Automobile seat multi-stage inflation system and control method thereof

A technology for car seats and inflatable systems, which is applied to vehicle seats, pump control, vehicle components, etc., and can solve problems such as difficult manufacturing, complex structure, and loud switching valve noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

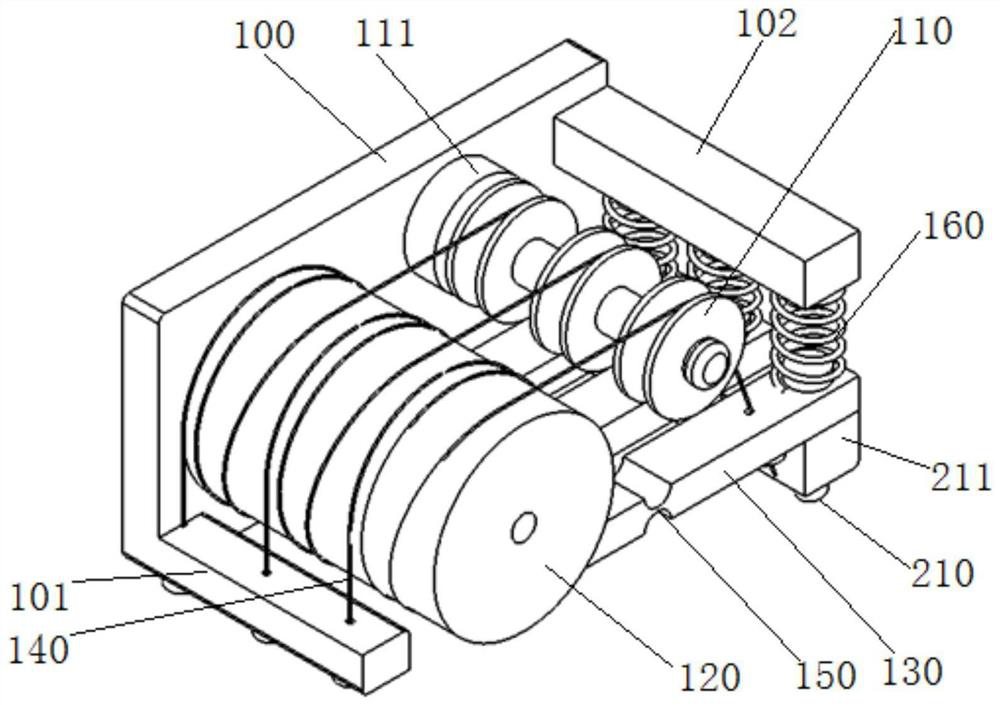

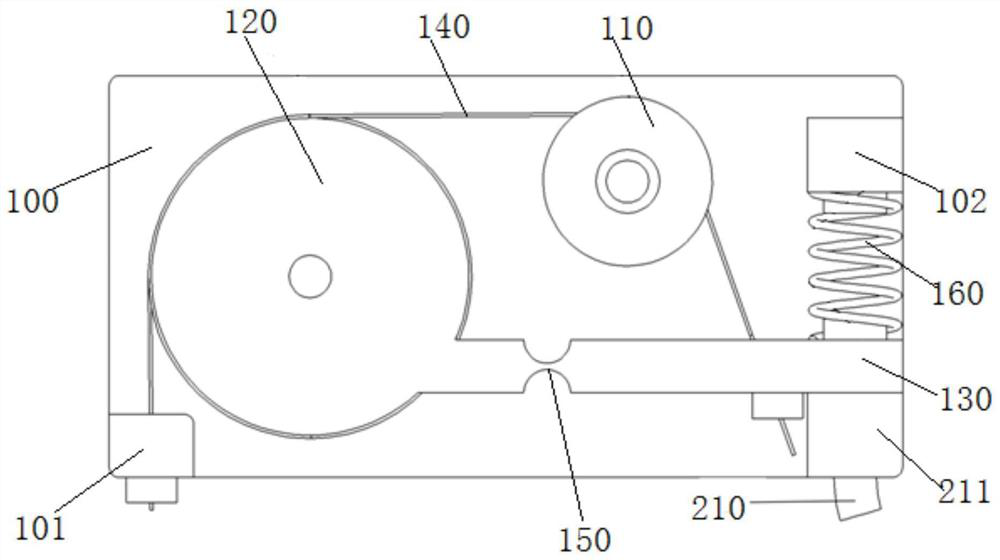

Method used

Image

Examples

Embodiment

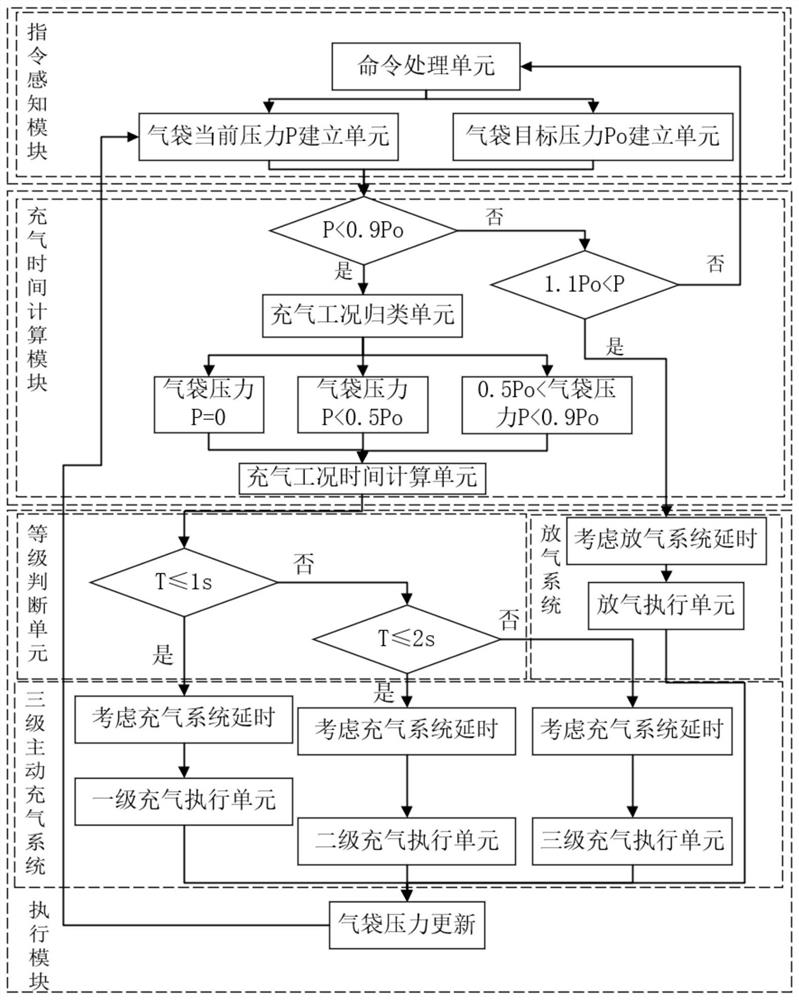

[0092] Such as Figure 3-5 As shown, in this embodiment, the numbers of the air pumps and the actuators are three respectively. The specific control method is as follows:

[0093] Compare the current air pressure P with the target pressure Po, and judge whether the current air bag pressure P is between 0.9-1.1 times the target pressure Po. If it is within this range, the air pump and actuator will not be turned on. If it is not within this range, then Turn on the air pump and actuator.

[0094] a. If the current airbag pressure P<0.9Po, the inflation working condition classification unit in the inflation time calculation module classifies the current airbag pressure, and calculates the time T for inflation to reach the airbag target pressure through the inflation working condition time calculation unit.

[0095] If T≤1s, on the basis of considering the delay of the system, connect 1 inflatable actuator and 1 air pump; when 1 inflatable actuator is connected, the actuator is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com