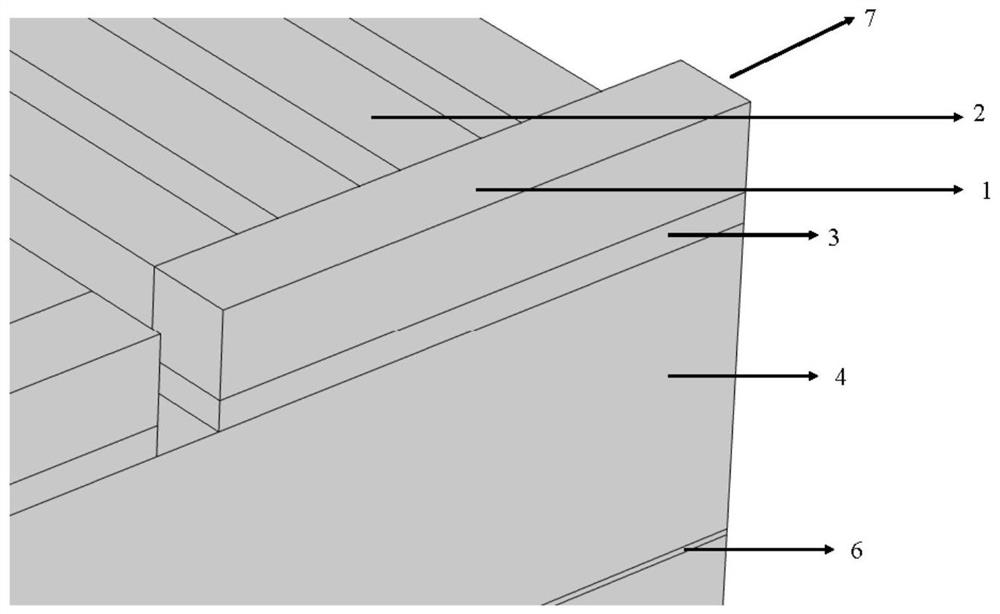

[0035] The thickness of the bipolar plate 9 is 4mm, the composite serpentine flow channel is engraved on the bipolar plate 9, the height of the main channel 1 is 2mm, the width is 1.5mm, the length of the first section and the tail section are both 9.75mm; the serpentine flow channel 2 The height is 1.8mm, the width is 1.5mm, and the length is 84.75mm; the distance between the two serpentine flow channels 2 is 0.75mm; the height of the reserved compression electrode space 3 is 0.2mm and the width is 1.5mm, that is, reserved The space height accounts for 10% of the height of the composite serpentine runner.

Embodiment 2

[0037] The thickness of the bipolar plate 9 is 4mm, the composite serpentine flow channel is engraved on the bipolar plate 9, the height of the main channel 1 is 2mm, the width is 1.5mm, the length of the first section and the tail section are both 9.75mm; the serpentine flow channel 2 The height is 1.5mm, the width is 1.5mm, and the length is 84.75mm; the distance between the two serpentine flow channels 2 is 0.75mm; the height of the reserved compression electrode space 3 is 0.5mm and the width is 1.5mm, that is, reserved The space height accounts for 25% of the height of the composite serpentine runner.

Embodiment 3

[0039] The thickness of the bipolar plate 9 is 4mm, the composite serpentine flow channel is engraved on the bipolar plate 9, the height of the main channel 1 is 2mm, the width is 1.5mm, the length of the first section and the tail section are both 9.75mm; the serpentine flow channel 2 The height is 1.3mm, the width is 1.5mm, and the length is 84.75mm; the distance between the two serpentine flow channels 2 is 0.75mm; the height of the reserved compression electrode space is 0.7mm, and the width is 1.5mm, that is, the height of the reserved space 35% of the height of the composite serpentine runner.

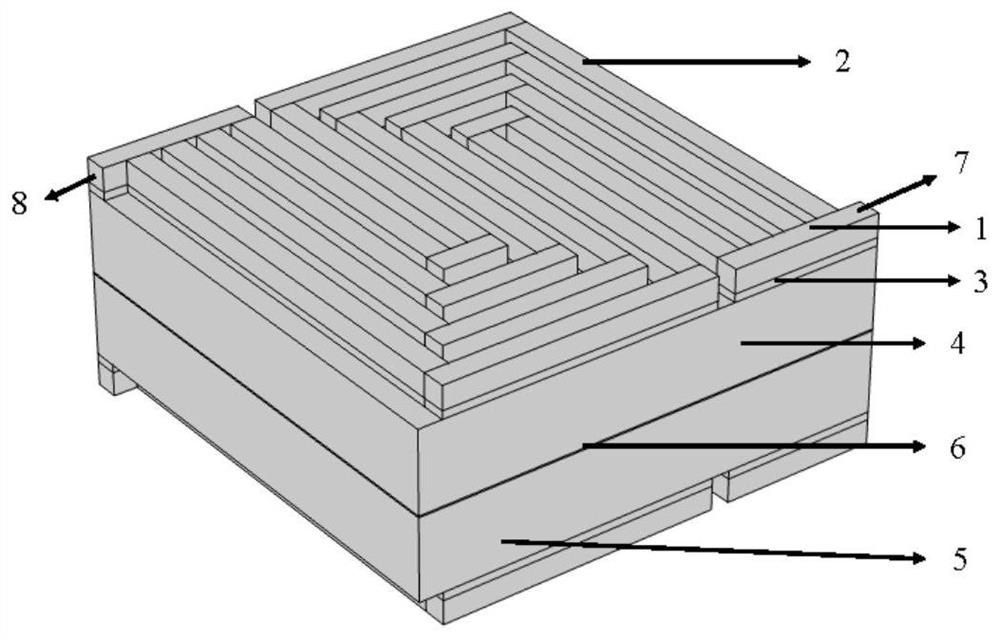

[0040] Based on the above-mentioned composite serpentine flow channel, the present invention also proposes an all-vanadium redox flow battery, comprising a bipolar plate 9, a negative electrode 4, a proton exchange membrane 6, and a positive electrode 5, and the above-mentioned composite serpentine flow channel is etched on the bipolar plate 9 structure.

[0041] The installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com