Deep sea fishery breeding ship

A deep-sea fishery and ship technology, applied in animal husbandry, fish farming, special-purpose ships, etc., can solve problems such as structural plastic damage, ship danger, and chaotic arrangement of reinforcement ribs, to achieve enhanced horizontal and vertical strength, space The effect of high utilization rate and compact hull structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the following examples.

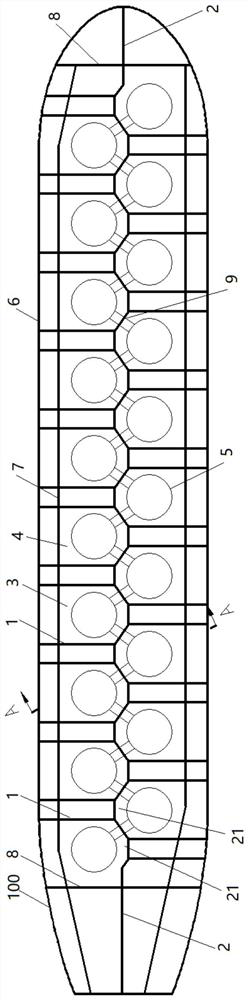

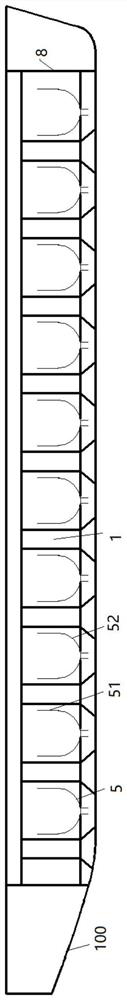

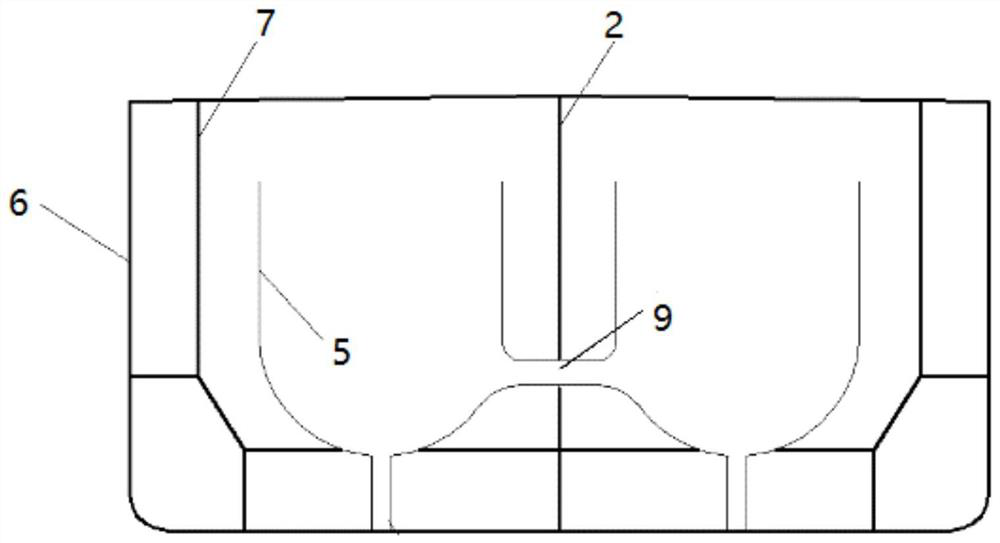

[0052] see Figure 1-3to understand. An embodiment of the present invention provides a deep-sea fish farming vessel, which is especially suitable for fish farming. The deep-sea fish farming vessel includes a hull 100, which constitutes the space required for farming. The hull 100 includes an isolation bulkhead 1 and a longitudinal bulkhead 2; several rows of farming areas 3 are separated in the hull 100, and each farming area 3 carries out farming operations independently. The "independent" here is for farming operations, and does not mean Absolute isolation of adjacent breeding areas 3 in space, in other words, adjacent breeding areas 3 can be completely isolated in space, and pipelines can also be set in space to realize interconnection, and the connection of the pipelines does not affect the two breeding areas 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com