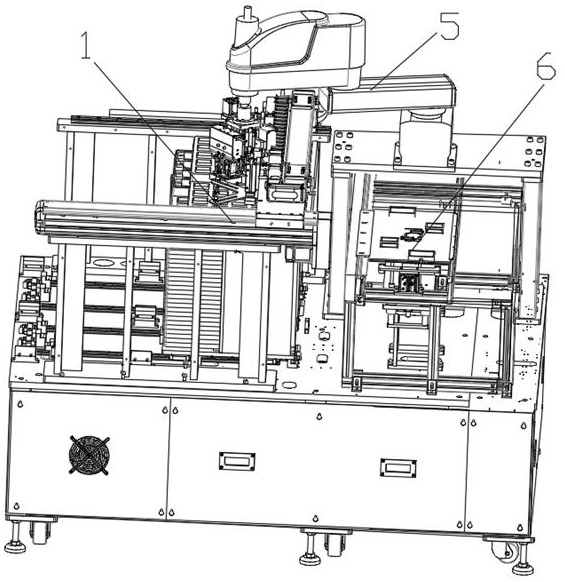

Display module assembly process of high-definition display screen

A technology of display module and assembly process, applied in the direction of identification devices, electrical components, instruments, etc., can solve the problems of low relative efficiency, inability to realize standardized product efficiency and time duration of the manufacturer's production line operation, and achieve good market application value, Labor saving, production needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

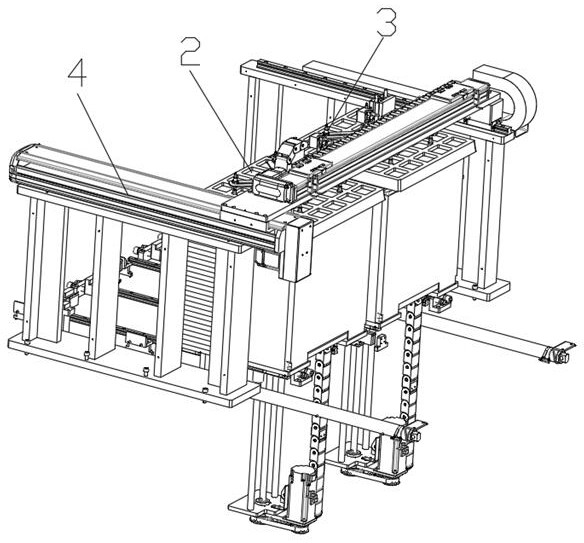

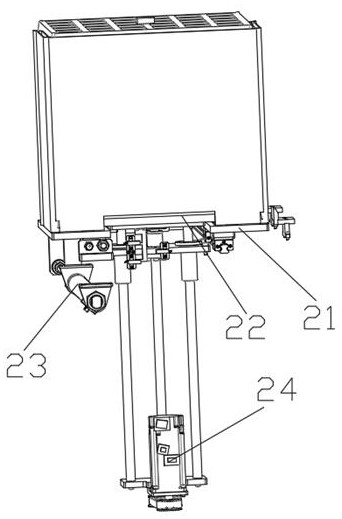

[0054]The display module assembly equipment for a high-definition display screen of this embodiment is different from that of Embodiment 1 in that the feeding mechanism includes a tray feeding part 1, a tray feeding part 2, a tray feeding part 3 and a moving The tray part, the second tray feeding part is arranged on the rear side of the tray feeding part one, the tray feeding part three is arranged on the rear side of the tray feeding part two, and the tray feeding part one , pallet feeding part two and pallet feeding part three are all arranged within the stroke range of the moving plate part; preferably, the pallet feeding part one, pallet feeding part two and pallet feeding part three have the same structure , realize the feeding of lamp bead 1 through tray feeding part 1, realize the feeding of lamp bead 2 through tray feeding part 2, realize the feeding of lamp bead 3 through tray feeding part 3, lamp bead 1, Lamp bead 2 and lamp bead 3 correspond to RGB single-color lamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com