Paddy field land leveling and weeding machine

A weeding machine and land leveling technology, applied in the field of agricultural tools, can solve problems such as obstacles to the promotion and implementation of new agronomy, unfavorable seedling growth, and influence on land utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

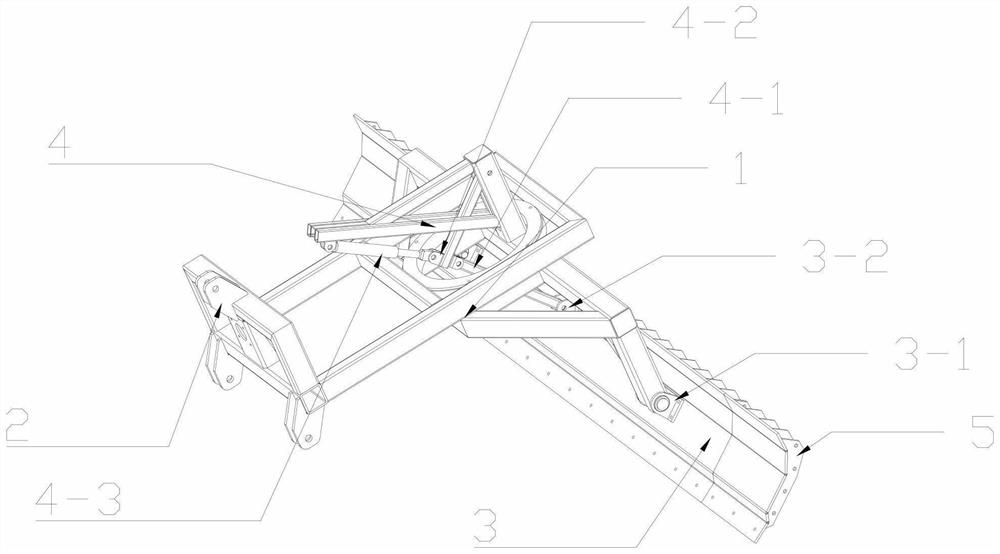

[0025] Such as figure 1 As shown, a paddy field level ground weeder includes a frame 1, the frame 1 is made of a hard material (such as steel), and the front end of the frame 1 is provided with three articulated points 2 arranged in the shape of a character , the articulation point 2 is used to realize the articulation of the frame 1 and the traction vehicle. At the end of the frame 1 opposite to the attachment point 2, a flat scraper 3 is provided. The cross section of the flat scraper 3 is a C-shaped structure, and the inner side of the C-shaped opening forms a concave surface of the flat scraper 3, and the concave surface of the flat scraper 3 The direction of the opening is the same as the direction of operation. A scraper hinge ear 3-1 and a mode adjustment ear 3-2 are fixed on the concave surface of the flat scraper. There is at least one scraper hinge ear 3-1. It is fixed on the frame 1 in a hinged form, so that the flat ground scraper 3 and the frame 1 are kept flat ...

