Drilling device facilitating high-altitude operation and having cleaning function

A drilling device and high-altitude operation technology, which is applied in the direction of drilling/drilling equipment, manufacturing tools, boring machines/drilling machine components, etc., can solve problems such as dust debris falling from high altitude, pedestrian danger, and increased safety hazards of high-altitude operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

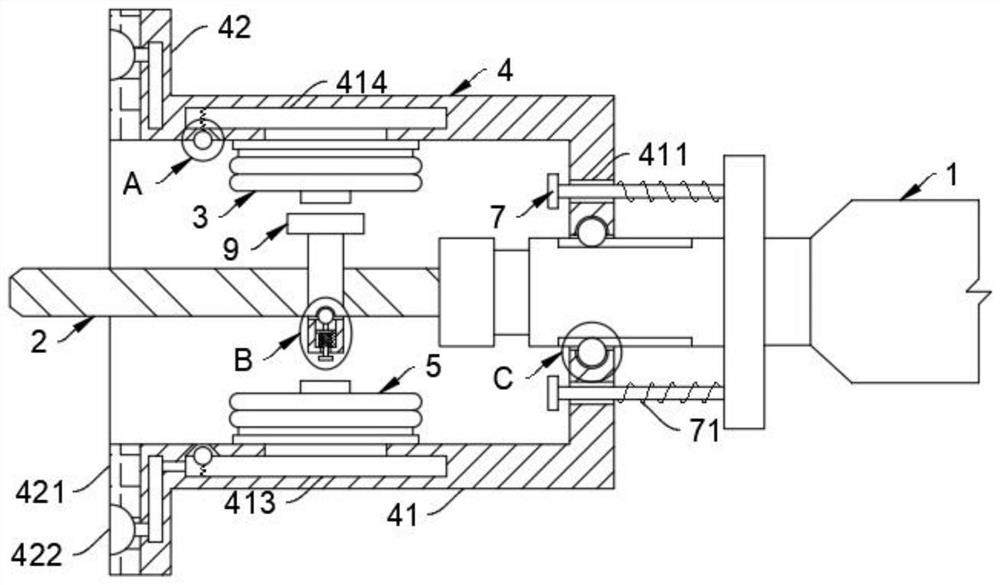

[0027] like Figure 1-5 As shown, a drilling device with a cleaning function that is convenient for high-altitude operations includes a drilling device body 1, and the drilling device body 1 is rotatably connected to a drill rod 2. It should be noted that the specific structure of the drilling device body 1 is uniform. It is a prior art, and has nothing to do with the innovation of the present invention. The drill pipe 2 is used to realize the drilling work for high-altitude operations.

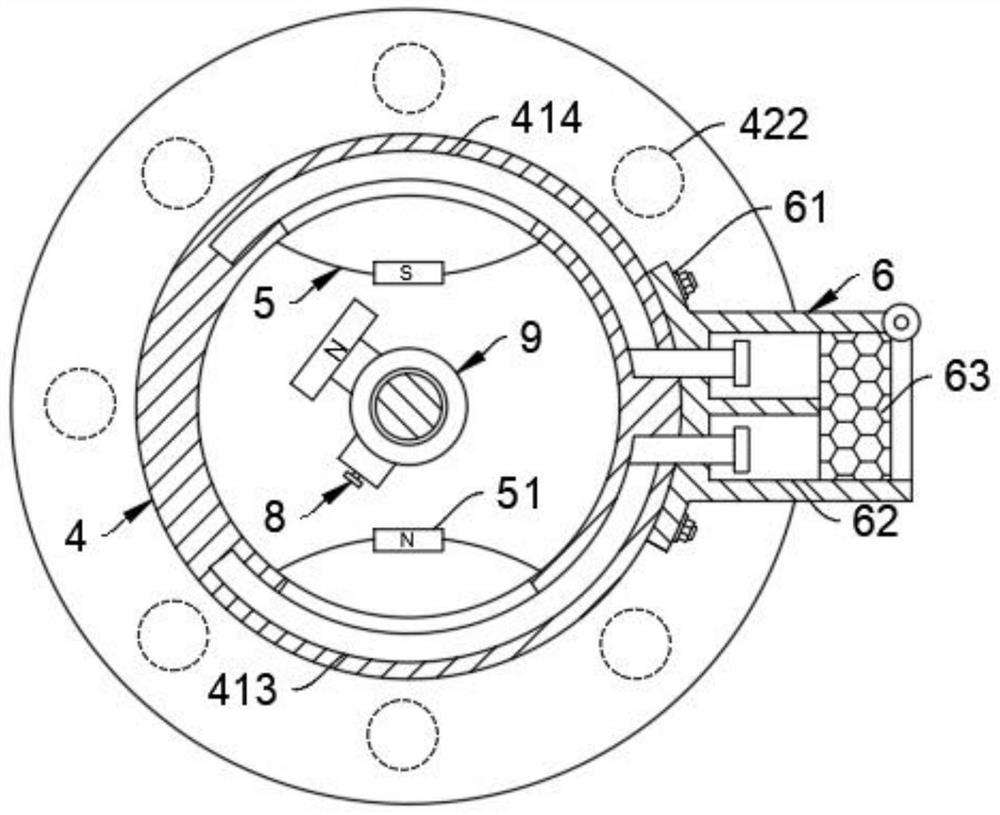

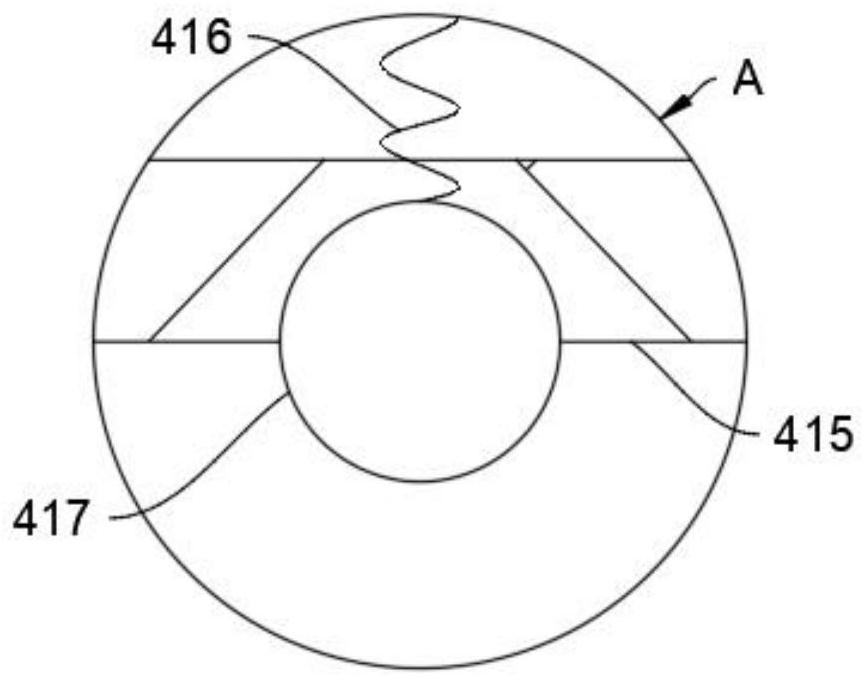

[0028] One end of the drilling device body 1 near the drill rod 2 is slidably connected with a cleaning assembly 3. The cleaning assembly 3 includes a sealing cover 4, an air bag 5 and a dust box 6. The sealing cover 4 is slidably connected with the drilling device body 1 through a positioning rod 7. It should be noted that the sealing cover 4 includes a tube body 41 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com