Main shaft capable of blocking nozzle and working method

A spindle and nozzle technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of large oil damping volume, low speed, insufficient lubrication of magnetic damping bearings, etc., and achieve the effect of quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] During the rotation of the main shaft in the prior art, since the nozzle is always open, when the nozzle is not working, the debris generated during the processing will recoil into the nozzle to block the nozzle, so it is necessary to design a valve that can block the nozzle. The main shaft of the nozzle, the specific structure is as follows:

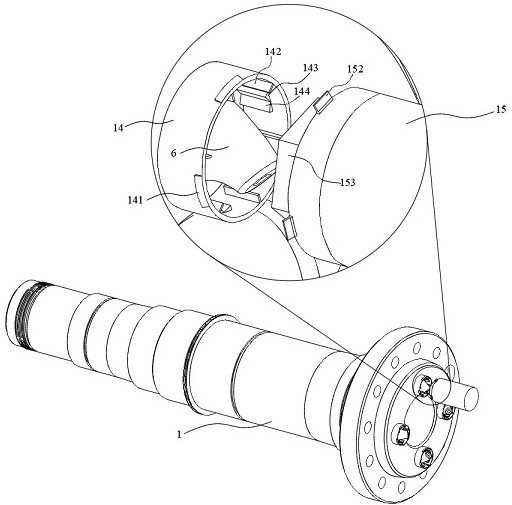

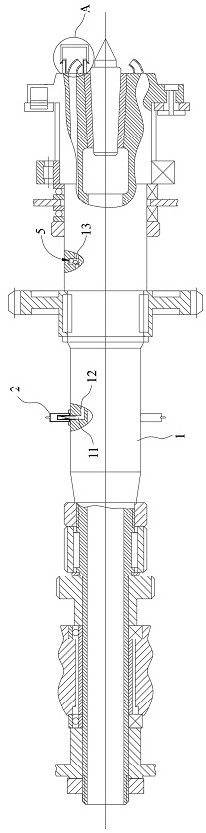

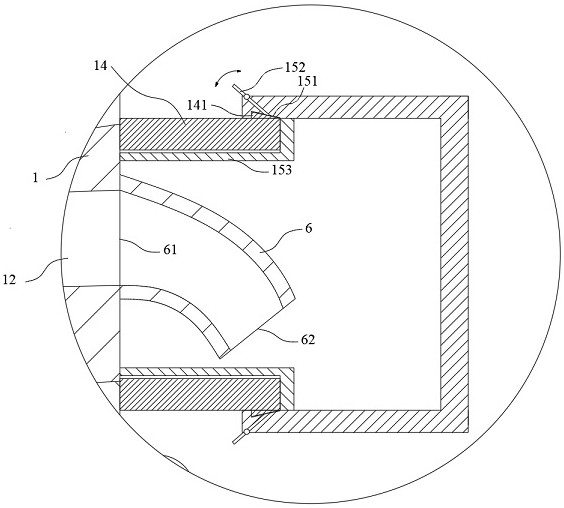

[0042] Main shaft body 1, the main shaft body 1 is a hollow structure, which has the following advantages: 1. The hollow main shaft body 1 is light in weight; 2. The hollow main shaft body 1 has high strength and is not easily deformed; 3. The hollow main shaft body 1 can reduce The driving force of the motor; a liquid injection groove 11 is opened in the middle of the main shaft body 1, and the liquid injection groove 11 extends radially from the outer wall of the main shaft body 1, so as to provide convenience for injecting cooling liquid into the main shaft body 1, correspondingly Compared with the method of feeding the coolan...

Embodiment 2

[0068] On the basis of the first embodiment, the second embodiment also provides a working method for the main shaft that can block the spout,

[0069] When the machine tool is adjusted to the cleaning state, the main shaft body 1 rotates at a high speed, and the cover body 15 is covered on the base 14 to block the nozzle 6, and the filter screen 24 is pushed by the right support plate 42 to shake off impurities, so that the cleaning brush 821 will Impurities are pushed into the blowdown box 81;

[0070] When the machine tool is adjusted to the working state, the main shaft body 1 rotates at a low speed, and the flow velocity of the coolant is increased by the left support plate 32 and the right support plate 42 moving closer to each other, and the vortex is formed through the stirring tank 13 to neutralize the coolant in each guide channel 12 ;

[0071] When the machine tool is adjusted to the pause state, the main shaft body 1 stops rotating, the cover body 15 is covered on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com