Embodiment 2

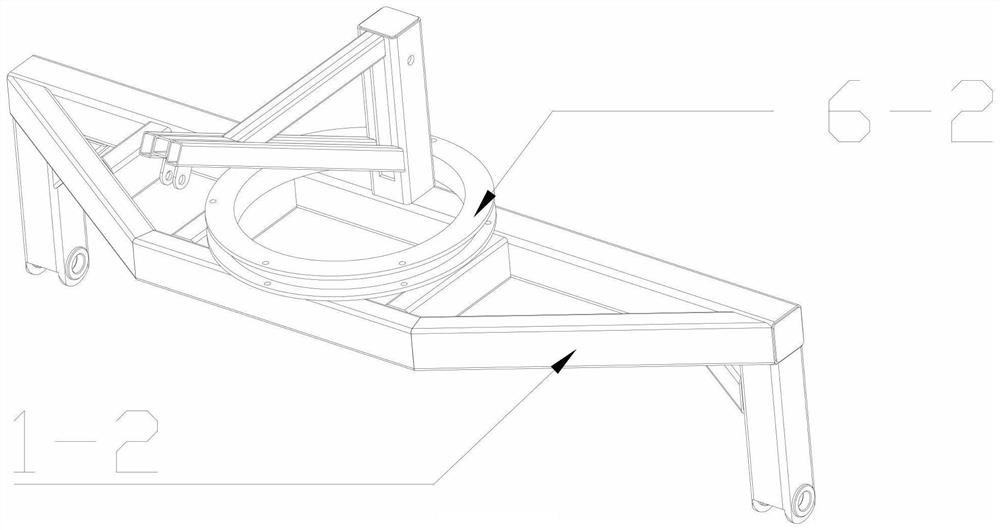

[0034] In order to reduce the resistance generated by the leveling scraper 3 during the traveling operation and facilitate the discharge of residual soil in a predetermined direction, this embodiment is realized by adjusting the vector of the leveling scraper 3 relative to the working direction. This embodiment 2 is based on the embodiment 1, and the frame 1 in the embodiment 1 is further improved, and it is designed to be composed of the first frame 1-1 and the second frame 1-2. .

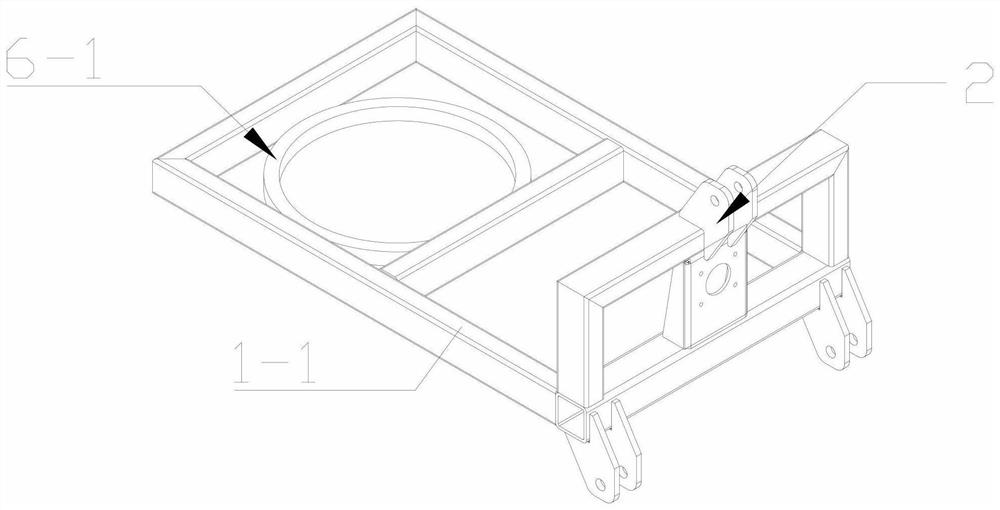

[0035] Such as figure 2 As shown, the first frame 1-1 is a rectangular frame structure, and the side adjacent to the towing vehicle is provided with a articulated point 2 arranged in the shape of a character, and the other side opposite to the articulated point 2 is provided with an outer frame. Ring 6-1. The second frame 1-2 is provided with an inner ring 6-2 matched with the outer ring 6-1, and the outer ring 6-1 and the inner ring 6-2 are nested to connect the first frame and the second mach...

Embodiment 3

[0041] In order to realize the ground profiling of the flat ground scraper 3 in this implementation force, on the basis of Embodiment 1 and Embodiment 2, in this embodiment, the attachment point 2 of the frame 1 or the first frame 1-1 and the traction vehicle The connection method is improved so that it can achieve ground profiling by twisting the direction during operation.

[0042] Since the traditional agricultural implement traction vehicles are all provided with the same layout as described in this application, the hitch point 2 is arranged in the shape of a character, and the independent hitch point located on the upper part is used for fixedly connecting the farm implement, which plays the role of stabilizing the farm implement and the lever fulcrum. An oil cylinder is respectively provided at the two symmetrically arranged mounting points at the lower part, and the oil passages of the two oil cylinders are connected in parallel, which act as lever power arms and are use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com