Universal tool jig for laser welding of multi-connection type food utensils

A laser welding and appliance technology, applied in the field of machinery and equipment, can solve the problems of inconvenient laser operation, lack of good tooling fixtures, poor welding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

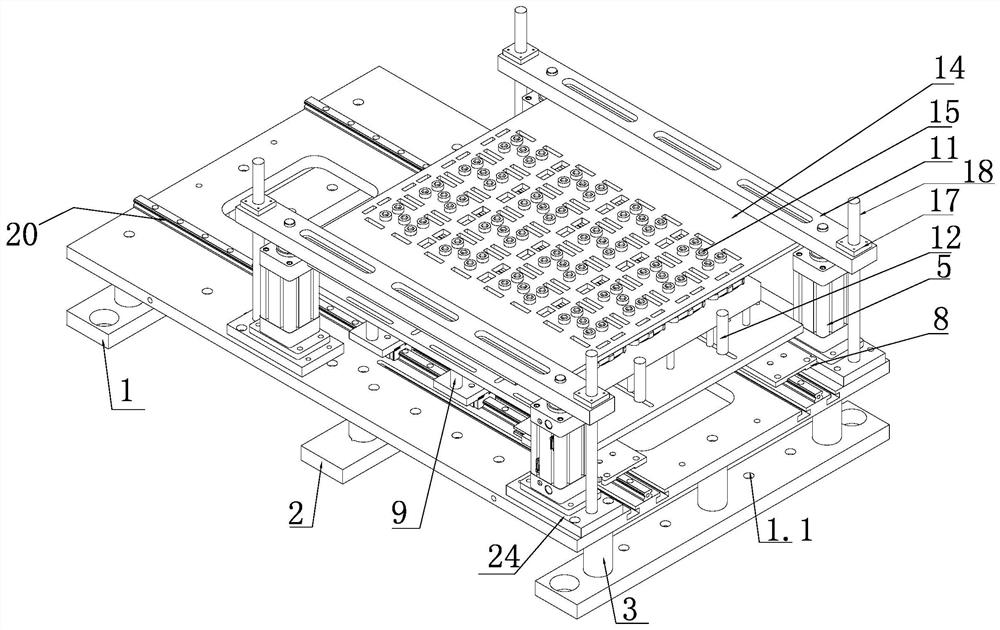

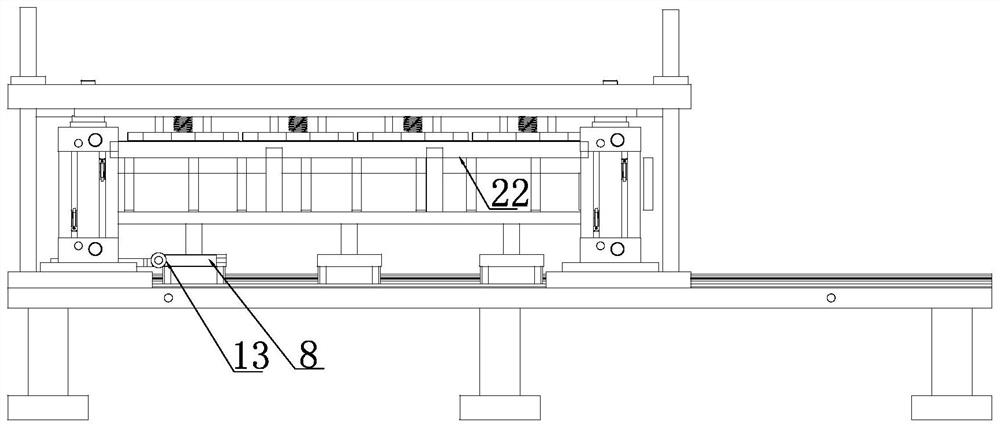

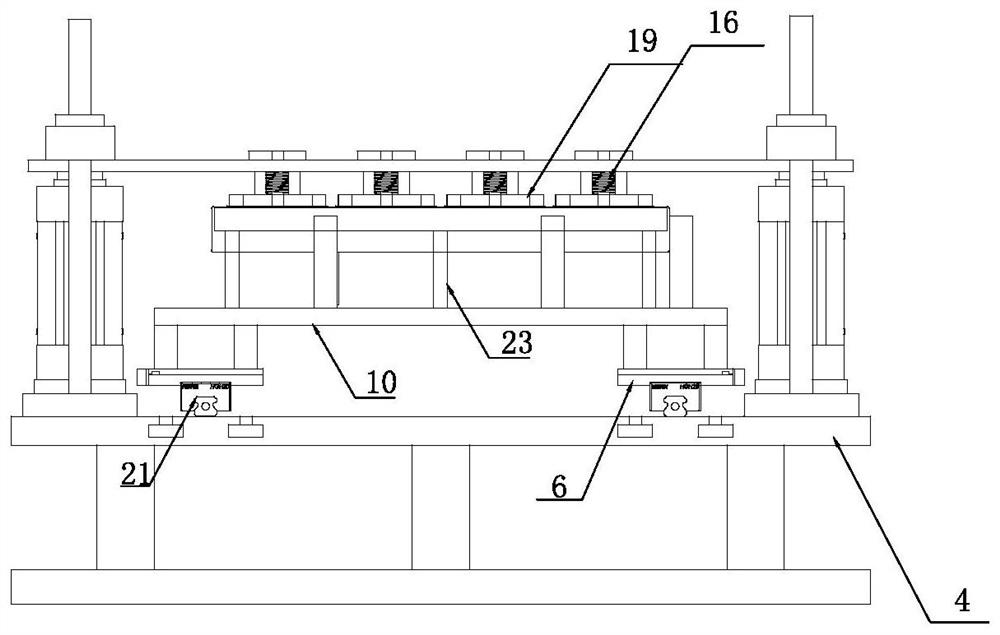

[0029] Such as Figure 1-6 Shown: a multi-connected food utensil laser welding universal tooling fixture, including a bottom plate 4, the bottom of the bottom plate 4 is connected with a plurality of bottom corner plates 1 side by side through bottom corner support legs 3 at intervals;

[0030] The upper surface of the bottom plate 4 is provided with two rows of guide rails 20 side by side along the length direction of the bottom plate at intervals, and each guide rail 20 is provided with three sets of slider assemblies and one set of fixed assemblies.

[0031] Wherein the top of the slider assembly and the fixed assembly are connected with the bottom of the support base plate 10 through the support column 9, and the support base plate 10 can slide along the guide rail under the drive of the slider assembly; the lower surface of food utensils;

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap